Machine Parts

24

SG9M Manual

FRACTION

DECIMAL

MM

2 3/4

2.7500

69.8500

2 49/64

2.7656

70.2469

2 25/32

2.7813

70.6438

2 51/64

2.7969

71.0406

2 13/16

2.8125

71.4375

2 53/64

2.8281

71.8344

2 27/32

2.8438

72.2313

2 55/64

2.8594

72.6281

2 7/8

2.8750

73.0250

2 57/64

2.8906

73.4219

2 29/32

2.9063

73.8188

2 59/64

2.9219

74.2156

2 15/16

2.9375

74.6125

2 61/64

2.9531

75.0094

2 31/32

2.9688

75.4063

2 63/64

2.9844

75.8031

3

3.0000

76.2000

Summary of Contents for SG9M

Page 2: ......

Page 12: ...Introduction Safety Installation 9 SG9M Manual ...

Page 14: ...Introduction Safety Installation 1 SG9M Manual ...

Page 15: ...Control Definitions 1 SG9M Manual Chapter 2 Control Definitions SG9M Controls ...

Page 16: ...Control Definitions 1 SG9M Manual ...

Page 35: ...Operating Instructions 1 SG9M Manual ...

Page 39: ...Maintenance 1 SG9M Manual ...

Page 45: ...Troubleshooting 1 SG9M Manual ...

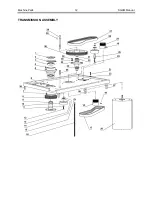

Page 51: ...Machine Parts 6 SG9M Manual WORKHEAD ASSEMBLY ...

Page 54: ...Machine Parts 9 SG9M Manual SPINDLE ASSEMBLY ...

Page 57: ...Machine Parts 12 SG9M Manual TRANSMISSION ASSEMBLY ...

Page 59: ...Machine Parts 14 SG9M Manual HEAD SUPPORT ASSEMBLY ...

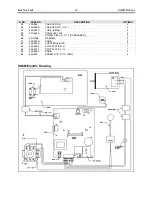

Page 62: ...Machine Parts 17 SG9M Manual SG9M Pneumatic Drawing ...

Page 70: ...Options 1 SG9M Manual Options ...

Page 71: ...Options 2 SG9M Manual ...