ORACLE2 Owner's Manual

18

RSF Woodburning Fireplaces

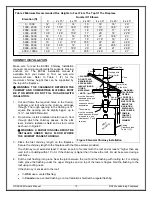

To convert the ORACLE2 please carefully follow the following steps:

1. There is a 1 ¼" hole on both sides of the fireplace, about 12 ¾" up from the bottom of the fireplace. The gas

line must come into the fireplace through one of these holes. Choose the side of installation that is more

convenient to you.

2. There are a few parts that you need to remove from the ORACLE2 to be able to accommodate a gas firelog.

Make sure to store them for safekeeping, you will need to reinstall them all if you ever intend to burn wood

again in your ORACLE2:

•

Remove both bottom refractory bricks from the firebox.

3. You will need to drill four 1" diameter holes on the bottom of the firebox. They should be aligned, parallel to

the doors and half way between both doors. They should be 6" spaced apart, center to center, and centered

between both side refractory bricks.

4. The right side refractory bricks (11.2.R) already have a hole to allow the gas line through. You only need to

clean out the gray sealant out of the hole on the selected installation side to be able to pass the gas line

through and into the firebox.

5. Make sure to leave the four holes completelly open, this will bring air to the gas log.

6. Proceed with the installation of the gas log as per the gas log manufacturer installation instructions. Make

sure to carefully read and follow the gas log installation instructions. Make sure also to respect all clearances

stated by the gas log manufacturer.

WARNING: THE MAXIMUM GAS OUTPUT ALLOWED IN THE ORACLE2 IS 40,000 BTUS. THE GAS LOG

HAS TO BE LISTED TO ANSI Z21.60/CSA 2.26.

When operating an ORACLE2 with a gas log installed, make sure to follow the gas log manufacturer operating

instructions.