ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

14

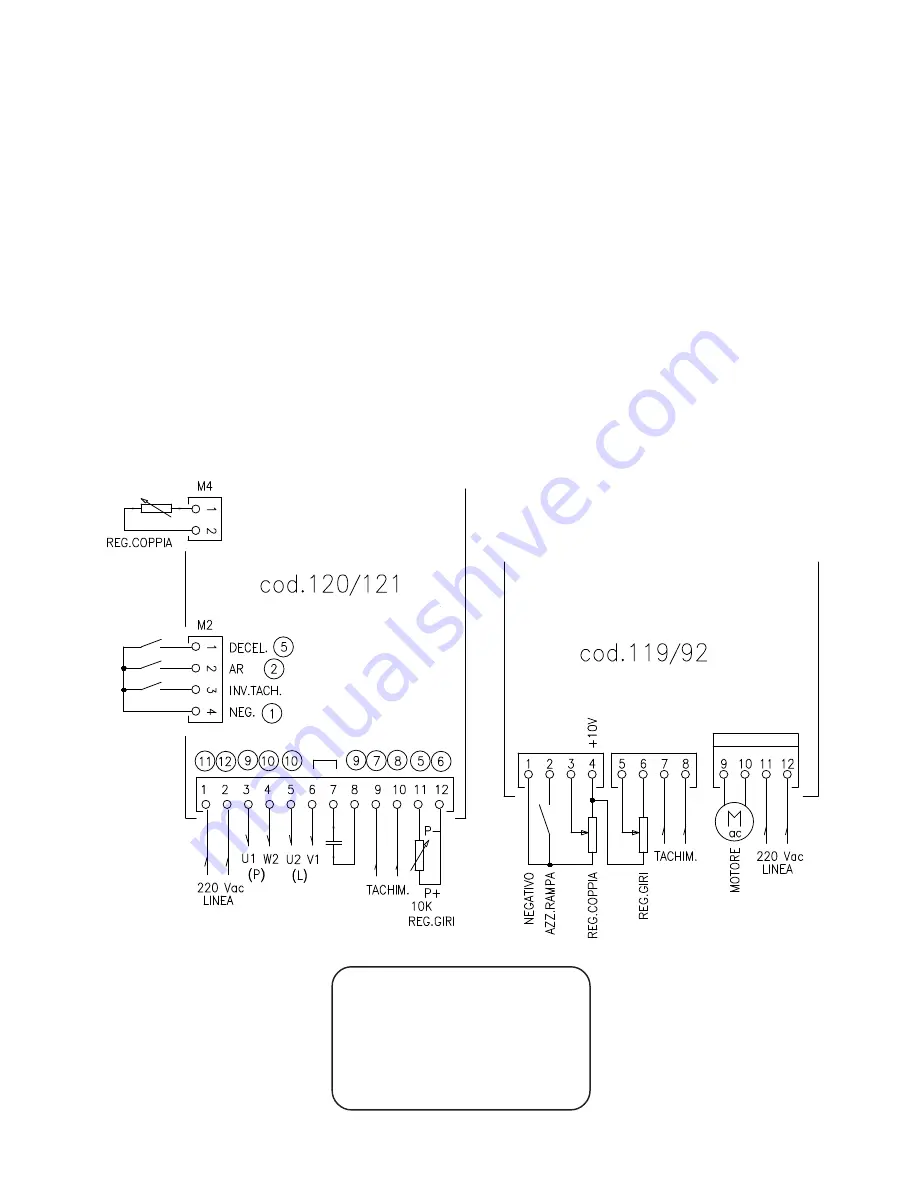

For the power connections proceed as follows:

the wires that were connected to the terminals 1 and 2 are to be shifted to terminals 11 and 12 of C119/92, whereas

the wires connected to terminals 3 4 5 6 7 8 related to the capacitor and power and launching windings are to be

reconnected together as shown in the schematic.

For the control connections proceed as follows:

the tachometer wires that were connected to terminals 9 and 10 are to be connected to terminals 7 and 8 of C119/92,

whereas the potentiometer wires as follows: P-(OV), connected to terminal 11, must be shifted to terminal 6,

whereas P+, connected to terminal 12, must be shifted to terminal 5 of C119/92.

For control wires connected to lateral terminal strip M2 of board C120/121 proceed as follows:

shift the wire connected to terminal NEG to terminal 1 of C119/92;

shift the wire connected to terminal AR to terminal 2 of C119/92;

exclude the wire connected to terminal INV. TACH. since it is unnecessary for C119/92;

connect wire connected to terminal DECEL to terminal 5 of C119/92.

Close microswitch S1 (for other microswitches refer to the paragraph describing the microswitches).

If a potentiometer is connected to terminal board M4 for torque limitation, you should reconnect it to terminals

1 3 4 of code 119/92 with 3 wires as illustrated in the schematic diagram; in this case close microswitch S2.

The circled numbers in the schematic refer to the terminals on C119/92.

Reg. Coppia = Torque Regulation

Reg. Giri = Speed Regulation

Tachim.= Tachometer Generator

Linea = Mains Line

Negativo = Negative

Azz. Rampa = Ramp to zero setting

Inv. Tach. = Tachometer Inversion

Decel = Deceleration

Replacing drive C120/121 with drive C119/92