ROYAL ENFIELD WORKSHOP MANUAL

Section L2 Page 3

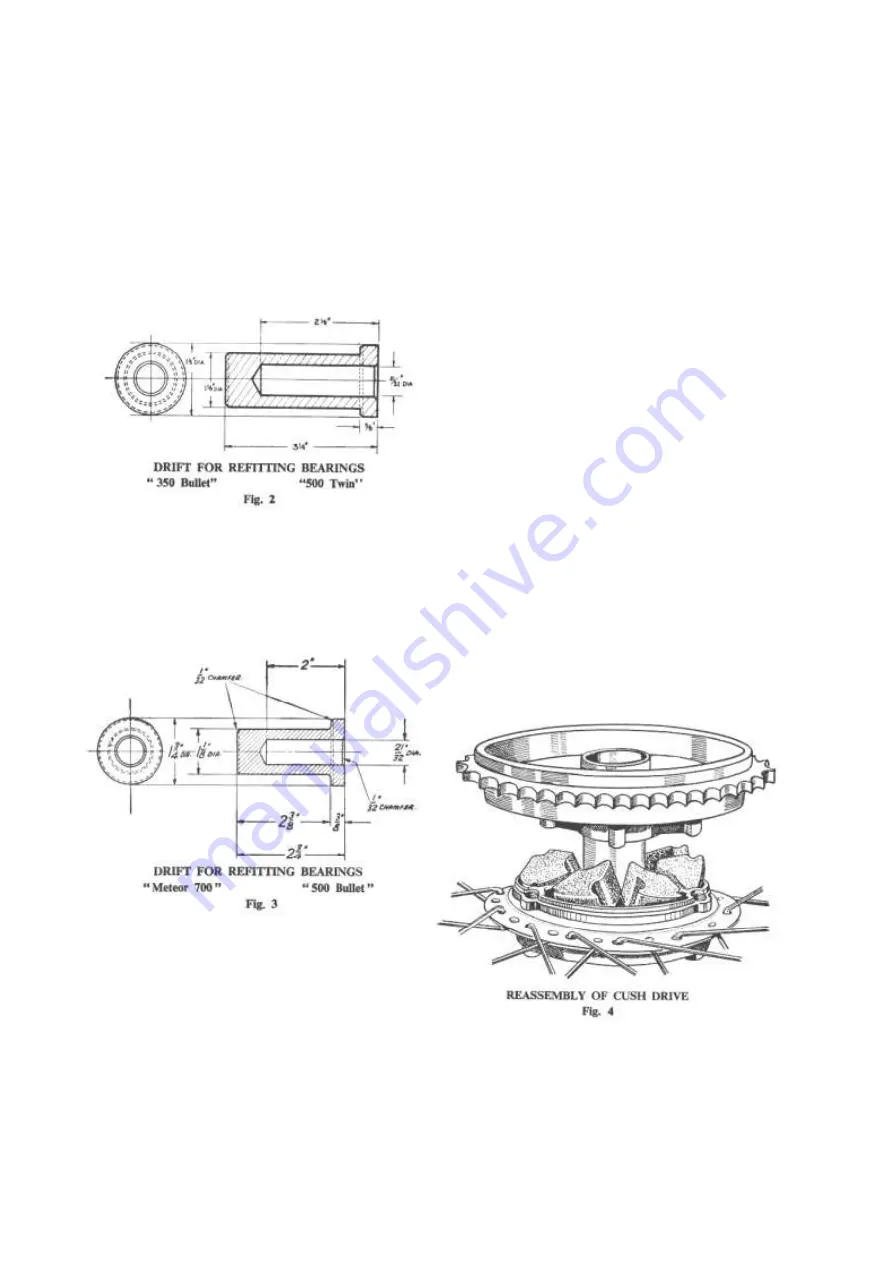

entered into one end of the hub barrel which is then

supported on one of the hollow drifts. The other

bearing is then threaded over the upper end of the

spindle and driven home by means of the second

hollow drift either under a press or by means of a

hammer which will thus drive both bearings into

position simultaneously.

In order to make quite sure that there is clearance

between the inner faces of the outer bearings and the

bottom of the recesses fit the distance washers against

the inner races of the bearings and either fit the

assembly of brake cover plate, speedometer gearbox,

etc., or make up this distance with tubular distance

pieces. Fit and tighten the spindle nuts. Tightening the

nuts should not have any effect on the ease with

which the spindle can be turned. If tightening the nuts

makes the spindle hard to turn this may be taken as

proof that the bearings are bottoming in the recesses

in the hub barrel before they are solid against the

shoulders on the spindle. In this case the bearing

should be removed and a thin packing shim fitted

between the inner race and the shoulder on the

spindle.

9. Removal of Brake Operating Cam and Brake

Shoe Pivot Pin

The method of doing this has already been

described in Paragraph 3 dealing with the 6 in. brake.

The method is precisely the same for the 7 in. brake

except that, owing to the different type of return

springs used, it is, in this case, possible to remove the

shoes from the pivot pin and operating cam before the

latter are removed from the cover plate.

10. Cush Drive

The sprocket/brake drum is free to rotate on the

hub barrel. Three radial vanes are formed on the back

of the brake drum and three similar vanes are formed

on the cush drive shell. Six rubber blocks are fitted

between the vanes on the brake drum and those on

the cush drive shell, thus permitting only a small

amount of angular movement of the sprocket/brake

drum relative to the hub barrel and transmitting both

driving and braking torque and smoothing out

harshness and irregularity in the former.

If the cush drive rubbers become worn so that the

amount of free movement measured at the tyre

exceeds 1/2 in. to 1 in., the rubbers should be

replaced. To obtain access to them remove the

complete wheel as described above, remove the brake

cover plate complete with the brake shoe assembly,

unscrew the three Simmonds nuts at the back of the

cush drive shell, if necessary holding the studs,

32431, by means of the flats on the heads inside the

brake drum. Drive out the three studs into the brake

drum after which the sprocket/brake drum can be

separated from the cush drive shell and the six cush

drive rubbers can be lifted out.

www.hitchcocksmotorcycles.com

Summary of Contents for 500 TWIN 1949

Page 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 51: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 63: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 81: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 91: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 108: ...ROYAL ENFIELD WORKSHOP MANUAL NOTES w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 109: ...ROYAL ENFIELD WORKSHOP MANUAL NOTES w w w h i t c h c o c k s m o t o r c y c l e s c o m ...