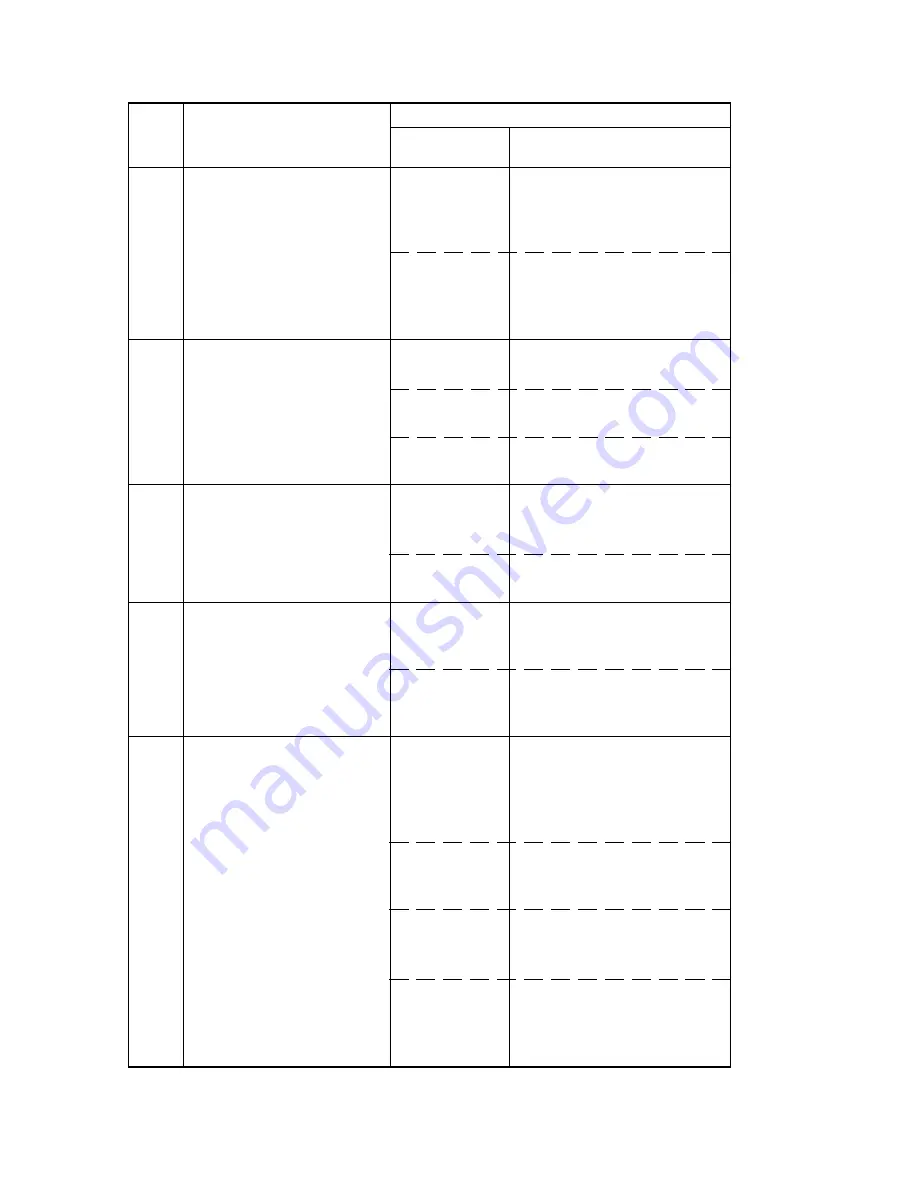

2A3/4

3-5-12

Defective

power source

PCB.

Defective en-

gine PCB.

Defective laser

diode.

Defective poly-

gon motor.

Defective main

PCB.

Defective high-

voltage trans-

former PCB.

Leakage during

main charging.

Defective high-

voltage trans-

former PCB.

Leakage during

transfer/sepa-

ration charging.

Poor contact of

the fixing unit

thermistor con-

nector termi-

nals.

Broken fixing

unit thermistor

wire.

Fixing unit ther-

mistor installed

incorrectly.

Fixing unit ther-

mostat

triggered.

Check if 24 V DC is supplied

to CN6-5 on the engine PCB.

If not, replace the power

source PCB.

Check if 24 V DC is output

from CN7-1 on the engine

PCB. If not, replace the engine

PCB.

Replace the LSU.

Replace the LSU.

Replace the main PCB.

Replace the high-voltage

transformer PCB.

Check and clean the main

charger assembly.

Replace the high-voltage

transformer PCB.

Check and clean the transfer

charger assembly.

Check the connection of con-

nector CN3-B8 on the engine

PCB and the continuity across

the connector terminals. Re-

pair or replace if necessary.

Measure the resistance. If it is

infinite, replace the fixing unit

thermistor.

Check and reinstall if neces-

sary.

Check for continuity. If none,

replace the fixing unit thermo-

stat.

C401

C420

C510

C511

C610

Polygon motor steady-

state problem

• The polygon motor rotation

is not stable for 600 ms af-

ter the polygon motor rota-

tion has been stabilized.

BD steady-state problem

• The VTC detects a BD er-

ror for 600 ms after the

polygon motor rotation has

been stabilized.

Main charger problem

• MC ALM signal is detected

continuously for 400 ms

when MC REM signal is

turned on.

Transfer/separation high-

voltage problem

• STALM signal is detected

continuously for 400 ms

when TC/SC REM signal is

turned on.

Broken fixing unit ther-

mistor wire

• The fixing temperature

does not increase for 40 s

after the fixing heaters

have been turned on for

warming up.

• The fixing temperature re-

mains below 50˚C/122˚F

for 10 s continuously after

the fixing heaters have

been turned on during sta-

bilization.

Code

Contents

Remarks

Causes

Check procedures/

corrective measures

Summary of Contents for Ri 4230

Page 3: ...SERVICE MANUAL Ri 4230 5230 ...

Page 13: ...4230 5230 S M MCA THEORY AND CONSTRUCTION SECTION I I Theory and Construction Section ...

Page 14: ...1 1 5 2A3 4 CONTENTS 1 1 Specifications 1 1 1 Specifications 1 1 1 ...

Page 100: ...4230 5230 S M MCA ELECTRICAL SECTION II II Electrical Section ...

Page 119: ......

Page 138: ......

Page 159: ...4230 5230 S M MCA III Set Up and Adjustment Section III SET UP AND ADJUSTMENT SECTION ...

Page 448: ...2A3 4 3 6 3 25 Toner scatters at the leading edge of the image See page 3 6 17 ...