ROZUM ROBOTICS

PULSE robotic arm

Page

16 | 23

2.3.1. Power connection

The power connection of the control box is in accordance with the IEC 60320-1 C14 standard.

The

electrical specifications are as indicated in Table 2-1.

Table 2-1: Electrical specifications of the control box power connection

Parameter

Value/ range

Unit

Input voltage

100–264

VAC

Mains frequency

47–63

Hz

Standby power

10

W

Average operating power

400

W

For enhanced safety, consider installing an external mains switch with a fuse.

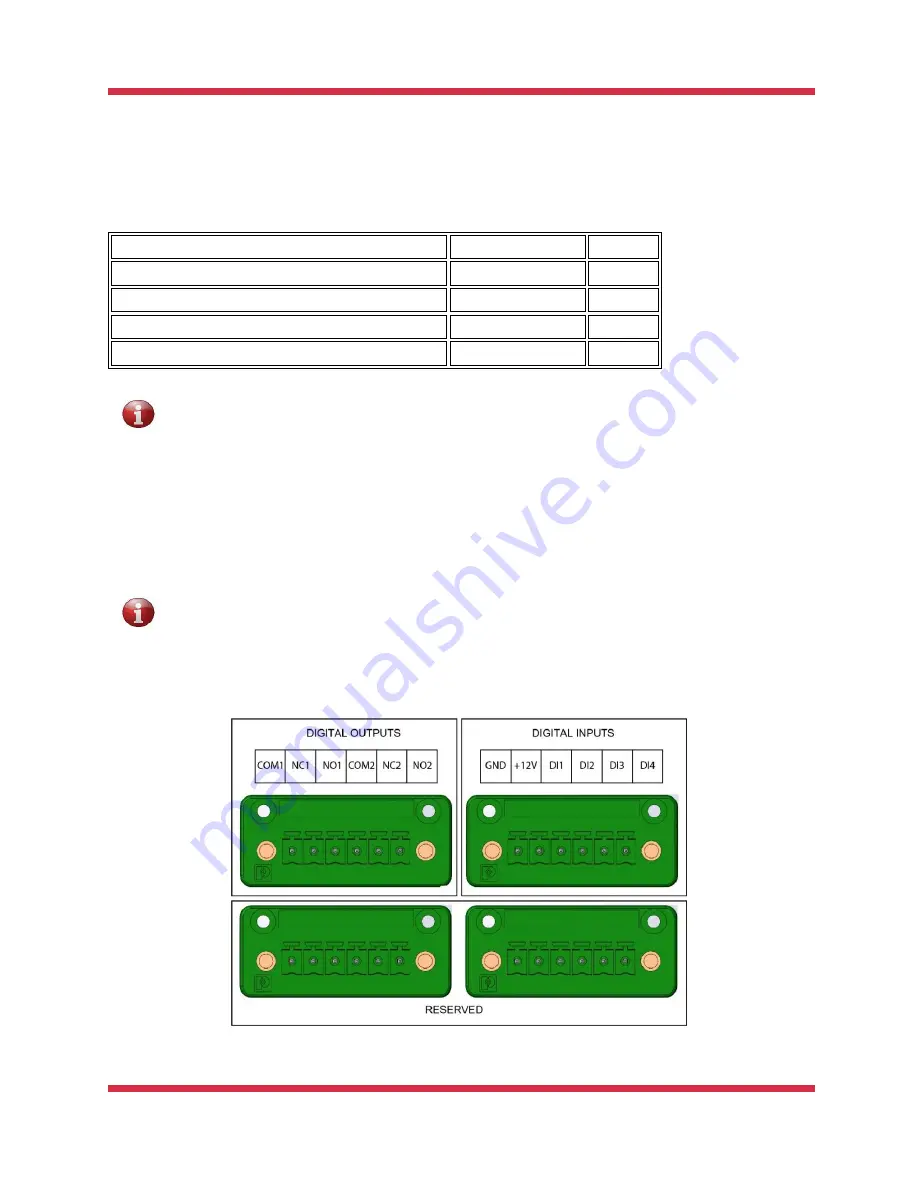

2.3.3. Digital I/O connectors

The control box has 4 digital inputs and 2 digital outputs that you can use to connect additional

equipment, including sensors, safety devices, PLC, etc. The connectors are located on the back

panel of the control box (see Figure 1-6).

The cable length from the digital inputs/ outputs to connected equipment should not

exceed 2 m. Otherwise, signal quality may suffer.

For the current control box configuration, the two lower digital I/O connectors have the

RESERVED status. The pin assignment for the two upper ones is as illustrated in Figure 2-2.

Figure 2-2: Pin assignment for digital I/O connectors

Summary of Contents for Pulse

Page 1: ......