PEARL 3600 Owner's Manual

11

RSF Woodburning Fireplaces

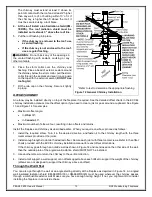

8. Orient the outside air elbow in the direction you want the outside air duct to go and tighten the screws.

9. Make a 4 ¼" (5 ¼" if using a 5" diameter duct) hole in the outside wall of the house. Push the outside air inlet

in from the outside. Seal the joint between the air inlet and the outside wall with an appropriate sealant.

10. Place the insulated flexible duct over the round sleeve on the outside air inlet. Carefully pull back the insulation

and plastic cover, exposing the flexible duct. Attach the duct with metal screws to the air inlet. Replace the

insulation and cover back over the duct. Tape the plastic cover in place with aluminium duct tape.

CAUTION: WHEN RUNNING THE DUCT AROUND CORNERS, BE SURE TO PREVENT CRIMPING THE

DUCT IN A WAY THAT WOULD RESTRICT THE COMBUSTION AIRFLOW.

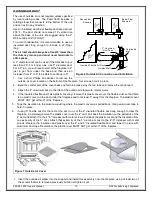

FINISHING AROUND THE FIREPLACE

The decorative faceplate of the PEARL3600 fireplace is not meant to be covered, it is meant to be admired.

DO

NOT

cover the decorative faceplate of the fireplace or any of its louvers.

The decorative faceplate of the PEARL3600 extends ½" beyond the sides of the fireplace to be able to hide the

edge of the finishing material behind it. The decorative faceplate sits 1" proud of the top of the fireplace casing to

allow thin finishing materials to slip behind the rounded top of the decorative faceplate.

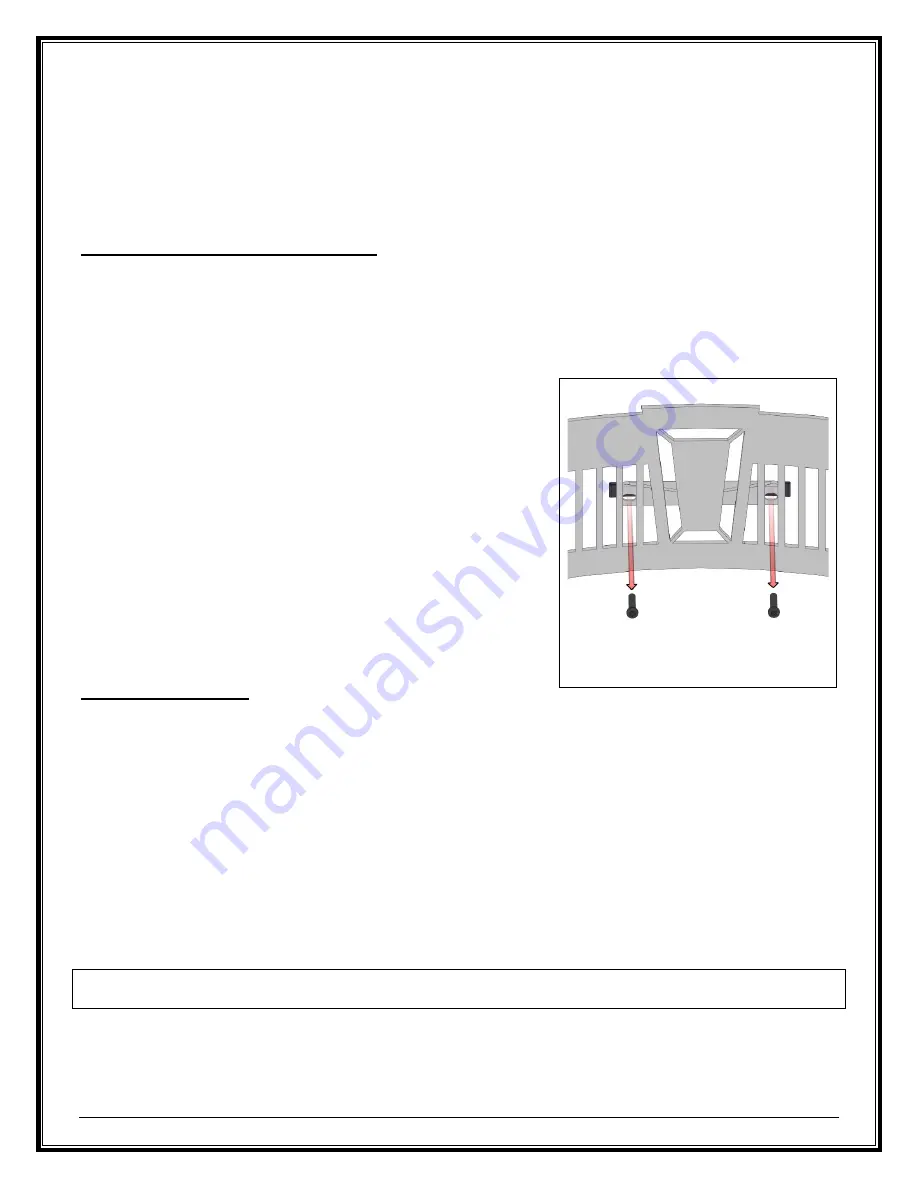

Before you begin, remove the decorative faceplate and bottom louver

to prevent damaging them while installing the finishing materials. To

remove the faceplate, use a 5/32 Allen key and remove the two screws

located on either side of the faceplate’s keystone centerpiece (see

Figure 8) Once the bolts are removed, the faceplate will be loose, so

with one hand holding the faceplate in place, close the door. Take a

good grip on both side of the faceplate and lift it up. There are two

brackets, one on each lower side, that need to be disengaged from the

base of the fireplace. Do not lose the hardware that secures the

faceplate to the fireplace.

To remove the bottom louver, simply open the door, grab the top of the

louver close to each extremity and pull forward. There are two high

temperature magnets, one on each side, close to the top of the louver

keeping it in place along with two supports close to the bottom of the

louver to support the weight of the louver.

If desired, you can also remove the glass door by lifting it off its hinges

Facing Requirements

Finishing materials that cover the facing of the fireplace MUST BE NON-COMBUSTIBLE (e.g. brick, slate, ceramic

tile, etc.). Drywall cannot get closer to the fireplace than the side and top standoffs. The front face of the top standoff

is considered part of the fireplace facing. The minimum size of a non-combustible facing is shown in Figure 9.

The non-combustible finishing materials may be installed so that they fit behind the decorative faceplate. Plan the

finishing of the fireplace in advance and plan for the material thickness including the adhesive coat. If you are using

a thin material (such as tile) and plan to install your finishing behind the decorative faceplate, you MUST be able to

reinstall the decorative facing properly or it may become a safety hazard.

NOTE:

There is only 1” between the decorative faceplate and the fireplace body. For example, this is sufficient

for a ½” cement board, a

⅛”

adhesive coat, and a

⅜

” tile.

You can also finish your PEARL3600 with materials that will result in a combined thickness greater than 1" (e.g.

brick, stone, etc.). These materials will not fit behind the decorative faceplate and will protrude past the faceplate

once installed.

If you are using thick finishing materials, then the decorative faceplate of the PEARL3600 can

be used as a template.

WARNING

Gypsum boards or any other combustible material cannot touch the casing of the fireplace. Only non-

combustible material such as cement board can touch the fireplace casing.

Figure 8 Location of the Screws

Securing the Decorative Faceplate