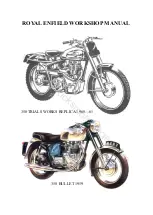

ROYAL ENFIELD WORKSHOP MANUAL

Section C14 Page 8

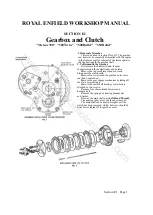

retaining ring and the assembly of driving and

driven clutch plates. The clutch sprocket can then

be withdrawn from the centre after removal of

the large circlip which secures it.

21. Removal of the Tappets and Guides

It is only necessary to remove the tappets and

guides if they have become worn.

To remove the guides use Special Tool No.

E.5410.

The guide should have an interference fit of

.0015 in. to .0025 in. in the crankcase and can be

driven in with a bronze drift, care being taken

when the guide is nearly home to avoid damaging

the collar. Excessive hammering may close up the

bore of the guide which would necessitate

removing the tappet and reaming again. In no

circumstances should the guide be reamed in

position on the 350 c.c. engine as swarf might get

into the recess in the guide.

22. Dismantling the Breather

If the breather is not operating efficiently, it

may cause pressure in the crankcase, instead of a

partial vacuum, giving rise to smoking or

overoiling. If the breather is of the disc type, see

that the discs and backplate are clean and

undamaged and that the discs are seating

properly.

When reassembling the breather, apply

jointing compound very sparingly to the back of

the steel plate taking great care to keep it away

from the discs or their seatings.

If the breather is of rubber tube type, there

are no moving parts and it is only necessary to

see that the tube is not damaged or distorted.

If the breather body is detached from the

driving side crankcase by removing the three

screws, see that the faces are clean when refitting

and apply jointing compound to ensure that the

seal is airtight.

23. Removal of the Clutch

Remove the engine sprocket and clutch

sprocket together as described in Subsection 20.

To remove the clutch centre, hold the clutch

with Special Tool No. E.4871, and remove the

centre retaining nut and washer with a box

spanner.

The clutch centre can then be withdrawn from

the shaft with Special Tool No. E.5414.

If the circlip is not removed the sprocket and

clutch centre can be removed together.

24. Removal of the Final Drive sprocket

Remove the clutch as described in Subsection

23.

Remove the primary chain tensioner

Remove the rear half of the primary chaincase

by taking out three socket screws.

Remove the grub screw locking the final drive

sprocket nut.

Hold the sprocket and remove the nut (right

hand thread) The sprocket can then be

withdrawn.

25 Pressure Relief Valve

There are two pressure feeds to the big end

and to the rocker gear respectively. Their function

is to prevent excessive pressure and their setting is

not critical. The feed to the rocker gear comes

from the return oil from the crankcase to the tank.

The pressure relief valves are set before leaving

the Works and should not normally require to

disturbed. If, however, it is found necessary to

dismantle either of them, they can be reset as

follows.

Rocker Feed Relief Valve. This is located on

the outside of the crankcase immediately below

the lower end of the external oil pipe. It has a

hexagon head and can be removed complete by

unscrewing it out of the case.

The valve itself cannot be dismantled and if

found to be faulty, should be replaced by a new

one.

Big End Relief Valve. This is located in the

timingside crankshaft and can only be adjusted

when the crankshaft has been dismantled. It

consists of a 5/16 in. diameter steel ball and spring

held in position by a screwed plug.

The valve is set to open when the oil pressure

exceeds about 35 lb. per square inch and when set

correctly there is a movement of about 3/32 in. of

the ball off the seat. This can be measured without

dismantling the crankshaft by pushing a thin rod

through the hole in the pump worm with the oil

feed plug in the timing cover removed.

If the crankshaft is dismantled for any reason,

it is always advisable to fit a new spring to the

relief valve in case the original one has become

weak.

If the valve is set to give too high a

pressure, the pump disc will be forced off its

seating.

26. Removal of the Magneto or Contact

Breaker Unit

The magneto of all but "Works Replica models”

also the contact breaker unit fitted to the "350

Clipper" and later "Bullets," is removed taking off

the timing cover (Subsection 1) and the driving

pinion (Sub-section 18), behind which are located

three screws which secure the spigotted magneto or

contact breaker unit

www.hitchcocksmotorcycles.com

Summary of Contents for 350 BULLET 1956

Page 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...