ROYAL ENFIELD WORKSHOP MANUAL

Section L12 Page 5

fork ends. The rim should be trued as accurately

as possible, the maximum permissible run-out

both sideways and radially being plus or minus

1/32 in.

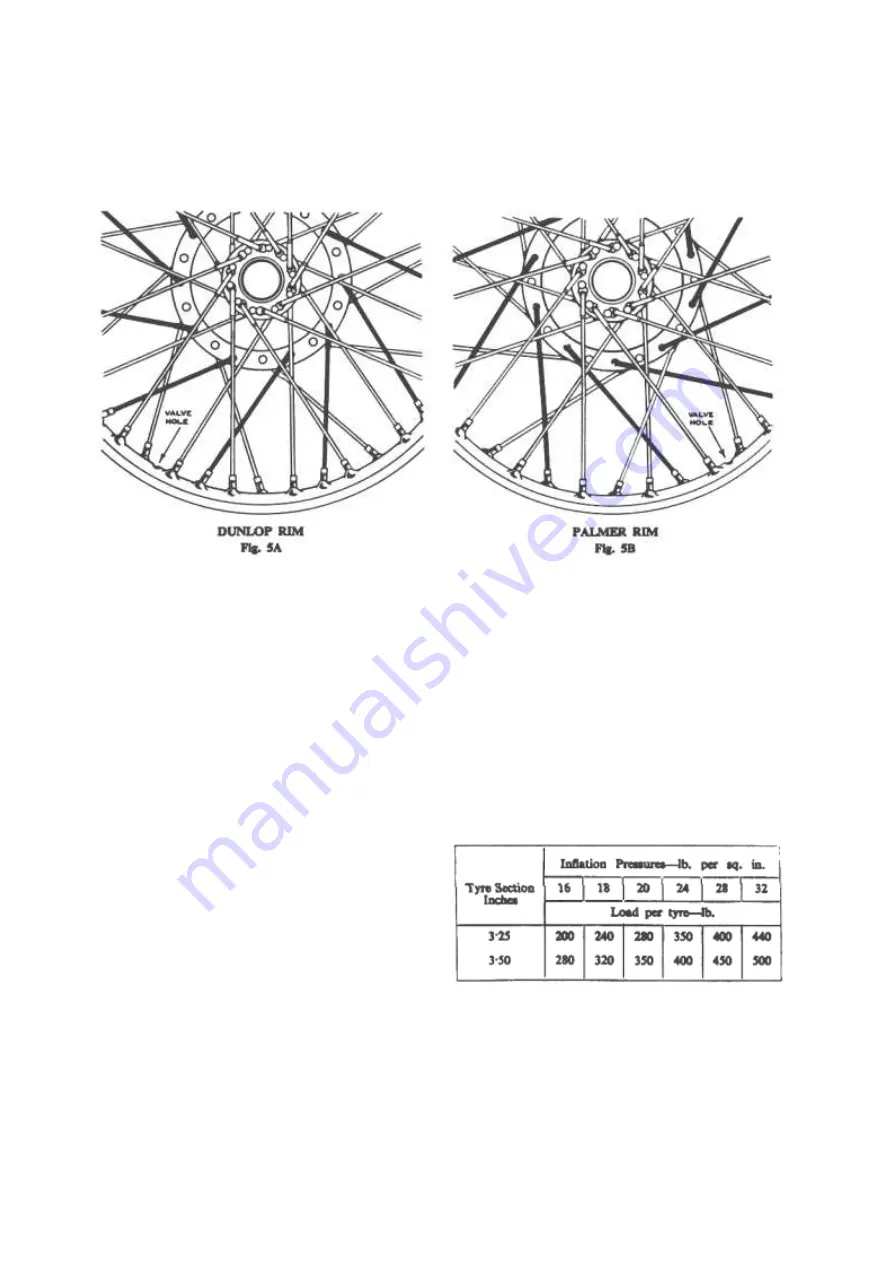

Fig. 5 shows the difference between the lacing

when using Dunlop and Palmer rims. The key to

correct lacing is the inside spokes to the large

flange on the cush drive shell which must slope in

the direction shown in Fig. 5. With the Dunlop

rim this spoke goes to the middle hole of one of

the groups of three (see paragraph 14) and the rim

must be built into the wheel so that these groups

of three holes are on the right of the centre line

when the cush drive is on the left, i.e. the inside

spokes to the large flange cross from the left to

the right of the centre line.

With the Palmer rim the spokes from the large

flange on the cush drive shell go to the more

steeply angled holes in the rim which must be on

the left of the centre line when the cush drive is

on the left, i.e. none of the spokes crosses from

left to right of the centre line.

17. Tyres

Standard tyres are Dunlop 3.50-19 in.

Universal tread except on the "350 Bullet" where

a 3.25-19 in. Universal tyre is used.

When removing the tyre always start close to

the valve and see that the edge of the cover at the

other side of the wheel is pushed down into the

well in the rim.

When replacing the tyre fit the part by the

valve last, also with the edge of the cover at the

other side of the wheel pushed down into the

well.

If the correct method of fitting and removal of

the tyre is adopted it will be found that the covers

can be manipulated quite easily with the small

levers supplied in the toolkit. The use of long

levers and/or excessive force is liable to damage

the walls of the tyre. After inflation make sure that

the tyre is fitting evenly all the way round the rim.

A line moulded on the wall of the tyre indicates

whether or not the tyre is correctly fitted. If the

tyre has a white mark, indicating a balance point,

this should be fitted near the valve.

18. Tyre Pressures

The load which the tyre will carry at different

inflation pressures is shown below:

19. Lubrication

A greasing point is provided in the centre of

the hub barrel. Unless the barrel is packed full

with grease on assembly (which is apt to lead to

www.hitchcocksmotorcycles.com

Summary of Contents for 350 BULLET 1956

Page 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...