-3-

Rotary Cutter Safety Rules

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

“ON” or “OFF”. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such

preventive safety measures reduce the risk of

starting the tool accidentally.

Store idle tools out of reach of children and

other untrained persons. Tools are

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind

and are easier to control. Any alteration or

modification is a misuse and may result in a

dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop a

periodic maintenance schedule for your tool.

Use only accessories that are recom-

mended by the manufacturer for your

model. Accessories that may be suitable for

one tool, may become hazardous when used

on another tool.

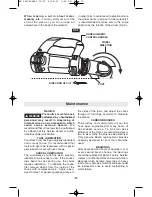

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard return springs may be

improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of

electric shock or injury. Certain cleaning

agents such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts.

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live"

and shock the operator.

If cutting into existing

walls or other blind areas where electrical

wiring may exist is unavoidable, disconnect

all fuses or circuit breakers feeding this

worksite.

Always make sure the work surface is free

from nails and other foreign objects.

Cutting into a nail can cause the bit and the

tool to jump and damage the bit.

Never hold the workpiece in one hand and

the tool in the other hand when in use.

Never place hands near or below cutting

surface. Clamping the material and guiding

the tool with both hands is safer.

Never lay workpiece on top of hard

surfaces, like concrete, stone, etc...

Protruding cutting bit may cause tool to jump.

Always wear safety goggles and dust

mask. Use only in well ventilated area.

Using personal safety devices and working in

safe environment reduces risk of injury.

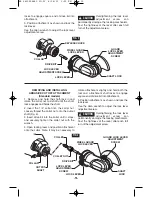

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are

securely tightened. Loose adjustment

device can unexpectedly shift, causing loss

of control, loose rotating components will be

violently thrown.

Never start the tool when the bit is

engaged in the material. The bit cutting

edge may grab the material causing loss of

control of the cutter.

RZ 2610954840 07-07 8/16/07 3:55 PM Page 3