PEARL Owner's Manual

21

RSF Woodburning Fireplaces

down from the top of the chimney.

If you are using a rigid liner you will need enough room to secure an elbow to it with at least two screws.

If it is difficult to install rigid stainless steel liner in the existing masonry chimney or for a masonry chimney

with less than 10"x10" inside, a listed stainless steel flexible liner can be used along with a flexible/rigid

adaptor (LM-7LAF) available from your RSF dealer.

4. Install the liner elbow and masonry adaptor on the lower end of the liner.

5. Move the fireplace forward enough to install the EXCEL chimney on the fireplace (elbow and length) then

move the fireplace back into position as you connect the masonry adaptor to the EXCEL chimney.

Using a New Masonry chimney

Since the masonry chimney is not build yet, we recommend that you position your fireplace, install the EXCEL

chimney on it and connect to the first length of liner before building the chimney as explained above and shown in

Figure 15 . The liner sections can easily be installed as the layers of brick are being placed. Since this is a new

chimney, we recommend that you build it to the right size so you do not have to ovalize the liner.

Remember:

The stainless steel liner should be fitted inside the clay liner all the way to the top of the masonry

chimney. It is not meant to replace the clay liner.

HEARTH EXTENSION

The area immediately in front of the fireplace must be protected by a non-combustible material such as brick, tile,

stone, or slate. Refer to Table 1 (G-H) for the depth and width that the hearth protection should extend beyond the

front and both sides of the door opening (see Figure 1). There is no minimum thickness required for the hearth

extension.

BENEATH THE HEARTH EXTENSION

If the PEARL is installed on a non-combustible floor,

NONE of the cement board and the spark guard

specified below is not required.

Install the spark guard provided (5" x 36" piece of

sheet metal) halfway under the fireplace and halfway

under the hearth extension and centered on the door

opening. The spark guard will extend 2½" beneath the

fireplace. This will make certain that sparks cannot

lodge in this area and start a fire. If necessary, the

provided spark guard can be cut to the minimum

width specified in Table 1 (I).

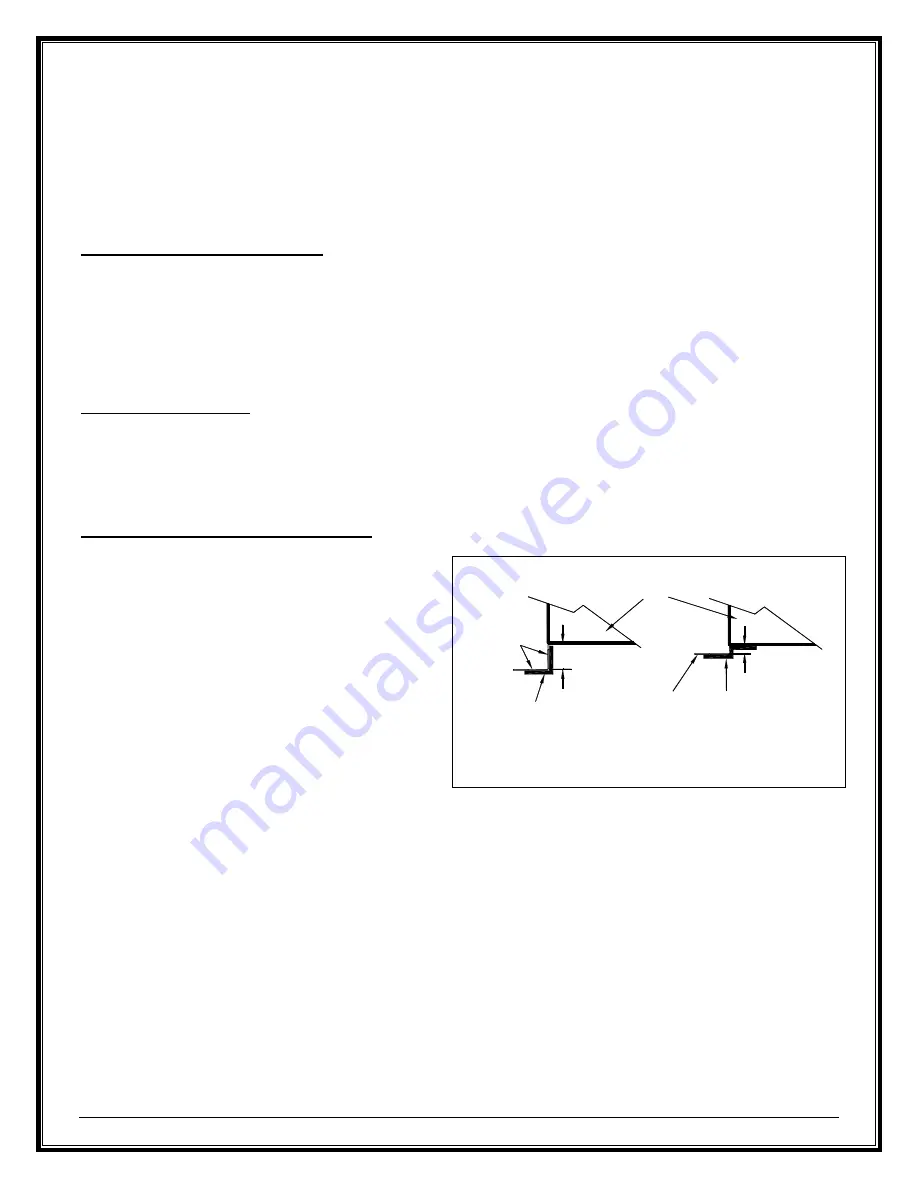

If you are preparing a raised installation, you will need

a custom made spark guard, either a "Z" shaped

spark guard or a right angle spark guard (see Figure 16). The Z-shaped spark guard must be used if the height

between the bottom of the fireplace and the top of the non-combustible flooring of the hearth extension is less

than or equal to 2 ½". The height of the Z-shaped spark guard must equal the distance between the floor and the

base of the unit and go under the hearth extension and the fireplace by at least 2½". If the unit is installed higher

than 2 ½" from the top of the flooring, a right angle spark guard is necessary. The sides of the right angle spark

guard should be at least 2½" x 2½" and must be covered with non-combustible material. Any custom made spark

guard must have the minimum width specified in Table 1(I), and be installed centered on the door opening.

NOTE

: Custom-made spark guards are site built.

In the USA only:

A ½" cement board, such as Durock®, HardieBacker ® or equivalent, MUST be installed beneath the hearth

extension. The cement board must have the same minimum dimensions as the hearth extension (see Table 1

(G-H)). If the fireplace is raised by at least 4", the cement board is NOT required.

The spark guard must be installed under any of the layers of the hearth extension.

Figure 16 Special Custom-made Spark Guard

Non-

Combustible

Flooring

Right Angle

Spark Guard

(not provided)

More than 2 1/2"

Non-

Combustible

Flooring

Z-Shaped Spark

Guard (not

provided)

2 1/2" or less

RSF

Fireplace