-17-

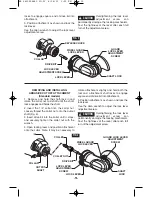

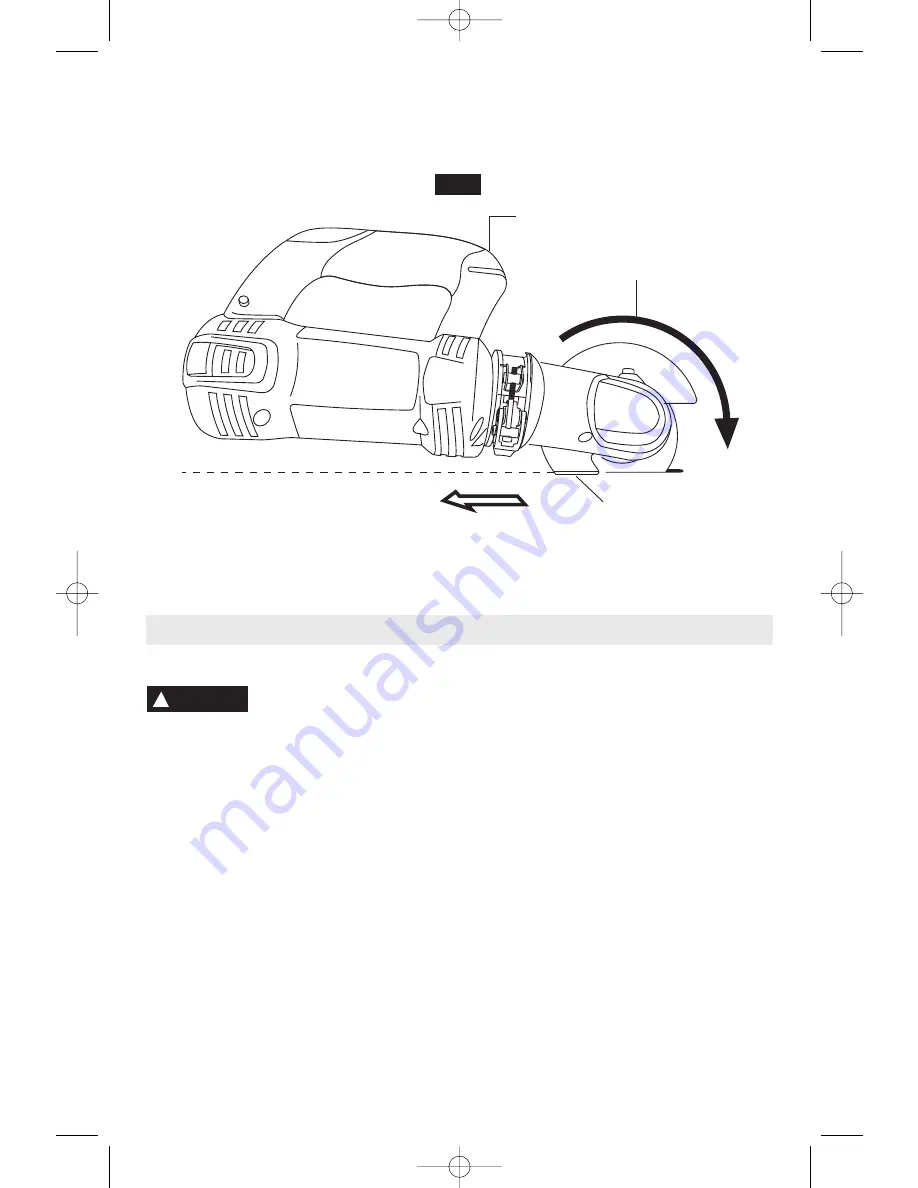

FIG. 5

FOOT

WHEEL

DIRECTION

DIRECTION OF CUT

HARD AUXILIARY

CONTROL HANDLE

When making a cut in sheet metal,

masonry, etc.: You may start your cut at the

end of the piece or you can plunge cut

somewhere in the body of the material.

In order to try to avoid recoil (a situation where

the wheel wants to skip out of the material) it

is recommended to make cuts in the same

direction as the rotation of the wheel (Fig. 5).

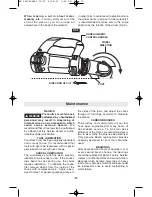

Service

Preventive maintenance

performed by unauthorized

personnel may result in misplacing of

internal wires and components which

could cause serious hazard. We

recommend that all tool service be performed

by a Bosch Factory Service Center or Autho-

rized Bosch Service Station.

TOOL LUBRICATION

Your Bosch tool has been properly lubricated

and is ready to use. It is recommended that

tools with gears be regreased with a special

gear lubricant at every brush change.

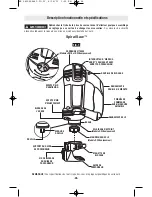

CHUCK LUBRICATION

The wrenchless chuck has been properly

lubricated and is ready to use. If the chuck's

jaws begin to stick during use, the chuck

requires lubrication. To lubricate the chuck,

first remove debris from the inside of the

chuck with compressed air. Apply a pea-

sized amount of general-purpose grease to

the sides of the jaws, and adjust the chuck

through its full range of motion to distribute

the grease.

CARBON BRUSHES

The brushes and commutator in your tool

have been engineered for many hours of

dependable service. To maintain peak

efficiency of the motor, we recommend every

two to six months the brushes be examined.

Only genuine Bosch replacement brushes

specially designed for your tool should be

used.

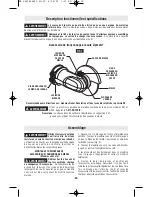

BEARINGS

After about 300-400 hours of operation, or at

every second brush change, the bearings

should be replaced at Bosch Factory Service

Center or Authorized Bosch Service Station.

Bearings which become noisy (due to heavy

load or very abrasive material cutting) should

be replaced at once to avoid overheating or

motor failure.

!

WARNING

Maintenance

RZ 2610954840 07-07 8/16/07 3:55 PM Page 17