Troubleshooting 2 SG9M

Manual

Troubleshooting

Eccentricity Problems when Cutting Three Angle Seats

:

Spindle floated to improper center location.

Excessive pressure when forming seat.

Incorrect spindle speed.

Worn or improperly selected pilot.

Worn Valve Guide.

Workhead base does not float

Concentricity is not with in the tolerance

Insufficient air pressure

Set air pressure of supplied line should be minimum 85 PSI ( 6 Bars)

Clamping plate does not drop when unclamped due to less clearance between upper floating base

and ball bearings mounted on clamping plate

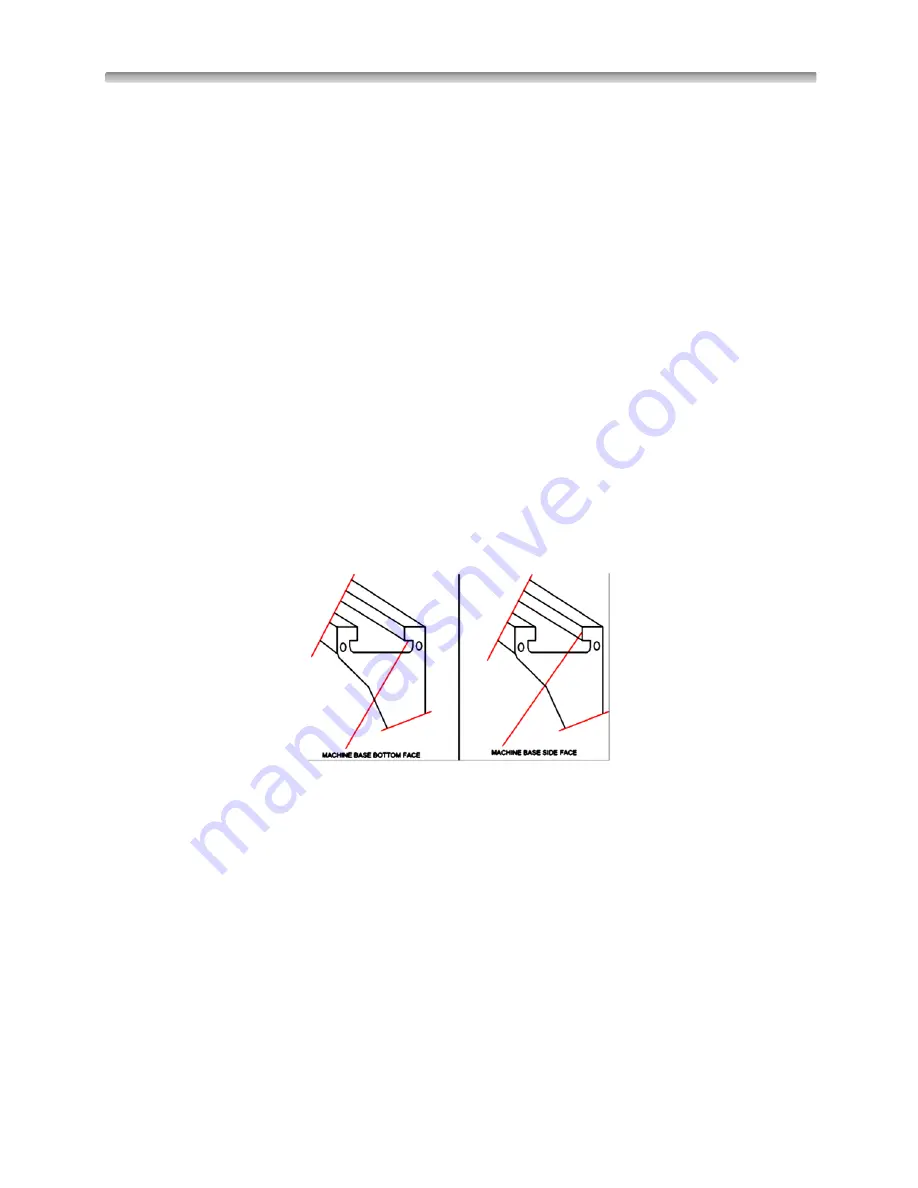

- Take the workhead to one end of the of the upper floating surfaces (Left or Right side) float the

workhead and pull it against the front on the T Slatted guide surfaces, then loose the set screws of the

eccentric pin to increase clearance by using a feeler gage of 0.008” to 0.010” (0.20mm to 0.25mm) in

between the T slotted guide surfaces of the upper base and the eccentric ball bearing; (see fig. below)

Lock the setscrews, remove the feeler gage and inspect if is with the tolerance across the all surfaces.

Repeat if it is necessary.

Summary of Contents for SG9M

Page 2: ......

Page 12: ...Introduction Safety Installation 9 SG9M Manual ...

Page 14: ...Introduction Safety Installation 1 SG9M Manual ...

Page 15: ...Control Definitions 1 SG9M Manual Chapter 2 Control Definitions SG9M Controls ...

Page 16: ...Control Definitions 1 SG9M Manual ...

Page 35: ...Operating Instructions 1 SG9M Manual ...

Page 39: ...Maintenance 1 SG9M Manual ...

Page 45: ...Troubleshooting 1 SG9M Manual ...

Page 51: ...Machine Parts 6 SG9M Manual WORKHEAD ASSEMBLY ...

Page 54: ...Machine Parts 9 SG9M Manual SPINDLE ASSEMBLY ...

Page 57: ...Machine Parts 12 SG9M Manual TRANSMISSION ASSEMBLY ...

Page 59: ...Machine Parts 14 SG9M Manual HEAD SUPPORT ASSEMBLY ...

Page 62: ...Machine Parts 17 SG9M Manual SG9M Pneumatic Drawing ...

Page 70: ...Options 1 SG9M Manual Options ...

Page 71: ...Options 2 SG9M Manual ...