FLAT WHEEL ASSEMBLy

Disconnect the plug from

the power source before

making any assembly, adjustments or

changing accessories. Such preventive safety

measures reduce the risk of starting the tool

accidentally.

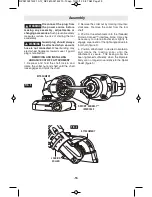

The Lock Bolt which attaches the cutting wheel

to the tool should be turned COUNTER-

CLOCKWISE to be loosened and CLOCKWISE

to be tightened (Fig. 5).

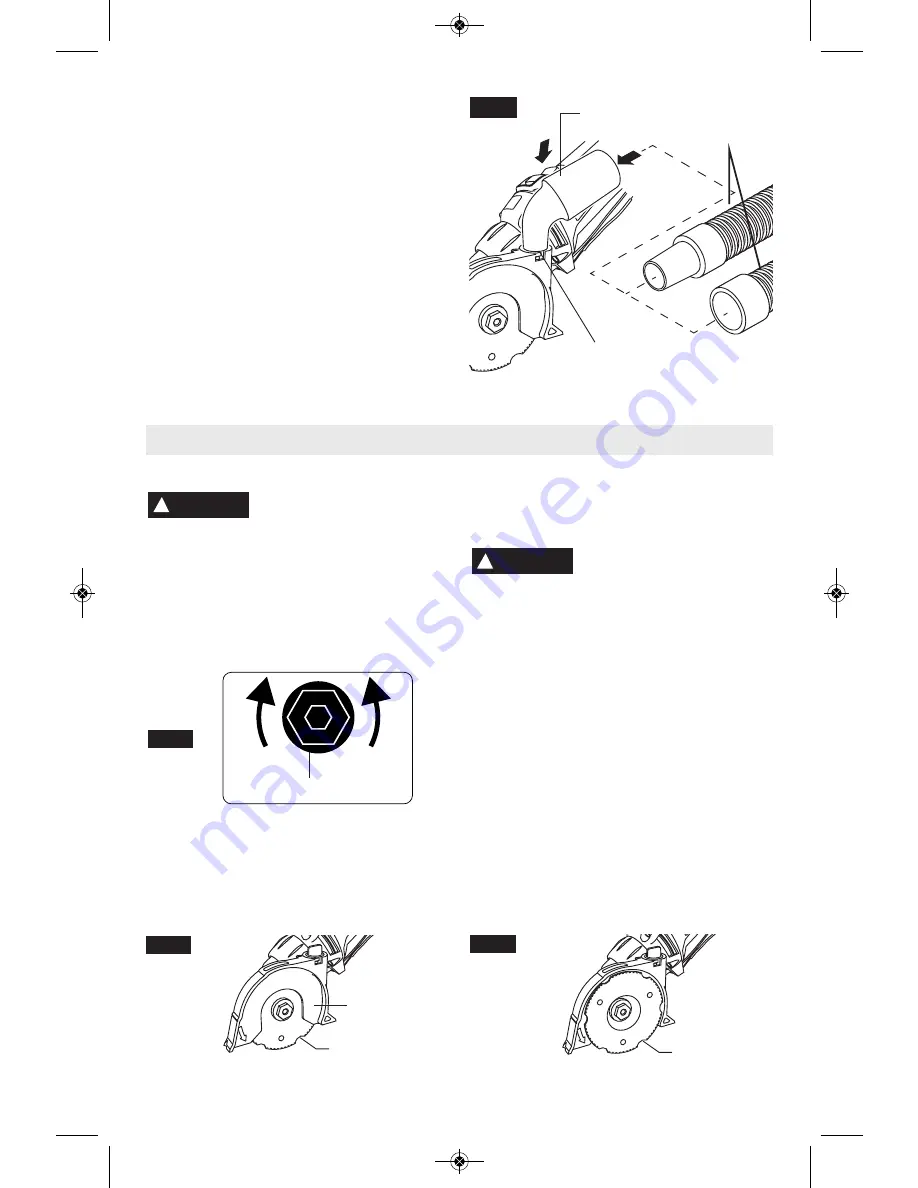

The ZM4 features two cutting wheel positions-

one position using a flat wheel for all your

typical straight and plunge cuts (Fig. 6), and a

second optional wheel position for making

flush cuts along flooring or against a wall

(Fig. 7).

Do not use flush cutting wheels for non-

flush cutting. The ZM4 does not have a

suitable guarding for straight cuts with

flush cut wheels.

Do not attempt to mount

two cutting wheels onto the

tool at the same time.

1. Turn LOCK BOLT with wrench provided

counter-clockwise and remove LOCK BOLT

and OUTER WASHER (Fig. 8). If the shaft

moves while attempting to loosen the lock

bolt press the spindle lock (Fig. 8).

2. Slide wheel behind the guard face and

mount it against the INNER WASHER on

the shaft (Fig. 6).

3. Reinstall OUTER WASHER and tighten lock

bolt finger tight.

4. Press spindle lock to lock shaft and tighten

LOCK BOLT clockwise until tight with the

wrench provided.

FLUSH CUTTING WHEEL ASSEMBLy

1. Repeat step 1 of above.

2. Place flush cutting wheel against the INNER

WASHER on the spindle shaft. (Fig. 7).

Assembly

!

WARNING

FLUSH

CUTTING WHEEL

!

WARNING

-20-

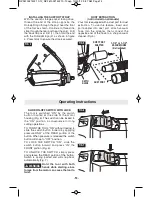

DUST ExTRACTION

(not included on all models)

Your ZM4 is equipped with a dust port for

dust extraction.

First remove the dust plug from the guard

(Fig. 1).

To use this feature, insert dust port adapter

into dust port, attach vacuum hose into the

adapter, then connect the opposite end of

the hose to a shop vacuum cleaner (Fig. 4).

FIG. 4

DUST PORT

ADAPTER

1-1/4" or 1-1/2"

VACUUM HOSE

(Not included)

DUST PORT

LOOSEN

TIGHTEN

LOCK BOLT

GUARD

FACE

FIG. 7

FLAT WHEEL

FIG. 5

FIG. 6

RZ 2610021432 10-12_RZ 2610021432 10-12.qxp 10/30/12 9:57 AM Page 20