Valid from: 11/2011

Technical changes reserved

Page 9

Doc.: OM_VIAS & VICD (10D)

8.3.

Special cleaning hints

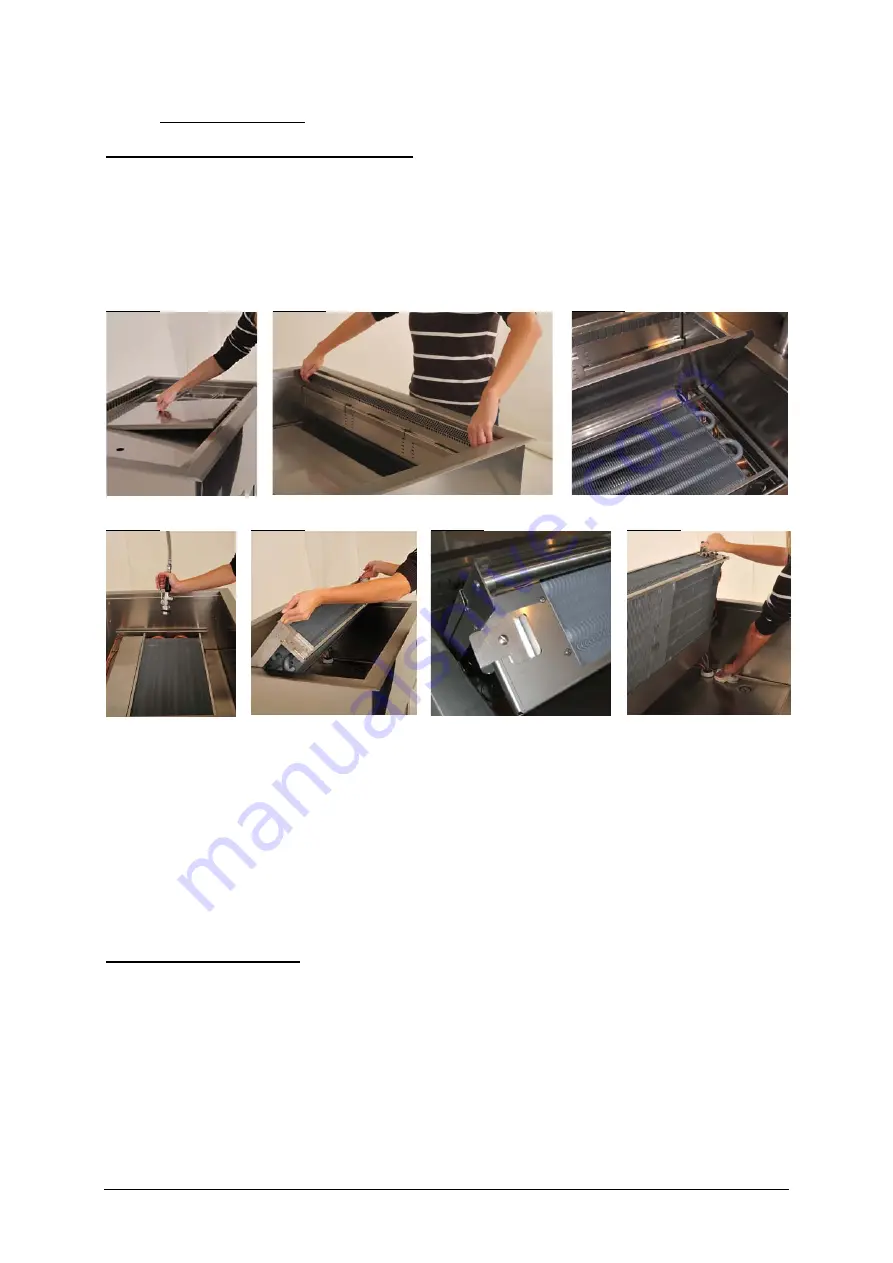

Cleaning of the interior and evaporator coil

Take out the GN containers or base decks

(1)

and air plenums

(2)

and inner tray from the well.

First of all remove visible dirt inside the well (bottom) to avoid a blockage of the drain

(5 und 6)

.

Open the cover from the evaporator unit

(3)

. Entire s/s housing and evaporator coil can be rinsed

safety and easily with a hand spray

(4).

Fans in low voltage (24V) allow danger-free cleaning. Lift

up the evaporator unit and move the lock to the left

(5 und 6)

– now the evaporator is fixed and

allows easy access for cleaning corners and floor of the well

(7)

.

Picture 1

Picture 2

Picture 3

Picture 4

Picture 5

Picture 6

Picture 7

ATTENTION

: Before cleaning the unit with water please check that the water can run off. If the

unit isn’t plumped to a floor drain, place an external bin below the drain to collect the wastewater.

The evaporator and the interior have to be cleaned with lukewarm soap water. Always dry the

interior after cleaning. After cleaning lift the evaporator, remove the lock and drop the evaporator

back in its original position.

Insert the inner tray, position the air plenums with the hanging tracks and drop in the base decks

or GN containers.

Never clean the outside of the refrigerated well with a water hose or an abrasive sponge. Avoid

flowing water near these areas.

All other surfaces can be cleaned with soft detergents or water.

Cleaning of condenser unit

Each self-contained refrigeration unit requires periodic cleaning of the condenser unit.

The condenser coil (looks like a radiator and is directly in front of the fan) requires periodic cleaning.

A dirty condenser is the main cause of refrigeration overheating, burnout and poor cooling levels.

Similar to the daily merchandise area cleaning, it is necessary to remove the static dust build up from

the condenser coils to ensure effective and trouble free operation.

The condenser should be thoroughly cleaned monthly (under extreme conditions clean more often)!

Important

: Warranty void if this service is neglected or temperature controls interfered with.