INSTALLATION REGULATIONS AND REQUIREMENTS

In the interests of both the Law and of Safety, this appliance must only be installed by a competent person in

accordance with the current Gas Safety (Installation and Use) Regulations or the rules in force and the

manufacturer’s instructions. Note: Failure to install a gas appliance correctly could lead to prosecution.

The following are the relevant Codes of Practice and British Standards.

The Building Regulations issued by the Department of the Environment.

The Building Standards (Scotland)(Consolidation) Regulations issued by the Scottish Development Department.

BS 83O3 1986

BS 544O Pt1 199O

BS 544O Pt2 1989

BS 1251 1987

BS 5871 Pt2 1991

BS 7566 Pt 1-4 1992

BS 6891 1988

BS 6461 Pt1 1984

BS 715 1993

BS 1289 Pt1 1986 & 1975

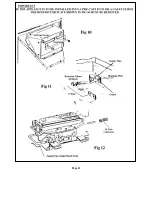

FIRE SURROUND AND OPENING REQUIREMENTS

Check that the chimney and flue structure are sound and conform to the following flue requirements:

a) A conventional brick or stone chimney with a minimum effective cross-sectional dimension of 228mm x

228mm, a lined flue with a minimum diameter of 175mm, a minimum effective height of 3m and having a

chairbrick and throat forming lintel conforming to BS 1251 or a builders opening measuring 540mm high x 400mm

wide with a sufficient volume for debris collection. If a chairbrick is fitted, a minimum depth requirement for the

fire with the spacer fitted is shown in fig 1 - if insufficient space is available the chairbrick will have to be removed.

b) A twin walled metal flue box manufactured to BS 715 with a 125mm diameter insulated flue with a minimum

effective height of 3 metres. See page 6.

c) A pre-cast flue conforming to the requirements of BS 1289 Pt 1 1986 including properly constructed pre-cast

flues (formerly BS 1289 1975) with a cross sectional area of 13000sq mm.

Dampers, register plates or incorrect flue terminals, must not restrict any of the above flues. The flue must only

service a single appliance and not have any branches or traps which may impede the natural draught, any flue

damper or restrictor must be removed or fixed in the fully open position.

The front and base of the fire opening must be flat and square to ensure a good seal with the appliance; this is to

ensure that there is no reduction in draught that may cause spillage to occur.

CONTENTS CHECK LIST

Fire Box Assembly c/w

Fixing Kit

Burner Assembly

6 Plastic Wall Plugs

Glass Panel

4 No 10 x 1 1/4" Round Hd Woodscrews

Flue Restrictor

4 U-Spring Clips

Blanking Plate & Gasket

2 No 8 x 1" Round Hd Woodscrews

2 No 8 x 1/2" Self Tap Screws

Ceramic Components

2 Penny Washers

Fibre Back panel

4 M4 x 12 Pan Hd Machine Screws

L & R Hand Side Cheeks

1 8mm Equal End Coupling

Simulated Coal front

2 M4 Wing Screws

Coal Support Shelf

1 Cable Fixing Kit

10 Large Coals

Bundy Pipe for Concealed Fitting

3 Small Coals

Bundy Pipe for RH Gas Supply

8mm x 8mm Inline Connector

Components

Installation & Servicing Instructions

Fender

Users Instructions

Ash Pan Cover

Brass Knob Kit

L & R Hand Side Covers

Canopy

Spacer Frame

Page 3

Summary of Contents for U19019 G20

Page 12: ...Page 5 ...

Page 16: ...Page 8 ...

Page 17: ...Page 9 ...

Page 18: ...Page 10 ...

Page 19: ...Page 11 ...

Page 20: ...Page 12 ...

Page 23: ...Page 15 ...