ROYAL ENFIELD WORKSHOP MANUAL

Section G2k Page 3

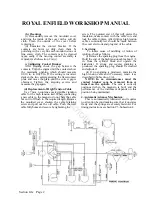

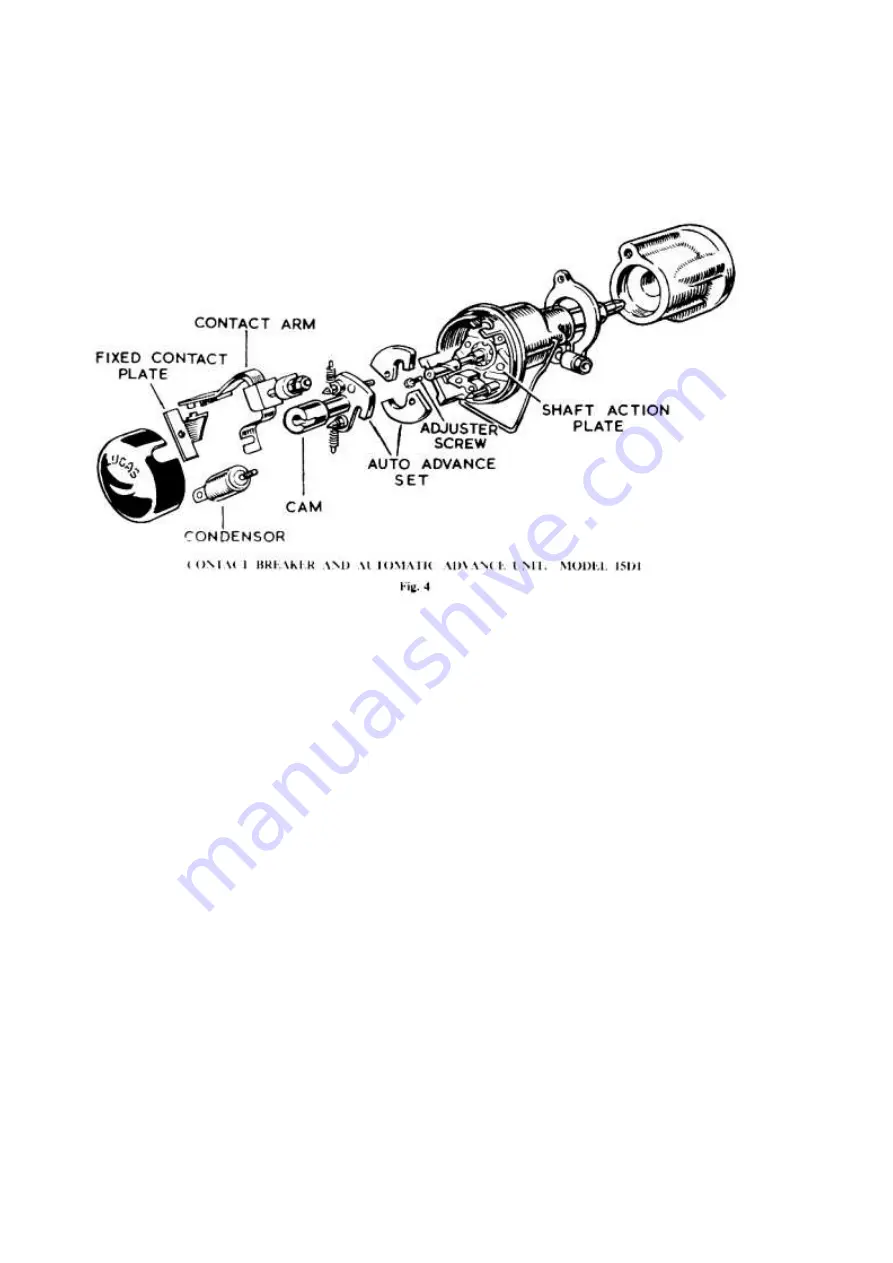

8. Contact Breaker Unit

Early Models: Type CA1A

Later Models: Type 15D1

Lubrication every 3,000 miles. No grease or

oil must be allowed to get on or near the contacts

when carrying out the following procedure.

Smear the surface of the cam very lightly with

Mobilgrease No. 2 non-creep oil or clean engine

oil.

Place a spot of Ragosine oil or clean engine

oil on the contact breaker pivot of type CA1A.

Contact Breaker Setting. The contact

breaker setting should be checked after the first

500 mile, running and subsequently every 6,000

miles. To check the gap, turn the engine over

slowly until the contacts are seen to be fully open

and insert a 0014-0016 in. feeler gauge between

the contacts.

If the gap width is correct the gauge will be a

sliding fit. To adjust the setting, set the engine in

the position giving maximum contact opening.

Slacken the two screws securing the fixed contact

plate fitted to early models, and the single screw in

the case of later models. Adjust tile position of the

plate until the gap is the thickness of the gauge,

and tighten.

Automatic Timing Control

Early Models. Every 3,000 miles remove the

central fixing bolt and inject a small amount of

clean engine oil into the hole thus exposed. When

the fixing bolt has been replaced and the engine

run for a few minutes, the oil will be forced out

over the automatic advance mechanism by

centrifugal force.

To expose the automatic timing mechanism

remove the two screws in the slotted holes of the

C/B base plate.

Later Models. Remove the contact breaker

cover and use clean engine oil to lubricate the

automatic timing mechanism in the base of the

unit. To obtain access, remove the contact

breaker arm, contact plate, condenser and the

screw in the end of the cam. The unit may then

be lifted out.

Cleaning every 6,000 miles. Examine the

contact breaker; the contacts must be free from

grease or oil. If they are burnt or blackened, clean

with fine carborundum stone or very fine emery

cloth, afterwards wiping away any trace of dirt or

metal dust with a clean petrol moistened cloth.

Cleaning of the contacts is made easier if the lever

carrying the moving contact is removed.

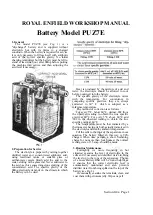

9. Renewing High Tension Cables

If any of the high-tension cables show signs

of perishing or cracking they must be replaced,

using 7mm. neoprene-covered rubber ignition

cable. To connect the cable to the distributor or

ignition coil model Q6, remove the metal washer

www.hitchcocksmotorcycles.com

Summary of Contents for 350 BULLET 1956

Page 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...