ROYAL ENFIELD WORKSHOP MANUAL

PAGE 70

6. Hub Bearings

These are deep-groove single-row journal ball

bearings,

5

/

8

in. i/d by 1.

9

/

16

in. o/d by

7

/

16

in.

wide. The Skefko Part No. is RLS5. Equivalent

bearings of other makes are Hoffmann LS7,

Ransome and Marles LJ

5

/

8

in., Fischer LS7.

7. Fitting Limits for Bearings

The fit of the bearings in the hub barrel is

important. The bearings are locked on the spindle

between shoulders and the distance pieces, which

in turn are held up by the nuts on the spindle. In

order to prevent endways preloading of the

bearings it is essential that there is a small

clearance between the inner edge of the outer race

of the bearing and the back of the recess in either

end of the barrel. To prevent any possibility of

sideways movement of the hub barrel on the

bearings it is, therefore, necessary for the bearings

to be a tight fit in the barrel, but this fit must not

be so tight as to close down the outer race of the

bearing, and thus overload the balls. The

following are the manufacturing tolerances which

control the fit of the bearings. The figures for the

bearings themselves are for SKF. bearings, but

other manufacturers' tolerances are similar.

Bearing o/d, 1.5622/1.5617 in.

Housing bore, 1.5620/1.5616 in.

Bearing bore, .6252/.6247 in.

Shaft diameter, .6252/.6248 in.

