WORKSHOP MANUAL BULLET

Page 14

6. Piston and Rings

If the piston rings are in good condition they can be put back, taking care to fit them in their

original grooves and the same way up. If the rings show brown or black patches or if their gaps, are

more than specified service limits, when in position in the barrel, new rings should be fitted. The

correct gap for new rings is given in the technical specifications. The gap should be measured in the

least worn part of the cylinder which will be found at the top or bottom of the bore.

The original size of the cylinder bore is 2.751" (69:875mm). If the wear at any point in the bore

exceeds .008" the cylinder should be rebored to .020" and an oversize piston fitted. (It should be

rebored to .040" after a further. 008" wear). Piston sizes available are .020" and .040" oversize.

The original side clearance between the piston rings and

grooves is .003". If the grooves show a wear of .005" the piston

should be replaced.

7. Big end bearing inspection

Examine the condition of the big end while the piston is

removed. About .010" - .020" end float is permissible and it

will be possible to rock the connecting rod slightly. The big end

has a floating bush with an original clearance of approximately

003". However, if a DEFINITE up and down play can be felt,

engine should be stripped further to have the big end renewed.

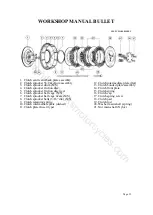

CRANKSHAFT BIG END BEARING

Remove carbon from the valves,

ports and combustion chamber by

scraping. Take care not to cause any

damage to the valve faces or valve

seat inserts. Scrape gently to avoid

scoring the cylinder head.

DO NOT, under any circumstance,

use caustic soda or potash for the

removal of carbon from aluminium

alloy.

Remove the piston rings carefully.

For cleaning the groove in the piston,

a piece of broken piston ring thrust

into a wooden handle and filed to a

chisel point can be used:

5. Decarbonising the Cylinder head - Combustion Chamber

CYLINDER HEAD

www.hitchcocksmotorcycles.com

Summary of Contents for 350 BULLET 1989

Page 9: ...WORKSHOP MANUAL BULLET Page 9 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 17: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 34: ...WORKSHOP MANUAL BULLET Page 34 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 37: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 41: ...WORKSHOP MANUAL BULLET Page 41 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 58: ...WORKSHOP MANUAL BULLET Page 58 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 69: ...WORKSHOP MANUAL BULLET Page 69 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 73: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 77: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 103: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 105: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 107: ...WORKSHOP MANUAL BULLET Page 107 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 108: ...WORKSHOP MANUAL BULLET Page 108 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 109: ...WORKSHOP MANUAL BULLET Page 109 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 110: ...WORKSHOP MANUAL BULLET Page 110 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 111: ...WORKSHOP MANUAL BULLET Page 111 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 113: ...WORKSHOP MANUAL BULLET Page 113 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...