WORKSHOP MANUAL BULLET

Page 21

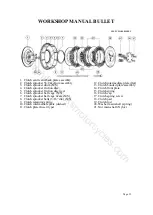

CAM TIMING MARKS

A: MARK ON INLET CAM

B: MARK ON EXHAUST CAM

C: MARK ON TIMING PINION

5. Removal of Contact breaker housing.

Loosen the distributor pinion nut and pull out the distributor pinion off the distributor shaft after

removing the idler pinions.

Loosen and remove the three screws which secure the spigotted contact breaker housing and

seperate from crankcase. Remove the contact breaker cover. Remove the base plate after removing the

two hex bolts securing it.

Pull out the contact breaker shaft from the housing. The two sintered bushes provided in the

housing would have to be replaced only if excessive radial play is noticed on the distributor shaft.

Reassembly is just the reverse process of dismantling but take care to replace the washer between

the contact breaker housing and the crank case.

6. Valve Timing

The cams are integral with the cam pinions. They

have internal sintered iron bushes running on fixed

spindles in the timing chest.

The cams and the timing pinion are provided with

timing marks to set proper valve timing. The procedure

is detailed below.

Bring the piston to TDC position. Match the exhaust

cam (provided with two sets of punch marks with the

timing pinion so that the two punch marks coincide on

both. Match the inlet cam to the exhaust cam so that the

single punch marks coincide on both. Push the cams

home towards the crankcase.

7. Tappet Adjustment – Cold

It is very essential to ensure that the valves are

closed fully during the closing period of the cam.

The tappet clearance should be adjusted properly to

achieve this and to cater to certain amount of

thermal expansion of the working components. We

recommend 'NIL' clearance for the tappets to be set

at cold. Provision for adjustment is given at the

bottom end of the push rod which sits over the

tappet. Access to this is by removing the tappet

cover.

Proceed as follows for adjustments. Bring the piston

to TDC at the end of compression stroke, so that

both the valves are at the closed position. This may

be ensured by seeing the valve timing marks, if the

timing cover is open or through ammeter needle in

its centre position, when ignition is switched on.

ADJUSTING TAPPETS

www.hitchcocksmotorcycles.com

Summary of Contents for 350 BULLET 1989

Page 9: ...WORKSHOP MANUAL BULLET Page 9 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 17: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 34: ...WORKSHOP MANUAL BULLET Page 34 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 37: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 41: ...WORKSHOP MANUAL BULLET Page 41 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 58: ...WORKSHOP MANUAL BULLET Page 58 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 69: ...WORKSHOP MANUAL BULLET Page 69 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 73: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 77: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 103: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 105: ...w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 107: ...WORKSHOP MANUAL BULLET Page 107 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 108: ...WORKSHOP MANUAL BULLET Page 108 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 109: ...WORKSHOP MANUAL BULLET Page 109 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 110: ...WORKSHOP MANUAL BULLET Page 110 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 111: ...WORKSHOP MANUAL BULLET Page 111 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 113: ...WORKSHOP MANUAL BULLET Page 113 w w w h i t c h c o c k s m o t o r c y c l e s c o m ...