ROYAL ENFIELD WORKSHOP MANUAL

SECTION K2

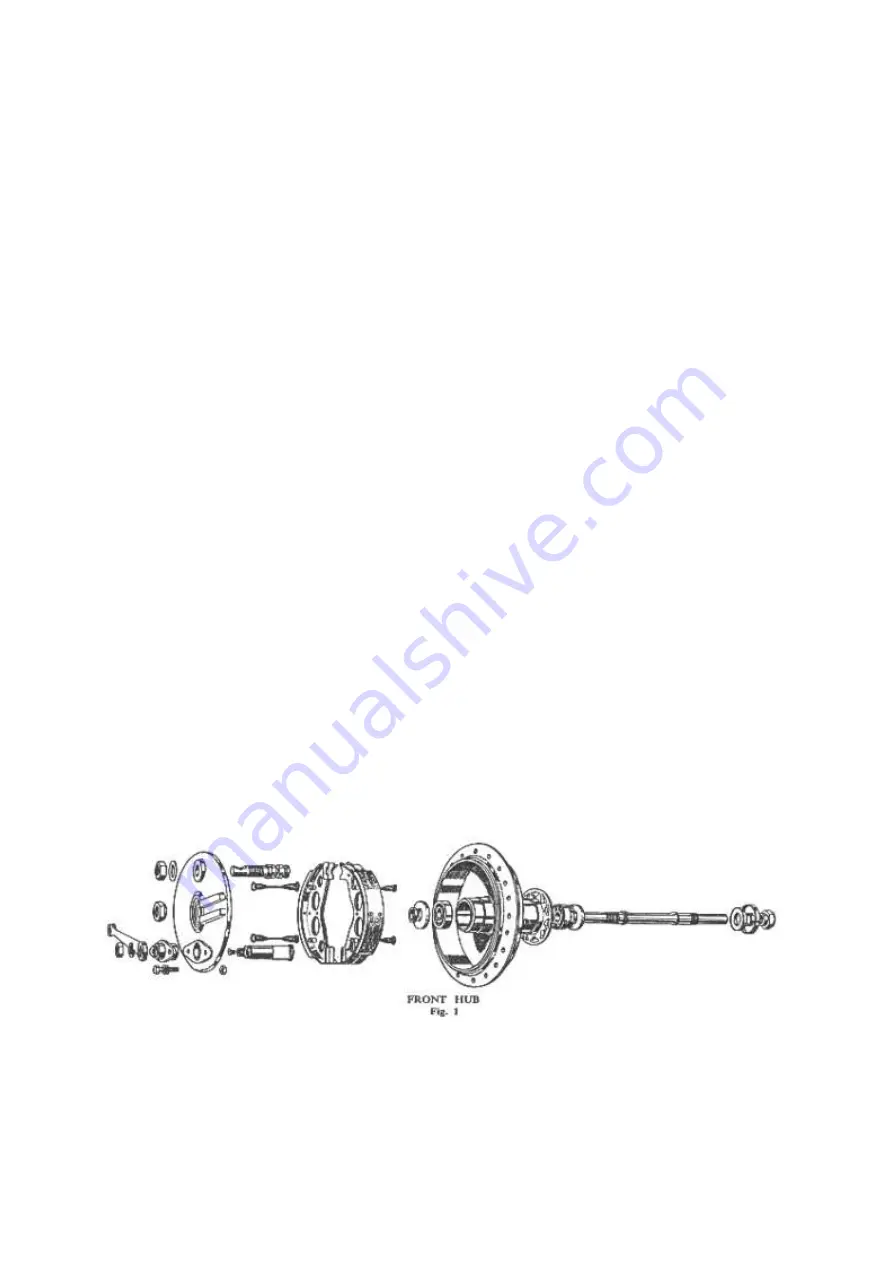

Front Wheel

With Single 6 in. Brake

Fitted to 250 Clipper, Model S, G, J and J2.

Also 350 + 500 Bullet, and 500 Twin up to the end of 1954

1. Removal from Fork

To remove the front wheel from the fork,

place the machine on the centre stand (in the

case of the spring frame models) with

sufficient packing (about 2 in.) beneath each

side of the stand to lift the wheel clear of the

ground when tilted back on to the rear

wheel. In the case of Models S, G and J

place the machine on the rear stand and

place a suitable box or block beneath the

crankcase to lift the front wheel clear of the

ground. Slacken the brake cable adjustment

and disconnect the cable from the handlebar

lever and

from the operating cam lever on

the hub. Unscrew the four nuts securing the

fork bottom tube lug caps (Part No. 38593)

and allow the wheel to drop forwards out of

the front fork. Make sure that the machine

stands securely on the rear wheel

and centre

stand-if necessary place a weight on the

saddle or a strut beneath the fork to ensure

this.

2. Removal of Brake Cover Plate Assy.

Lock the brake "on" by pressure on the

operating lever and

unscrew the cover plate

nut. The cover plate assembly can then be

withdrawn from the brake drum.

3. Removal of Brake Shoes and Springs

This is best done by unscrewing the

pivot pin locknuts and the operating lever

nuts after which the assembly of brake

shoes, return springs, pivot pin and

operating cam can be removed from the

cover plate by light blows with a hammer

and drift on the ends of the pivot pin and the

operating cam. The return springs can then

be unhooked from the spring posts in the

brake shoes thus allowing the whole

assembly to fall apart.

4. Replacing Brake Linings

Brake linings are supplied either in pairs

ready drilled complete with rivets (Part No.

37786BX) or ready fitted to service

replacement brake shoes (Part No. 38042).

When riveting linings to shoes secure the

two centre rivets first so as to ensure that

the lining lies flat against the shoe. Standard

linings are Ferodo MR41, which are drilled

to receive cheese headed rivets.

5. Removal of Hub Spindle and Bearings

To remove the hub spindle and bearings

having first removed the

brake cover plate,

unscrew the retaining nut and remove the

dust excluder from the non-brake side of the

hub. Now remove the felt washers and the

distance washer from the brake side and hit

one end of the spindle with a copper

hammer or mallet, thus driving it out of the

hub bringing one bearing with it and leaving

the other in position in the hub. Drive the

bearing off the spindle and insert

Section K2 Page 1

www.hitchcocksmotorcycles.com

Summary of Contents for 500 TWIN 1949

Page 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 51: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 63: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 81: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 91: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 108: ...ROYAL ENFIELD WORKSHOP MANUAL NOTES w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 109: ...ROYAL ENFIELD WORKSHOP MANUAL NOTES w w w h i t c h c o c k s m o t o r c y c l e s c o m ...