ROYAL ENFIELD WORKSHOP MANUAL

Section C14 Page 2

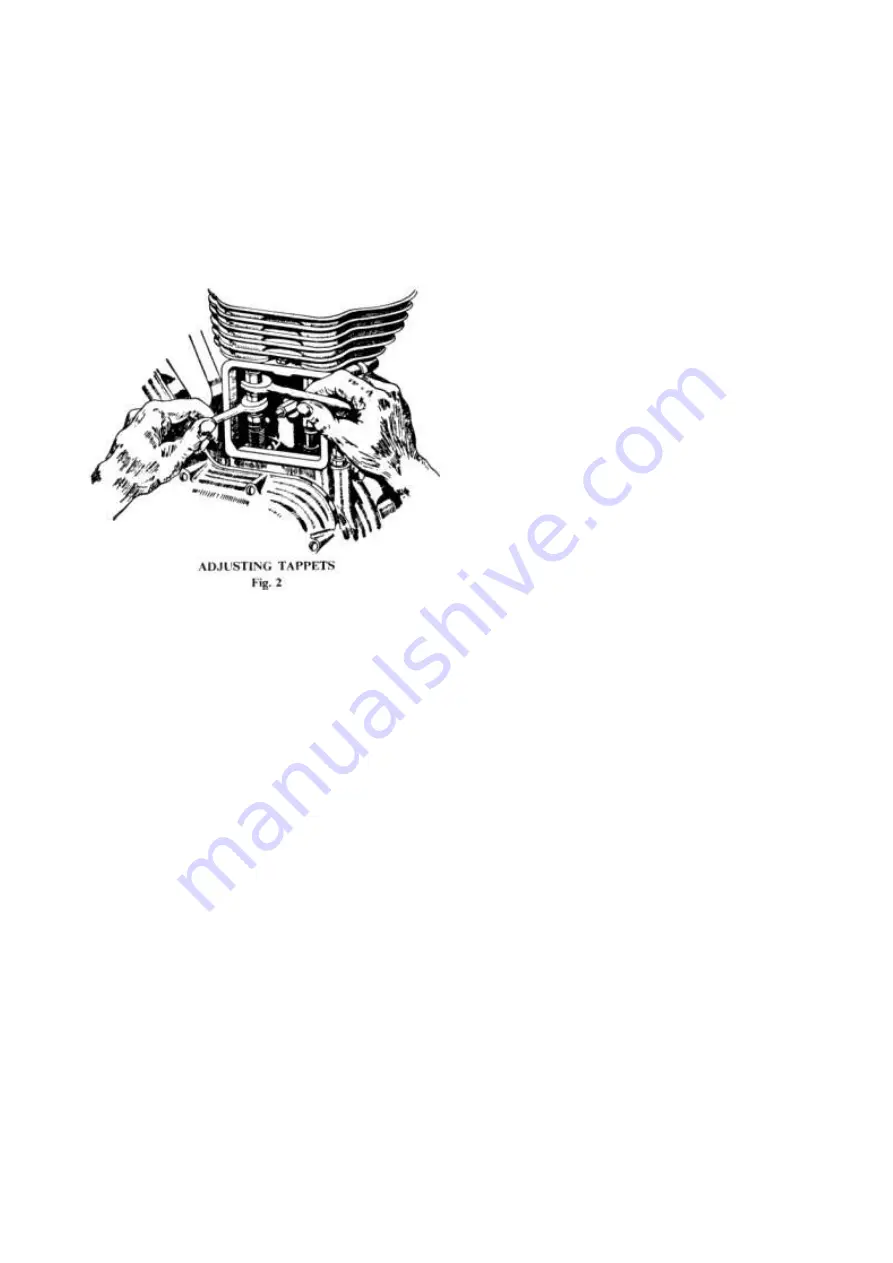

stems and rockers, with the rocker box covers

removed. To remove the rocker box covers the

petrol tank must be taken off. (See Subsection 5.)

The correct clearance is nil or as little as

possible with the engine COLD.

To make the adjustment hold the push rod

bottom end (top hexagon) and turn the locknut

(middle hexagon) to the left. Screw the push rod

cup (bottom hexagon) to the left to take up

clearance or to the right to increase the clearance,

at the same time holding the push rod bottom end

(top hexagon). Lock the adjustment by tightening

the locknut against the push rod end and then

recheck the clearance.

Owing to the initial bedding down of the

wearing surfaces, the tappets on new engines may

require adjustment after the first few hundred

miles.

4. Ignition Timing

The setting of the ignition depends upon the

position of the magneto or contact breaker drive

pinion relative to the shaft.

To obtain access to the pinion it is necessary to

remove the timing cover (see Subsection 1).

On engines fitted with magneto and

autoadvance mechanism, the latter is in unit with

the driving pinion, and is held to the shaft on a

smooth taper and secured by a nut having a

right-hand thread.

There is some difference in all "350 Clipper"

(see subsection 18) and all "Trials" models, and in

"350 and 500 Bullets" from 1960 onwards.

To remove the pinion and the auto-advance

device, unscrew the nut and this will draw the

pinion off.

Before setting the timing remove the magneto

cover and adjust the contact breaker points to a

clearance of .015 in. when fully opened.

Because of the auto-advance mechanism, the

timing is normally in the "retard" position when

the engine is stationary. Rotate the two halves of

the coupling relatively to each other against the

springs, i.e. into the "advance" position, and hold

it in this position by a piece of wire.

To set the timing, turn the engine until the

piston is 1/2-7/16 in. for the 350 c.c. Engine, or

3/8-5/16 in. for the 500 c.c. Engine, before top

dead centre on the compression stroke, i.e. with

both valves closed.

Insert a thin piece of paper between the point

of the contact breaker and turn the magneto

forwards (or clockwise looking on the contact

breaker) until the paper can just be pulled out.

Tighten the pinion and auto-advance device on

to the shaft, taking care that it does not slip.

Remove the piece of wire holding the

auto-advance mechanism.

The timing can be checked by removing the cap

from the magneto and holding the rotor in the

advanced position by means of a screwdriver,

without the necessity of taking off the timing

cover.

On no account must the cam be altered

from its original position on the rotor shaft or

the efficiency of the magneto will be affected.

For all "350 Clippers," the auto-advance

mechanism used is of a different type from that on

the "350 Bullet" up to 1959, and the engine must

be checked and set in the fully retarded position.

This and the following remarks apply to "350 and

500 Bullets," 1960 onwards.

Gap setting should be .015 in. to .018 in. and

the engine should be timed so that the contact are

on the point of opening when the piston is 1/16 in.

before top dead centre.

The best way to check the opening point is to

switch on the ignition and rotate the engine slowly

until the ammeter needle returns to its central

position.

To adjust the timing, slacken the clamping bolt

on the contact breaker housing and rotate the

housing. If the timing cover has been dismantled,

start with the contact breaker housing so that the

name on the cover is roughly horizontal.

"Works Replica." The contact breaker should

be set so that the points are just breaking when the

piston is 7/16 in. before top dead centre on the

compression stroke, ignition fully advanced.

5. Removal of the Petrol Tank

Turn off the petrol tap.

Disconnect the petrol pipe.

Remove the bolt which holds the front of the

tank to the frame, pull upward, to release the

spring clip holding the tank at the rear.

www.hitchcocksmotorcycles.com

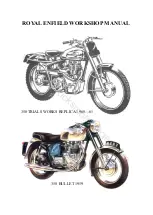

Summary of Contents for 350 BULLET 1956

Page 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...