-8-

of control. NEVER place your hand behind

the wheel since the tool may recoil over

your hand. Do not attempt to remove cut

material when wheel is moving. If both

hands are holding the tool, they cannot be cut

by the wheel.

Do not “jam” the abrasive wheel into the

work, apply excessive pressure or attempt

to use large depths of cut while using this

tool. Let the rotating wheel do the work,

Abrasive Cut Off Tools are intended to “cut”

the material in a series of shallow depth of

cuts. See the instructions for depth of cut later

in this manual.

Avoid bouncing and snagging the wheel,

especially when working corners, sharp

edges etc. This can cause loss of control and

tool’s recoil.

Do not run the tool while carrying it at your

side. Accidental contact with the spinning

wheel could result in serious personal injury.

Never lay the tool down until the motor has

come to a complete standstill. The spinning

wheel can grab the surface and pull the tool

out of your control.

Do not use the Zipmate near flammable

materials. Sparks from the wheel could ignite

these materials.

Never cut or attempt to cut magnesium

with this attachment. The dust generated

when cutting magnesium is highly flammable

and may be explosive under certain conditions.

Regularly clean the tool’s air vents by

compressed air. Excessive accumulation of

powdered metal inside the motor housing may

cause electrical failures.

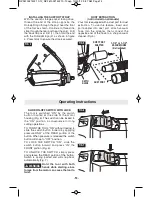

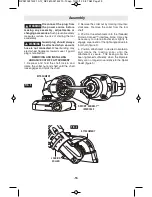

Causes and Operator

Prevention of Recoil:

Recoil is a sudden reaction to a pinched,

bound or misaligned rotating wheel. The wheel

may stall and cause an uncontrolled tool to

back out of the kerf toward the operator when

the tool is in the “fire forward” position, if the

tool is set in the “reverse fire” position the tool

may tend to walk away from the operator. The

rotation direction arrow located on the back

side of the guard can be used to identify the

“fire forward” and “reverse fire” positions. The

attachment is in the fire forward position when

the directional arrow points toward the

operator, and it is in the reverse fire position

when the arrow is pointing away from the

operator.

If an abrasive wheel or diamond wheel

becomes twisted or misaligned in the cut, the

side of the wheel that is entering into the

material can dig into the top surface of the

material causing the wheel to climb out or

recoil out of the kerf either toward or away

from the operator, depending on the fire

forward or reverse fire orientation.

Abrasive wheels may also shatter under these

conditions causing pieces or fragments to

strike or impale the operator and bystanders.

Recoil or shattered wheels are the result of tool

misuse and/or incorrect operating procedures

or conditions and can be avoided by taking

proper precautions as given below:

Maintain a firm grip with both hands on the

tool handles and position your body and

arm to allow you to resist recoil forces.

Recoil forces can be controlled by the

operator, if proper precautions are taken.

When wheel is binding, or when

interrupting a cut for any reason, slowly

ease the wheel out of the material while

maintaining a firm grip on the tool and

auxiliary handle with both hands.

Investigate and take corrective action to

eliminate the cause of wheel binding.

When restarting a tool in a workpiece,

center the wheel in the kerf and check that

the sides of the wheel are not engaged into

the material. If wheel is binding, it may walk

up or

recoil from the workpiece as the tool is

restarted.

Support large panels to minimize the risk of

wheel pinching and recoil. Large panels tend

to sag under their own weight. Supports must

be placed under the panel on both sides, near

the line of cut and near the edge of the panel.

Use extra caution when making a “Pocket

Cut” into existing walls or other blind

areas. The protruding wheel may cut objects

that can cause

recoil.

RZ 2610021432 10-12_RZ 2610021432 10-12.qxp 10/30/12 9:57 AM Page 8