ROYAL ENFIELD WORKSHOP MANUAL

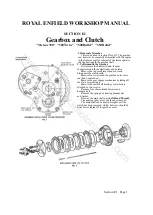

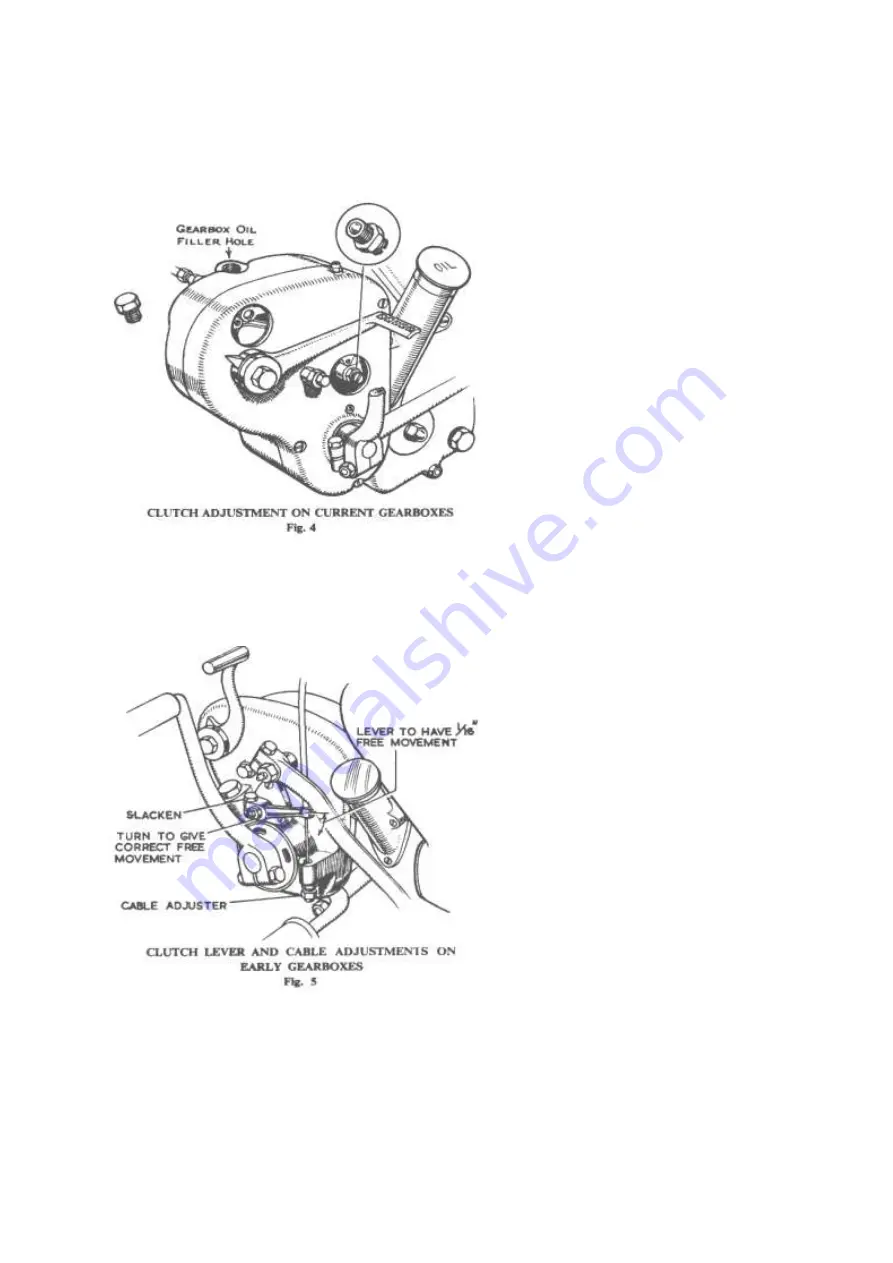

The other point of adjustment is behind the

lower inspection cover on the front of the gearbox

and is for compensating for wear on the clutch

plate inserts. To make the adjustment, remove the

inspection cover, slacken the locknut and turn the

central screw. Tighten the locknut after adjustment

has been made.

The reason for the two points of adjustment is

to enable the lever behind the cover to be kept in

its proper position whether the need for

adjustment is caused by plate wear or cable stretch.

Owing to initial bedding down of the clutch

plate inserts, the clutch control may require

adjustment after the first few hundred miles with a

new machine. This point should therefore be

examined soon after delivery and adjustment made

if necessary.

On earlier models the clutch operating

mechanism is exposed on the front of the gearbox,

but the adjustments are, however, the same in

principle as those described above.

The cable adjustment is at the bottom of the

front of the gearbox just in front of the kickstart

lever. The collar is screwed in or out of a lug on

the gearbox cover and is secured by a locknut as

before.

The other adjustment is made by slackening the

clamping bolt in the horizontal lever and turning

the lever on its spindle, which is the end of the

operating worm in the gearbox cover.

When correctly adjusted, the lever should be

approximately square with the cable when the

clutch is fully lifted.

The position of the lever endwise on the worm

spindle is important and it should be positioned so

that it does not foul the kickstart lever.

8. Adjustment of the Neutral Finder

The neutral finder is adjusted by means of an

eccentric stop secured to the front of the gearbox

cover by a bolt which limits the travel of the

operating pedal. Slacken the bolt and turn the

eccentric until the correct movement of the pedal is

obtained.

9. Gearbox Oil Level

The gearbox is replenished with oil by removing

a plug in the top and the correct level can be

checked by removing a second plug lower down on

the right hand side looking at the cover.

On earlier models a dip-stick is attached to the

filler plug for measuring the level of the oil or was

provided loose in the tool kit.

On some models the filler plug is on the side of

the gearbox and in such cases the oil should be

level with the plug hole and no dip-stick is required.

The oil will be found to run into the box more

easily on these models if the engine is started up

and allowed to tick over so that the gears and shafts

rotate.

Section E1 Page 4

www.hitchcocksmotorcycles.com

Summary of Contents for 350 BULLET 1956

Page 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...