5.5.1.2 - End-of-day-wash procedure

▪

End-of-day wash:

All pipettes will be washed once and needle, fill-nozzle and rinse-nozzle (wash station) are primed.

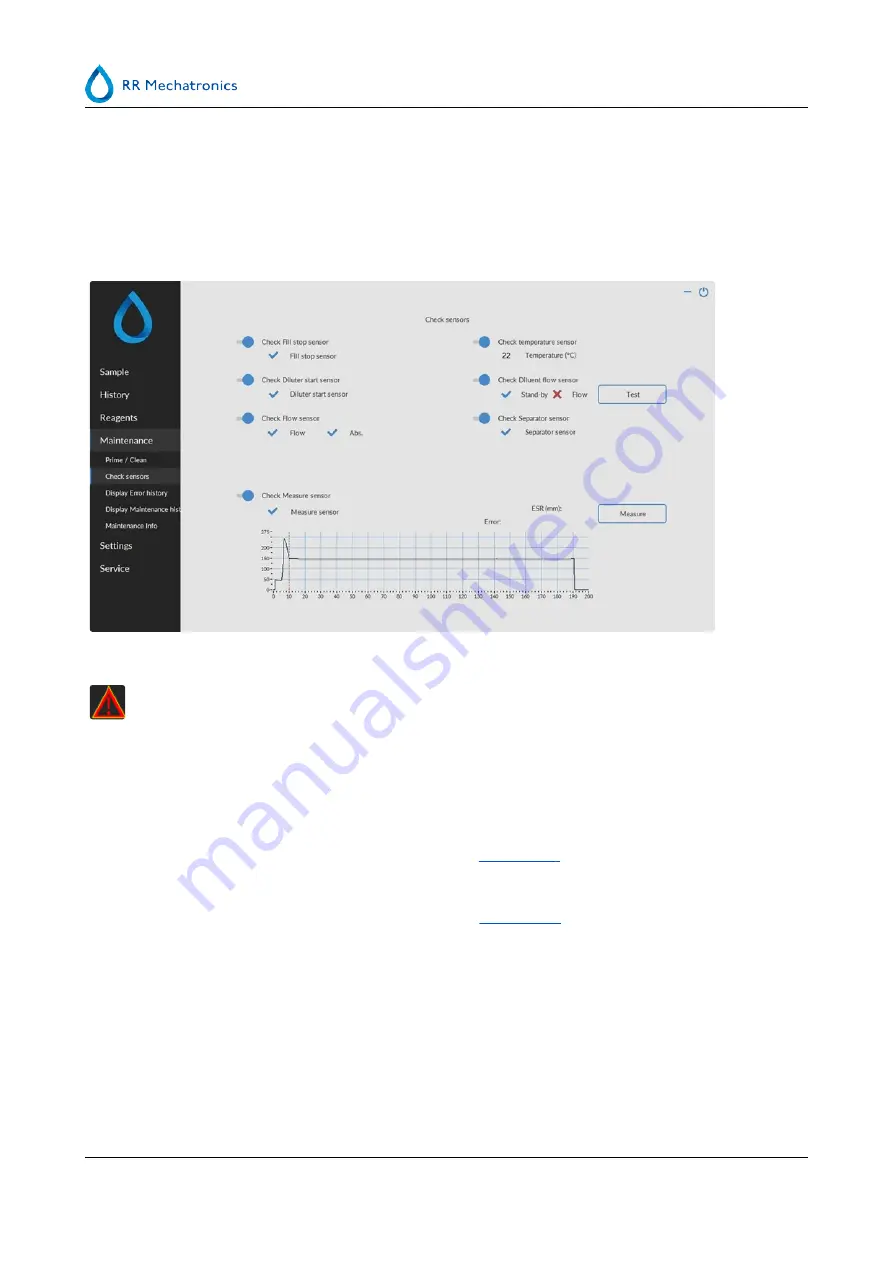

5.5.2 - Check sensors

When there is a sensor alarm, an alarm indicator is shown in the tab

Maintenance

.

All functions to check the status of the sensors are grouped under button

Check sensors

.

▪

Check Fill stop sensor: Click the Check button, the OK sign is shown if the sensor value is in range.

▪

Check temperature sensor: Value must be equal to the actual room temperature near the pipette belt.

The value can be set in tab

Settings

.

▪

Check Diluter start sensor: This sensor is only used in

. If the diluter does not start during

the aspiration, the status of this sensor must be checked.

Click the Check button, the OK sign is shown if the sensor value is in range.

▪

Check Diluent flow sensor: This sensor is only used in

. When activated, the indicator

Stand-by is activated and the indicator Flow is not. When the button Test is clicked, the indicator Flow

must be shown as "activated". After finishing the test, both indicators must be shown as "activated".

▪

Check Separator sensor: Click the Check button, the OK sign is shown if the sensor value is in range.

▪

Check Flow sensor: Click the Check button, the OK sign is shown if the sensor value is in range.

▪

Check Measure sensor:

Clean sensor first before executing this function.

Click the Check button, the OK sign is shown if the sensor value is in range.

Starrsed program

52

MRN-164_2-EN Version 2.02 Interrliner