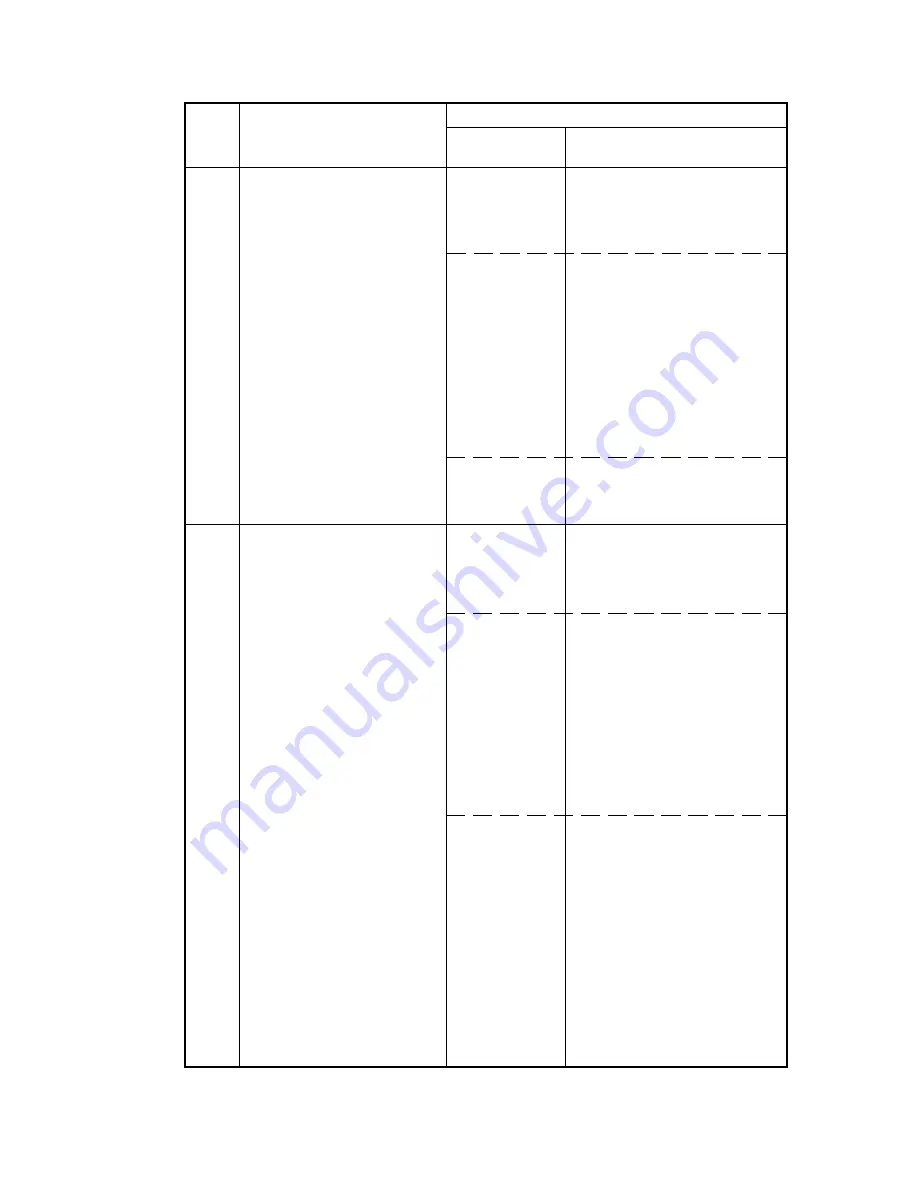

2A3/4

3-5-19

The front sta-

pler connector

makes poor

contact.

The front sta-

pler malfunc-

tions.

a) The front

stapler is

blocked with a

staple.

b) The front

stapler is bro-

ken.

Defective fin-

isher main

PCB.

The rear sta-

pler connector

makes poor

contact.

The rear sta-

pler malfunc-

tions.

a) The rear sta-

pler is blocked

with a staple.

b) The rear sta-

pler is broken.

Defective fin-

isher main

PCB.

Reinsert the connector. Also

check for continuity within the

connector cable. If none, rem-

edy or replace the cable.

a) Remove the front stapler

cartridge, and check the car-

tridge and the stapling section

of the stapler.

b) Replace the front stapler

and check for correct opera-

tion.

Replace the finisher main PCB

and check for correct opera-

tion.

Reinsert the connector. Also

check for continuity within the

connector cable. If none, rem-

edy or replace the cable.

a) Remove the rear stapler

cartridge, and check the car-

tridge and the stapling section

of the stapler.

b) Replace the rear stapler

and check for correct opera-

tion.

Replace the finisher main PCB

and check for correct opera-

tion.

C821

C822

Finisher front stapler

problem*

2

• The front stapler home po-

sition sensor does not

change state from non-de-

tection to detection within

0.2 s of the start of front

stapler motor counterclock-

wise (forward) rotation.

• During initialization, the

front stapler home position

sensor does not change

state from non-detection to

detection within 0.6 s of the

start of front stapler motor

clockwise (reverse) rota-

tion.

Finisher rear stapler prob-

lem*

2

• The rear stapler home po-

sition sensor does not

change state from non-de-

tection to detection within

0.2 s of the start of rear

stapler motor counterclock-

wise (forward) rotation.

• During initialization, the

rear stapler home position

sensor does not change

state from non-detection to

detection within 0.6 s of the

start of rear stapler motor

clockwise (reverse) rota-

tion.

Code

Contents

Remarks

Causes

Check procedures/

corrective measures

*2: optional.

Summary of Contents for Ri 4230

Page 3: ...SERVICE MANUAL Ri 4230 5230 ...

Page 13: ...4230 5230 S M MCA THEORY AND CONSTRUCTION SECTION I I Theory and Construction Section ...

Page 14: ...1 1 5 2A3 4 CONTENTS 1 1 Specifications 1 1 1 Specifications 1 1 1 ...

Page 100: ...4230 5230 S M MCA ELECTRICAL SECTION II II Electrical Section ...

Page 119: ......

Page 138: ......

Page 159: ...4230 5230 S M MCA III Set Up and Adjustment Section III SET UP AND ADJUSTMENT SECTION ...

Page 448: ...2A3 4 3 6 3 25 Toner scatters at the leading edge of the image See page 3 6 17 ...