ROWAN ELETTRONICA s.r.l. - Via Ugo foscolo, 20 - 36030 CALDOGNO (Vicenza)

page 11 out of 24

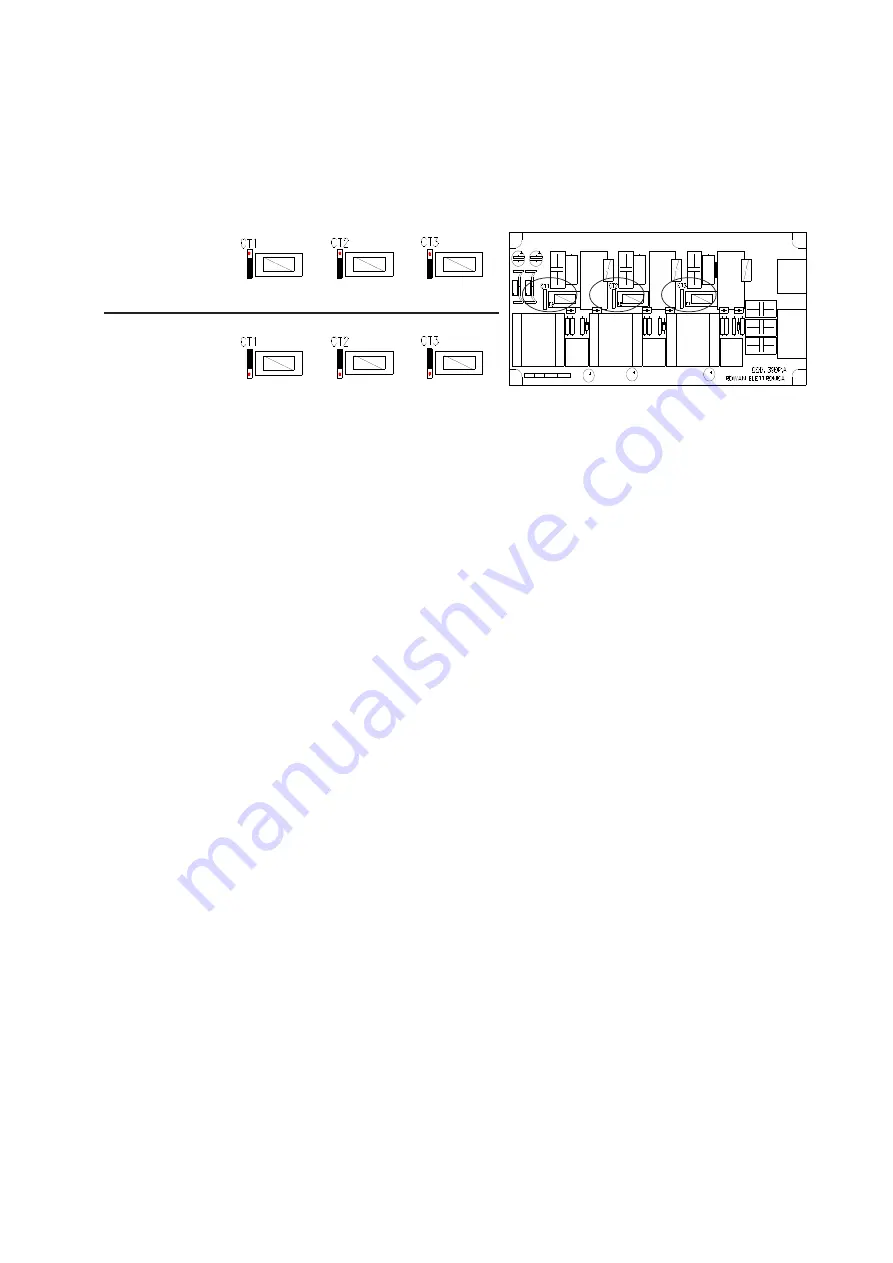

F1

F1

F3

F3

F2

F2

SETTING AT WORKS

PRELIMINARY OPERATIONS:

