ORACLE

page 16

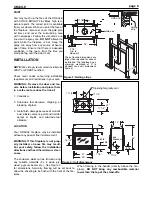

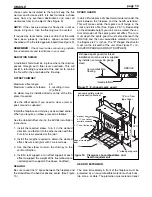

2. The grill adaptor is designed to be installed underneath

the gypsum board in the wall. In the desired location,

frame a 13" x 13" hole to accept the gravity vent grille

adaptor. Fit the gravity vent grille adaptor into the framed

hole and fasten it into place with nails or screws.

3. Remove the outer cover to the left, right, or both sides

of the flue outlet, on the ORACLE.

4. Cut the insulation to the size of the opening and remove

the cover plate underneath (it is taped in place).

5. Install the B-vent starter section. The slot in the B-vent

starter section should be facing the front and the hole

should be facing the back. Bend up the four tabs at the

base of the starter section to hold it in place.

6. Install the "shut off" damper at the base of the starter

section. The shut off damper enables the manual con-

trol of hot air flowing through the gravity vent pipe. With

the top louvers removed and the angular portion of the

rod in hand, insert the damper rod into the hole in the

starter section. Next, make sure that the washer and

spring on the control arm are both on the outside of the

starter section and that the rod has fit snugly into the

slot. A definite tension should exist between the shut off

damper rod and the starter section. Replace the lou-

vers. The damper rod should protrude above the top of

the louvers.

7. Install the B-vent pipe, between B-vent starter and the

grille adaptor. Fasten each joint with 3 screws. Insert the

B-vent pipe into the grille adaptor and fasten it with three

screws. The B-vent pipe needs only be inserted far

enough to be able to screw it into place. This allows you

about 3 ½" of adjustment.

8. Once the wall facing around the gravity vent grille adap-

tor has been completed, install the grille with the sup-

plied screws. The gravity vent is now ready for opera-

tion.

GAS LOG OPTION

The Oracle now features a gas conversion option. You can

use your choice of gas log sets with this conversion. The

installation of the gas should only be done by qualified per-

sonnel. To convert the Oracle for use with the gas log

option:

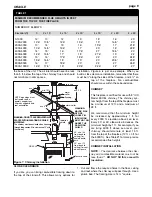

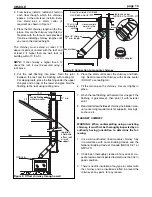

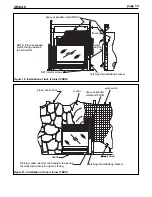

1. You will notice a 1 ¼" diameter knockout on both sides

of the Oracle, about 9" up from the bottom of the fire-

place (see Figure 4). The gas line will be installed

through one of these knockouts. Choose the side that

is best for your installation.

2. Remove the firebrick from the base of the firebox. You

will notice two sheet metal pieces underneath the fire-

brick. Remove these also. Keep the firebrick and sheet

metal, as they will be needed to operate the Oracle, if

you would like to burn wood again.

3. Underneath the firebrick and sheet metal, there are four

1" diameter holes in the center of the bottom, to bring air

to the gas log set. These holes must not be blocked.

4. There are two 1 ¼" diameter holes closer to the sides of

the bottom of the firebox. If you are installing a gas

valve, install it over one of these larger holes, to allow

the airflow to cool the gas valve.

5. When you remove the firebrick you will notice a notch in

the bottom of the side refractories. The gas line will

come through one of these notches (see Figure 19).

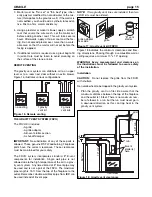

6. Follow the instructions supplied with your gas log set

concerning the installation of gas lines, shut-off valves,

etc. If you have the sand pan type of gas log set that

covers the air holes, place some of the firebrick, or

some other suitable non-combustible material around

the edges of the sand pan to raise the gas log set above

the air holes.

Maximum gas input: 40 000 BTU

There are no minimum clearances to the sides or top of the

firebox. However, any clearances stated by the gas log set

manufacturer must be maintained.

You may install the gas valve inside the firebox if the gas log

set manufacturer allows this in its instructions, and the

required clearances are met.

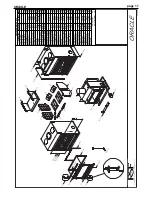

gas knockout

13 1/4”

gas log set of

your choice

Figure 19: Gas log option

4”