8

S

ection

3— A

SSembly

& S

et

-U

p

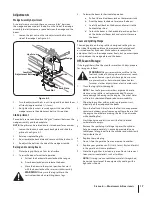

Attaching The Wheels To The Reservoir Tank Assembly

1.

Block up the reservoir tank assembly about eight to twelve

inches.

2.

Remove and discard the plastic shipping caps on the

outside of the wheels.

3.

Remove the cotter pin, slotted nut and flat washer from

each axle. See Figure 3-2.

Slotted Nut

Flat Washer

Cotter

Pin

Hub Cap

Figure 3-2

NOTE:

Wiping the axles with emery cloth before installing

the wheels is recommended.

4.

Place a wheel on each axle with the valve stem facing

outward.

5.

Place a flat washer on each axle and secure with a slotted

nut.

6.

Tighten the slotted nut until snug and then back off

approximately 1⁄3-turn or until one of the slots on the

slotted nut lines up with the hole in the axle.

7.

Insert the cotter pins through the slots in the nuts and

holes in the axle and secure the assembly by bending both

ends of the cotter pin out and then up against the end of

the axle as shown to provide clearance for the hub cap. See

inset Figure 3-2.

NOTE:

The wheels should spin freely and there should be

no side to side play.

8.

Place the hub caps in position on the wheels and tap onto

the axle with a rubber mallet. See Figure 3-2.

Attaching the Beam Support

1.

Remove the two hex bolts and lock nuts from the tongue.

2.

Place the beam support/latch bracket on the tongue

and secure it with the hex bolts and lock nuts previously

removed. Tighten Securely. See Figure 3-3.

Hex bolts

Lock Nuts

Figure 3-3

Jack Stand

The jack stand is shipped in the transport position.

1.

Remove the spring clip and clevis pin and pivot the jack

stand toward the ground to the operating position.

2.

Secure the jack stand in position with the clevis pin and the

spring clip. See Figure 3-4.

Clevis Pin

Spring Clip

Figure 3-4

Summary of Contents for RM 33 LS

Page 22: ...Notes 10 22...

Page 23: ...23 Section 10 Notes...