Before fixing the card, it is convenient to prepare the 3 adjusters according to the supply voltage. It should be kept in mind

that the card comes out of the Rowan laboratories set for the higher range of voltages. To reach the adjusters housed in the

lower card which goes to the power terminal board, the snap on terminals and then the silk screened cover should be

removed. The cover support columns should then be unscrewed, and the upper card which goes to the command terminal

board delicately overturned. The adjusters should be pre-set as follows:

Card pre-set for

1 7 0 V A C ÷ 2 6 0 V A C

supply field

Card pre-set for

3 3 0 V A C ÷ 5 0 0 V A C

supply field

F1 - F2 - F3 0.5 A fuses, controlling protection

The microswitches, trimmers and leds (their functions are explained on pages 6, 7 and 8) can be found on the

upper card, where the rest of the pre-settings are carried out.

To take the card to minimum basic operation (motor speed control from potentiometer), follow these instructions:

Pre-set the S3 micro according to the polarity of the motor to be adjusted

2 pole motor / S3 micro open

4 - 6 pole motor / S3 micro closed

In the case of 6 pole motors, it is further necessary to adjust the P4 trimmer in an anticlockwise direction until the tachimetric

generator produces approx. 5.7 VDC with the potentiometer or DC signal at maximum.

Choose the acceleration and deceleration ramp range:

S2 micro open

P1 trimmer adjustment field (deceleration), minimum 0.02 sec. - max. 2 sec.

P2 trimmer adjustment field (acceleration), minimum 0.02 sec. - max. 2 sec.

S2 micro closed

P1 trimmer adjustment field (deceleration), minimum 0.25 sec. - max. 25 sec.

P2 trimmer adjustment field (acceleration), minimum 0.25 sec. - max. 25 sec.

Connect RUN and STOP IN RAMP as shown in the main connecting diagram on page 4; keep in mind that the two contacts

must be closed to let the motor turn.

Connect the speed adjusting potentiometer (optimal value 10K) to 3 wires of terminals 3 - 6 - 7, open the S1 micro and

close S12; when cursor 6 is towards terminal 7 (6 - 7=0VDC) the motor is stationary; when cursor 6 is towards terminal 3

(6 - 7= -10VDC) the motor turns at maximum speed.

Set the remaining microswitches as follows: S5-S6-S8-S12 closed and S4-S7-S9-S10-S11 open.

Connect the motor card according to the instructions given on pages 8 and 9:

Star or triangle connect according to the line and the motor plate details; earth the motor.

The tachimetric generator signal, which should be connected to terminals 1-2 of the 390S card, should be taken from

terminals 1-2 of the motor terminal board.

The cooling fan supply (230VAC - 50/60Hz) should be taken to terminals 3-4 of the motor terminal board and the motor fan

should not be connected to the motor operation but to the control panel operation. By doing this it is possible to cool the

motor even during rest periods; in motors with threephase cochlear fans connection is carried out directly on the fan base.

The thermal sensor is connected to terminals 5-6 of the motor terminal board. It is a normally closed contact (1A-230VAC),

which should be applied in series to the emergencies - in fact it is inserted directly onto the motor windings and opens if the

temperature reaches the safety limit for tropicalised windings in class H (150°C).

TO MAKE THE MOTOR ROTATE

Adjust the potentiometer so that the cursor connected to terminal 6 is in short with terminal 7.

Supply the card, the motor should be motionless.

The lit L1 (power on) pilot light indicates the presence of supply at the controlling circuits. The L6 running pilot lights up

to indicate that the motor can turn.

Turn the potentiometer. The motor should follow the increase or decrease adjustment with the acceleration and deceleration

ramps set. Verify that the maximum speed is reached, eventually retouch maximum calibration with the P3 trimmer

(MAXIMUM REVS.). Be careful not to exceed the maximum adjustment as this would send the motor into overabsorption,