-16-

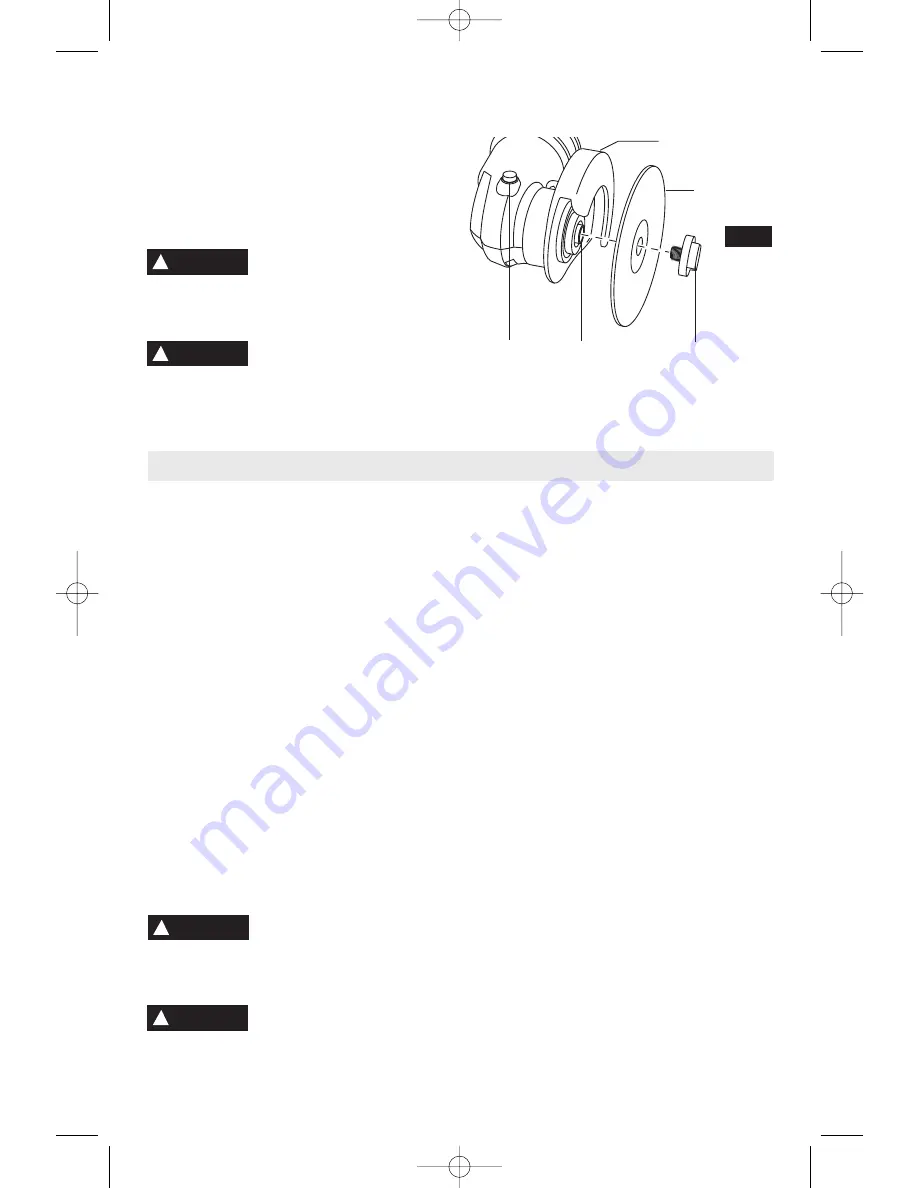

INSTALLING ABRASIVE WHEELS

Always use the arbor nut that has same

thread size as the output shaft.

1. Install abrasive wheel onto output shaft.

2. Thread arbor nut provided onto

output shaft finger tight, depress shaft lock

and tighten wheel with the wrench provided

(Fig. 4).

Do not overtighten. Cracks

in the wheel can occur if

overtightened. Use wrench provided with

tool. Other wrenches may promote

overtightening.

Do not depress shaft lock

while the tool is running.

Depressing the shaft lock may cause wheel

to spin off or damage to attachment.

!

WARNING

!

WARNING

GUARD

ABRASIVE

WHEEL

ARBOR

NUT

OUTPUT

SHAFT

SHAFT

LOCK

Operating Instructions

MAKING A CUT

1. Make sure material being cut is secured in

a vise or fixture before attempting to cut.

2. Keep your body positioned to either side of

the wheel, but not in line with wheel. It is

important to support the tool properly and to

position your body such as to minimize body

exposure from possible wheel binding and

recoil.

3. Grip the tool with both hands when cutting

and always be ready and able to manage the

cut.

4. Avoid jamming, twisting or pinching the

wheel with the workpiece or otherwise

applying excessive side pressure to the wheel.

5. Keep guard covering between wheel and

user.

6. Make sure the guard lock lever is in the

closed position and the guard is securely

mounted to the attachment. Use the allen

wrench to adjust the guard adjustment screw.

7. Maximum cutting depth is 11/16”.

Overtightening the guard

adjustment screw can

permanently damage the locking mechanism.

Test the tightness of the lever after each full

turn of the adjustment screw.

To prevent recoil and

damage to the tool, always

ensure that the inner or outer flanges never

contacts the workpiece surface.

8. Generally, the harder the material being

worked on, the faster the wheel will wear.

9. When cutting thicker material, never make

the cut in one pass. Make successive passes

until you reach desired depth.

10. When using the Diamond Wheel, do not

make long, continuous cuts. Allow the blade to

cool for approximately 10 seconds for each

minute cutting.

APPLICATIONS

This tool is intended for cutting the following

materials.

1/8˝ maximum thick sheet steel.

Floor and wall tile.

Concrete cinder blocks and bricks.

Reinforcing rod-generally under 5/8˝ diameter.

1/8˝ concrete wire mesh.

Electrical conduit 1/8˝ wall thickness.

1/8” maximum thick structural forms such as:

channels, angles, plate and etc.

ATTENTION: If you run the tool continuously

for more than 5 minutes, it is normal for the

housing to feel warm.

It is important to read and understand the

section in this manual called “Causes and

Operator Prevention of Recoil”.

FIG. 4

!

CAUTION

!

WARNING

RZ 2610954840 07-07 8/16/07 3:55 PM Page 16