Operation

5

10

WARNING!

Read, understand, and follow all

instructions and warnings posted on the machine, in

this manual and in the separate engine manual

before operating.

WARNING!

Be sure no one other than the operator

is standing near the tiller while starting the engine

or operating the unit. Never run the engine indoors

or in enclosed, poorly ventilated areas. Engine

exhaust contains carbon monoxide, an odorless and

deadly gas. Keep hands, feet, hair and loose clothing

away from any moving parts on the engine and the

tiller.

Starting & Stopping the Engine

With the spark plug wire disconnected from the spark plug,

perform the following checks and services before each use:

1.

Check unit for loose or missing hardware. Service as

required.

2.

Check engine oil level. See the Engine Operator’s Manual.

3.

Check that all safety guards and covers are in place.

4.

Check air cleaner and engine cooling system. See the

Engine Operator’s Manual.

WARNING!

GASOLINE IS HIGHLY FLAMMABLE AND

ITS VAPORS ARE EXPLOSIVE. Follow the gasoline

safety rules in the Important Safe Operations

Practices section of this manual. Failure to follow

gasoline safety instructions can result in serious

personal injury and property damage.

5.

Fill the fuel tank with gasoline according to the directions

in the Engine Operator’s Manual. Follow all instructions and

safety rules carefully.

6.

Attach the spark plug wire to the spark plug.

WARNING!

Never run the engine indoors or in an

enclosed, poorly ventilated area. Engine exhaust

contains carbon monoxide, an odorless and deadly

gas. Avoid the engine muffler and nearby areas.

Temperatures in these areas may exceed 150° F.

7.

Release all of the controls on the tiller.

8.

Start and stop the engine as instructed in the Engine

Operator’s Manual

Using Your Tiller

Your tiller is designed for seed bed preparation, cultivating,

furrowing, and mulching.

Controlling Tilling and Depth Speed

By increasing the depth of the depth stake, the forward speed

of the machine is reduced and the working depth is increased.

When the depth stake is raised, the working depth of the

machine is reduced and the forward speed is increased.

The working depth of the machine may be predetermined by

setting the depth stake so that the wheels are about four inches

from the ground when the tines and depth stake are resting on

the ground. This setting will permit a working depth of about

four inches. When presetting the working depth, the handles

should be adjusted so the hand grips are a little above the waist.

The tiller will be lower when the tines and depth stake penetrate

the ground.

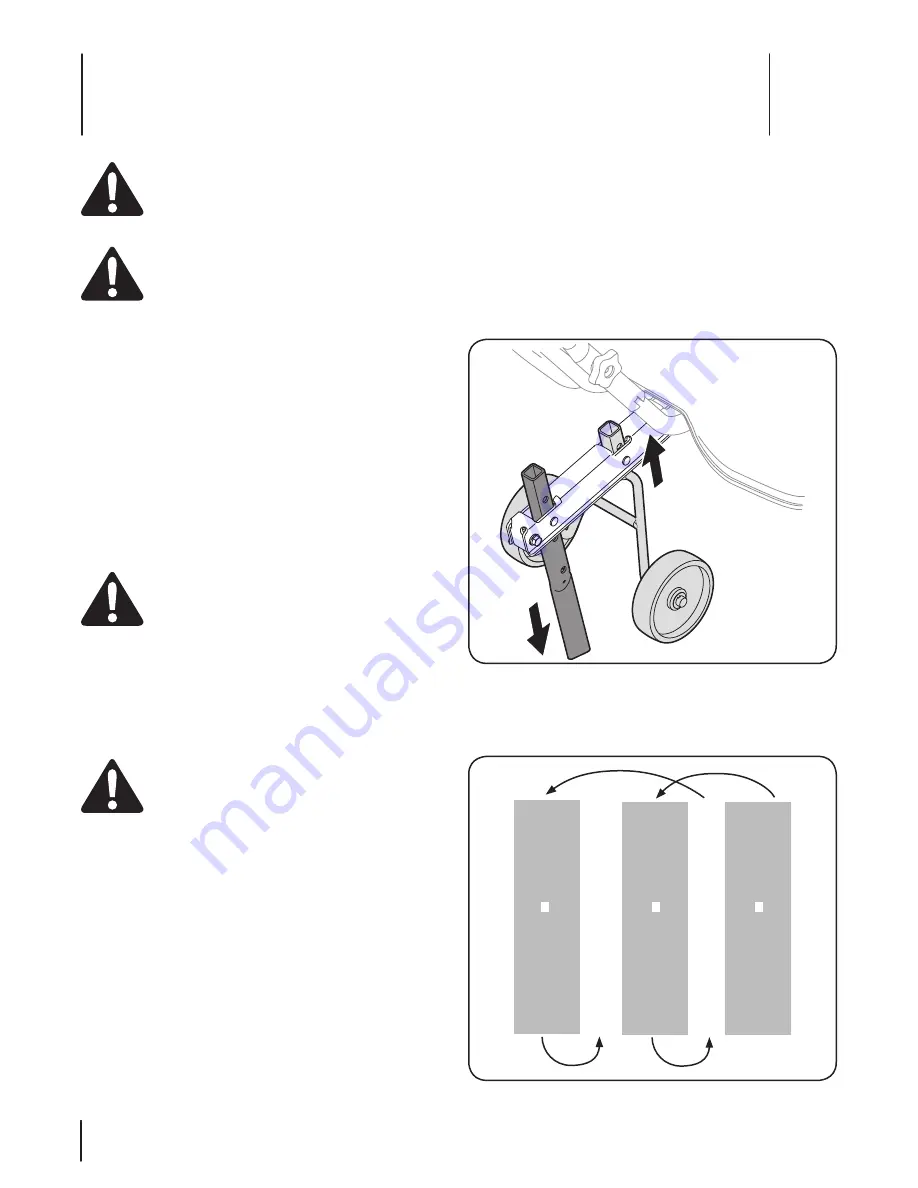

For tilling, the depth stake must be lowered and the wheels

must be raised. See Figure 6-1.

Figure 6-1

When tilling, leave approximately eight inches of untilled soil

between the first and second tilling paths, then make the third

path between the first and second. See Figure 6-2.

5

4

3

2

1

Figure 6-2