3

Note: These die sets are to be used in conjunction with tool frame RS

stock no. 849-114 and for crimping the above contacts:

Installation and removal of die set and locator

assembly (figure 1)

1. Open the tool handles and remove the two die retaining screws

from the tool jaws.

2. Place the wire anvil and insulation anvil so that their chamfered

sides and their marked surfaces face outward, when mounted in the

lower jaw of the tool frame.

3. Insert the two die retaining pins.

4. Insert the short die retaining screw through the jaw and both anvil

dies, and tighten the screw just enough to hold the dies in place.

Do not tighten the screw completely at this time.

5. Place the wire crimper and insulation crimper so that their

chamfered sides and their marked surfaces face outward, when

mounted in the upper jaw of the tool frame.

6. Insert the two die retaining pins.

7. Insert the long die retaining screw through the jaw and both crimper

dies, and tighten the screw just enough to hold the dies in place. Do

not tighten the screw completely at this time.

8. Carefully close the tool handles, making sure that the anvils and

crimpers align properly. Continue closing the tool handles until the

ratchet in the tool frame has engaged sufficiently to hold the anvils

and crimpers in place, then tighten both die retaining screws.

9. Place the locator assembly over the end of the long screw, and

position the locator assembly against the side of the tool jaw.

10. Place the nut onto the end of the long screw and tighten the nut

enough to hold the locator assembly in place, while still allowing the

locator to slide up and down.

11. To disassemble, close the tool handles until the ratchet releases,

remove the nut, the locator assembly, the two die retaining screws,

and the four die retaining pins, and slide the anvils and crimpers out

of the tool jaws.

Contact support adjustment (figure 2)

Note: The contact support is preset prior to shipment, but minor

adjustment may be necessary.

1. Make a simple crimp and determine if the contact is straight,

bending upward, or bending downward.

2. If adjustment is required, loosen the screw that holds the contact

support onto the locator assembly.

Note: The ratchet has detents that create audible clicks as the tool

handles close.

3. Place a contact with wire into the proper nest and close the tool

handles until the ratchet reaches the sixth click, or until the contact

support touches the contact.

4. Slightly loosen the nut that holds the locator assembly onto the tool

frame.

5. Move the contact support as required to eliminate the bending of the

contact.

6. Tighten the nut and close the handles until the ratchet releases.

7. Remove and inspect the contact.

8. Make another sample crimp. If the contact is straight, tighten the

contact support screw. If the contact is still being bent during

crimping, repeat the adjustment procedure.

Crimping procedure (figures 2 and 3)

With the correct contact and wire size as defined in the table above,

strip the wire back to give 4mm of conductor. Proceed as follows.

1. Hold the tool so that the back (wire side) is facing you. Squeeze tool

handles together and allow them to open fully.

2. Holding the contact by the mating end, insert the contact - insulation

barrel first - into the appropriate crimp section.

3. Position the contact so that the mating end of the contact is on the

locator side of the tool, and so that the open "U" of the wire and

insulation barrels face the top of the tool. Place the contact up into

the nest so that the movable locator drops into the slot in the

contact. Refer to figure 3. Butt the front end of the wire barrel

against the movable locator.

CAUTION: Make sure that both sides of the insulation barrel are

started evenly into the crimping section. Do not attempt

to crimp an improperly positioned contact.

4. Hold the contact in position and squeeze the tool handles together

until the ratchet engages sufficiently to hold the contact in position.

Do not deform insulation barrel or wire barrel.

5. Insert stripped wire into contact insulation and wire barrels until it is

butted against the wire stop, as shown in figure 3.

6. Holding the wire in place, squeeze tool handles together until

ratchet releases. Allow tool handles to open and remove crimped

contact.

Note:

The crimped contact may stick in the crimping area, but

the contact can be easily removed by pushing downward

on the locator (see figure 3).

RS Components shall not be liable for any liability or loss of any nature (howsoever

caused and whether or not due to RS Components’ negligence) which may result

from the use of any information provided in RS technical literature.

