4

S

ection

2 — i

mportant

S

afe

o

peration

p

racticeS

13. If your machine is equipped with an internal combustion

engine and is intended for use near any unimproved forest,

brush, or grass covered land, the engine exhaust should be

equipped with a spark arrestor. Make sure you comply with

applicable local, state, and federal codes. Take appropriate

firefighting equipment with you.

14. This machine should be used for splitting wood only, do

not use it for any other purpose.

15. Follow the instructions in the manual(s) provided with any

attachment(s) for this machine.

Preparation

1.

Always wear safety shoes or heavy boots.

2.

Always wear safety glasses or safety goggles when

operating this machine.

3.

Never wear jewelry or loose clothing that might become

entangled in moving or rotating parts of the machine.

4.

Make sure machine is on a flat, dry, solid ground before

operating.

5.

Always block wheels to prevent unintended movement,

and lock beam in either the horizontal or vertical position.

6.

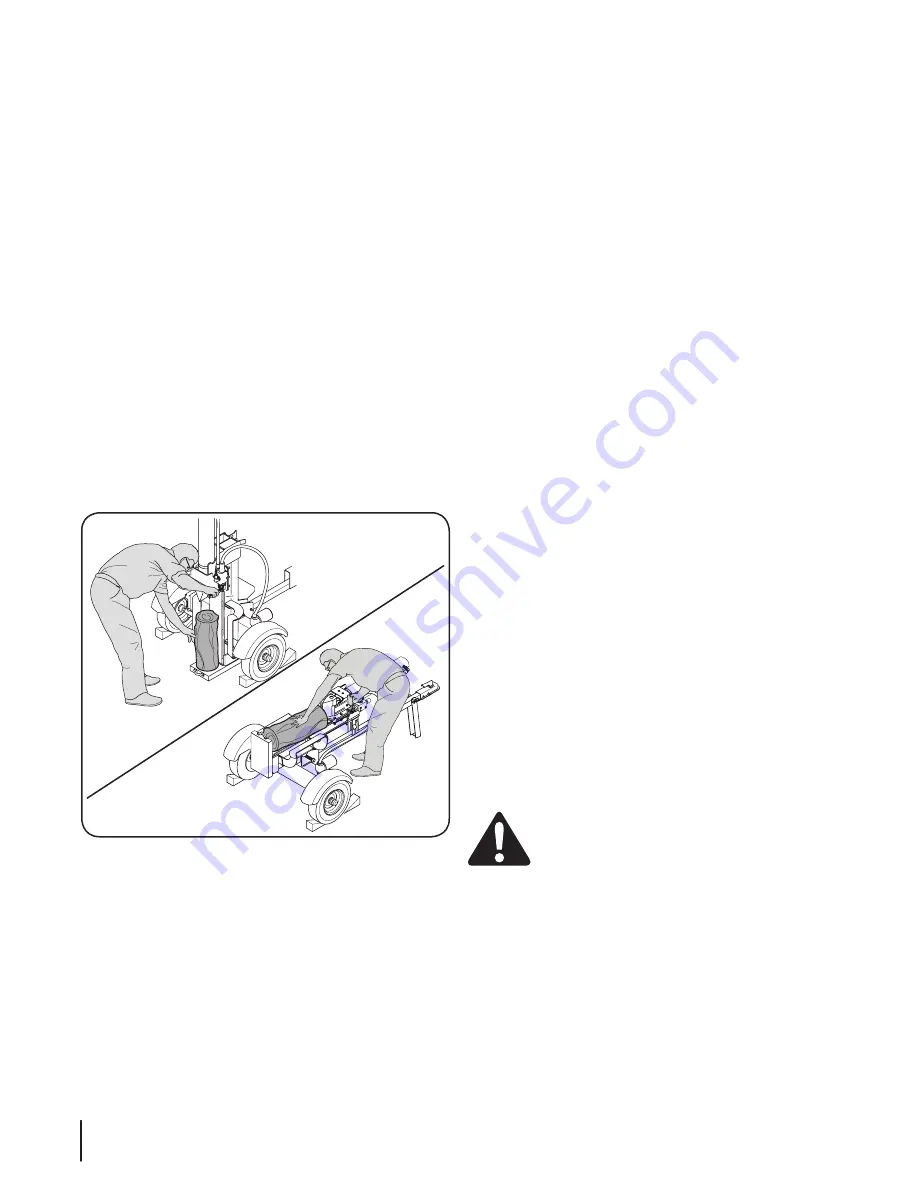

Always operate this machine from the operator zone(s)

specified in the manual. See Figure 2-1.

Horizontal

Vertical

Figure 2-1

7.

Logs should be cut with square ends prior to splitting.

8.

Use log splitter in daylight or under good artificial light.

Safe Handling of Gasoline

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine is

hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f.

Never overfill the fuel tank. Fill tank to no more than

1⁄2-inch below bottom of filler neck to provide space

for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment and move machine to another area. Wait

five (5) minutes before starting the engine.

i.

Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace, clothes

dryer or other gas appliances.

j.

Allow machine to cool at least five (5) minutes before

storing.

Operation

1.

Before starting this machine, review the “Safe Operation

Practices”. Failure to follow these rules may result in serious

injury to the operator or bystanders.

2.

Never leave this machine unattended with the engine

running.

3.

Do not operate machine while under the influence of

alcohol, drugs, or medication.

4.

Never allow anyone to operate this machine without

proper instruction.

5.

Always operate this machine with all safety equipment in

place and working. Make sure all controls are operating

properly for safe operation.

6.

Operator Zone

a.

Horizontal Operating Position: Stand on the control

lever side of the log splitter and stabilize log as

shown, if needed. See Figure 2-1.

b.

Vertical Operating Position: Stand in front of the log

splitter and stabilize log as shown, if needed. See

Figure 2-1.

WARNING!

When stabilizing log with left hand,

remove your hand when the wedge just contacts

the log or serious injury may occur.

7.

When loading a log, always place your hands on the side

of the log, not on the ends, and never use your foot to help

stabilize a log. Failure to do so, may result in crushed or

amputated fingers, toes, hand, or foot.

8.

Use only your right hand to operate the controls.

9.

Never attempt to split more than one log at a time.

10. For logs which are not cut square, the least square end of

the log should be placed toward the beam and wedge, and

the square end placed toward the end plate.

Summary of Contents for RM 33 LS

Page 22: ...Notes 10 22...

Page 23: ...23 Section 10 Notes...