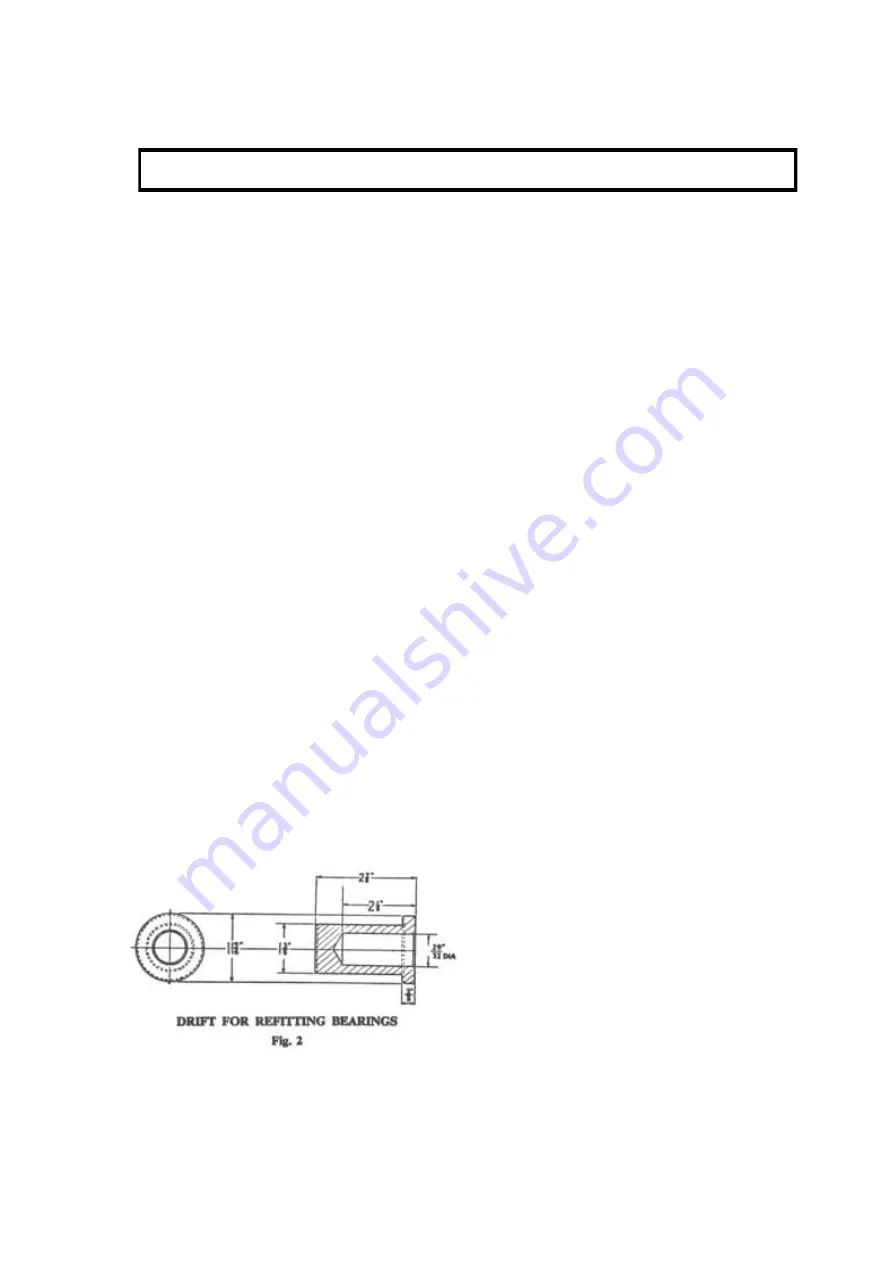

8. Refitting Ball Bearings

To refit the bearings in the hub, two hollow

drifts are required, as shown in Fig. 2. One bearing

is first fitted to one end of the spindle by means of

the hollow drift ; the spindle and bearing are then

entered into one end of the hub barrel, which is

then supported on one of the hollow drifts. The

other bearing is then threaded over the upper end

of the spindle and driven home by means of the

second hollow drift either under a press, or by

means of a hammer, which will thus drive both

bearings into position simultaneously.

In order to make quite sure that there is clearance

between the inner faces of the outer bearing races

and the bottom of the recesses, fit the distance

washers, cover plate, dust excluder and the nuts

on the spindle. Tightening the nuts should not

have any effect on the ease with which the spindle

can be turned. If tightening the nuts makes the

spindle hard to turn this may be taken as proof

that the bearings are bottoming in the recesses in

the hub barrel before they are solid against the

shoulders on the spindle. In this case, the bearing

should be removed and a thin packing shim fitted

between the inner race and the shoulder on the

spindle.

9. Re-assembly of Brake Shoes and Operating

Cam into Cover Plate

No difficulty should be experienced in carrying

out these operations. Put a smear of grease on the

pivot pin and on the operating face of the cam ;

also on to the cylindrical bearing surface of the

operating cam. Fit the operating lever on its

splines in a position to suit the extent of wear on

the linings and secure with the nut and washer.

Note that the position of the operating lever may

have to be corrected when adjusting the brake

after refitting the wheel. The range of adjustment

can be extended by moving this lever on to a

different spline. Limit of wear is reached when the

cam is turned through nearly 90° with the brake

hard on, so that there is a danger that the

operating springs cannot return the brake to the

off position.

10. Final Assembly of Hub before Replacing

Wheel

Before replacing the felt washers which form

the grease seals, pack all bearings with grease.

Recommended greases are Castrolease LM,

Mobilgrease MP, Esso Multipurpose Grease H,

Energrease L2, Shell Retinax A, or Marfak

Multipurpose 2. The use of H.M.P. greases which

have a soda soap base is not recommended, as

these tend to be slightly corrosive if any damp

finds its way into the hubs.

Make sure that the inside of the brake drum is

quite free from oil or grease, damp, etc. Replace

the felt washers, distance collars, dust excluder and

brake cover plate and securely tighten the spindle

nuts.

11. Wheel Rim

The wheel rim is WM2-17 in. plunged and

pierced with forty holes for spoke nipples. The

spoke holes are symmetrical, i.e., the rim can be

assembled to the hub either way round. The rim

diameter after building is 17.062 in., the tolerance

K4

www.hitchcocksmotorcycles.com

Summary of Contents for 250 CLIPPER

Page 40: ...ROYAL ENFIELD WORKSHOP MANUAL PAGE 40 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 46: ...ROYAL ENFIELD WORKSHOP MANUAL PAGE 46 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 52: ...ROYAL ENFIELD WORKSHOP MANUAL PAGE 52 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 62: ...ROYAL ENFIELD WORKSHOP MANUAL PAGE 62 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 72: ...ROYAL ENFIELD WORKSHOP MANUAL PAGE 72 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 76: ...ROYAL ENFIELD WORKSHOP MANUAL PAGE 76 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 88: ...ROYAL ENFIELD WORKSHOP MANUAL PAGE 88 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...