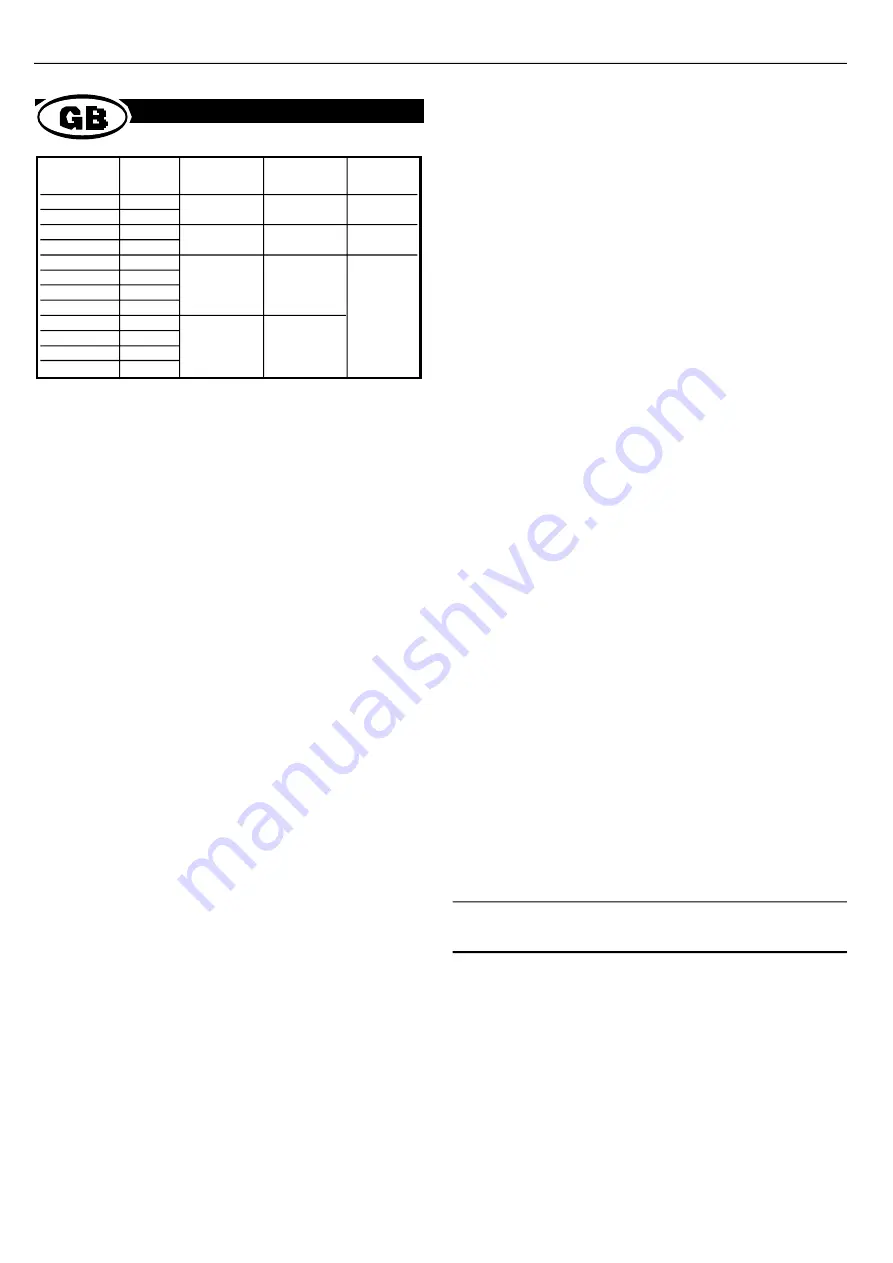

Wire size

RS

stock no. Contact

Conductor

Insulation

Die Set

849-079

pin

24-18 a.w.g.

1-2.5mm

849-136

849-091

socket

849-085

pin

20-14 a.w.g.

1.5-3.3mm

849-120

849-108

socket

372-377

pin

372-406

socket

24-20 a.w.g.

1.02-2.03mm

372-850

pin

372-412

socket

372-440

372-383

pin

372-428

socket

18.16 a.w.g. 2.03-2.54mm

372-399

pin

372-434

socket

.

V9720