INSTALLATION OF THE APPLIANCE

Check that the chimney conforms to the required specifications as previously stated. Examine the condition and

carry out any remedial work, if the flue has been used for solid fuel it should be swept and a smoke test carried out

to check that satisfactory smoke clearance has been established. If all the smoke is not drawn into the flue, pre-heat

the flue with a blowtorch or similar and re-check. If there is any uncertainty examine for the cause and if necessary

seek expert advice.

GAS SUPPLY

BEFORE COMMENCING WORK TURN OFF ANY APPLIANCES THAT ARE FED BY THE METER

AND ISOLATE THE GAS SUPPLY BY TURNING OFF AT THE METER

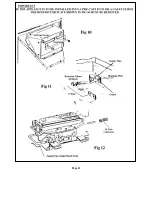

The gas connection to this appliance is made with 8mm o/d rigid or semi-rigid tube to a pressure test elbow situated

on the L/H side of the burner as shown in fig 14. It is advisable to provide a means of isolating the gas supply to the

appliance for servicing with either a restrictor elbow or isolation cock such as shown in fig 18. Provision is made

for the gas supply to enter in the rear left corner, using a blanking plate and gasket, to enable a seal to be made

around the tube see fig 11. Any tube used under the burner must be rigid or semi-rigid tube such as bundy, formed

sections are provided which may be used to connect to 8mm copper using the inline connector supplied. Copper

tube must not be used under the burner to avoid exceeding the maximum 100

o

C temperature permissible for

copper tube. Alternately the supply may be routed from either the left or right hand side of the appliance as shown in

fig 12.

Where a connection is to be made direct to the control valve, the support pipe bracket can be removed by

unscrewing the control mounting lock nut and sliding the bracket over the control spindle and re-tightening the lock

nut.

Where a concealed gas supply is used, the installer is reminded of the requirements of BS 6891 1988 dealing with

enclosed pipes. The Standard requires that when a gas pipe is fed through a wall, the pipe should be enclosed in a

tight sleeve to protect against failure caused by movement and shall be constructed to prevent passage of gas either

between the pipe and sleeve or sleeve and wall.

DISMANTLING THE APPLIANCE PRIOR TO INSTALLATION

Carefully remove the front glass panel, held in position with 4 x winged thumbscrews and a retaining strip. Ensure

care is taken to support the glass panel while removing the screws and then lift the glass panel clear of the retaining

brackets in the bottom L&R hand corners.

In most instances it will be necessary to remove the burner to gain access for a concealed gas supply. Remove the

two screws securing the burner in position, lift and pull the burner assembly forward observing the two tags locating

the rear legs in position. If a concealed gas supply is to be used remove the blanking plate and gasket from the rear L

hand corner.

INSTALLING THE APPLIANCE IN POSITION

When the gas supply pipe has been laid in the required position and the surround and hearth has been fitted correctly

and sealed to the chimney to prevent seepage of flue products from the flue, precautions should be taken to protect

any polished surfaces from scratches or damage. The installation should be checked for gas soundness prior to

fitting the appliance.

Two options are provided that should enable the appliance to be secured in position, both of these require that every

precaution be taken to ensure that a good seal exists between the appliance and the flue.

OPTION a)

Is to secure the appliance to the back panel/surround through the 4 holes provided around the rear frame of the

appliance.

a (i)

If a spacer frame is not required, remove either the screws and captive nuts blanking off the fixing holes or, remove

the (semi-sheared) knock-out holes, dependant on manufacturing methods used. Place the fire in the required

position, spot and drill through the fixing holes for the plastic fixing plugs supplied and secure in place in the

positions shown in fig 6.

Summary of Contents for U19019 G20

Page 12: ...Page 5 ...

Page 16: ...Page 8 ...

Page 17: ...Page 9 ...

Page 18: ...Page 10 ...

Page 19: ...Page 11 ...

Page 20: ...Page 12 ...

Page 23: ...Page 15 ...