Real Time Automation, Inc.

23

1-800-249-1612

8)

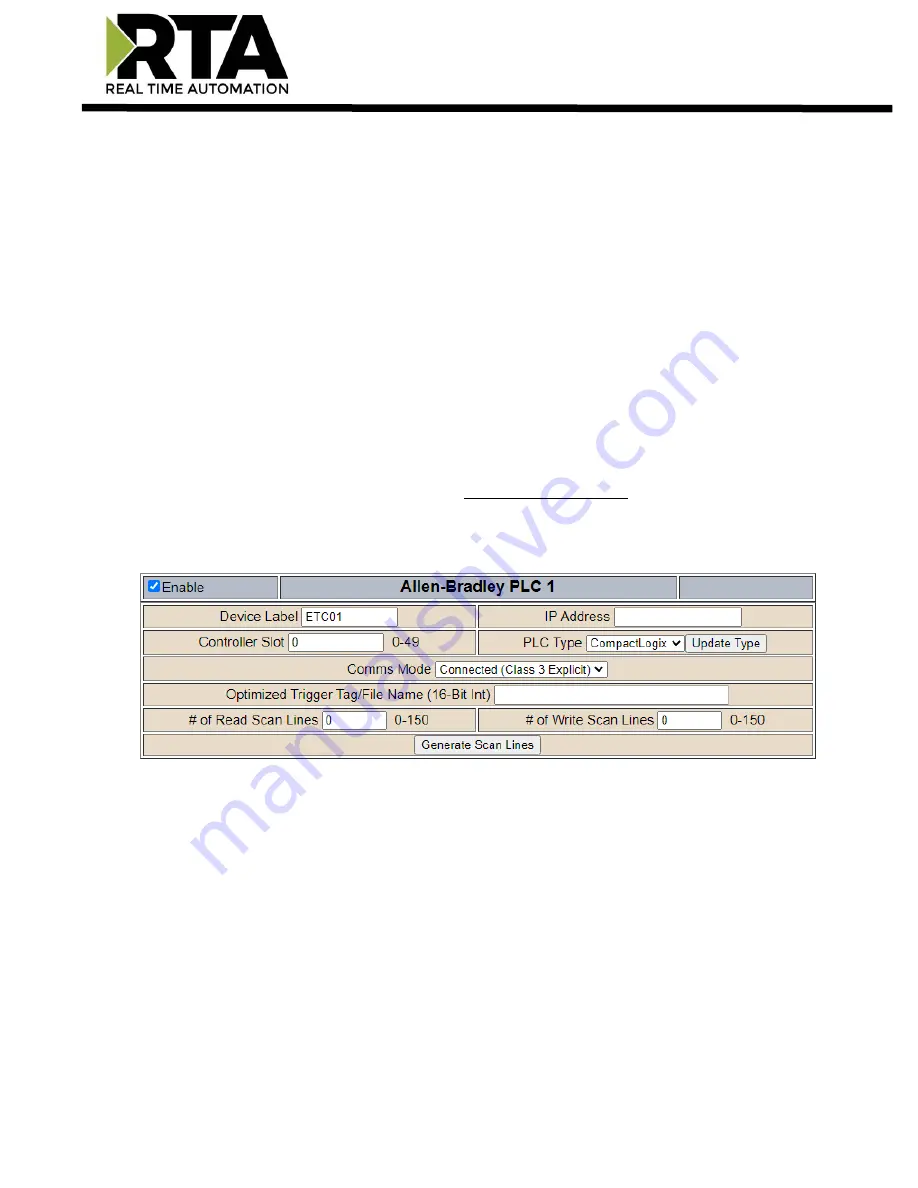

Enter the

IP Address

of the PLC, the

Controller Slot

(Integrated Ethernet, use Slot 0), and select the

PLC Type

. The Controller Slot is the slot where the controller is located, not the Ethernet card being

used. These three parameters must match the PLC you are communicating to.

NOTE: ControlLogix Rev 32 is ONLY supported with CompactLogix 5380 and above and

ControlLogix 5580 and above

.

9)

Select the

Comms Mode

.

Unconnected (UCMM)

messaging relies on shared resources to transfer

data to the PLC. This could result in message timeouts if there are a lot of devices fighting for these

shared buffers. If you don’t want the RTA gateway to constantly keep the con

nection open to the

PLC but only maintain a connection when there is data needed to be transferred, then Unconnected

(UCMM) will work best if you are only writing to the PLC.

Connected

(Class 3 Explicit)

messaging

relies on reserved resources to transfer data to/from the PLC

. Connected (Class 3 Explicit)

messaging is recommended if you are reading and writing and always want to keep that connection

open to the PLC.

10)

Enter an

Optimized Trigger Tag/File Name

to enable the triggering optimization that is available.

The Optimized Trigger forces the 460ETC gateway to read ONLY the Optimized Trigger Tag until a

value has a change of state. Please

reference

the Optimized Trigger Guide in the section below.

11)

Enter the “# of Read Scan Lines” and “# of Write Scan Lines”.

12)

Click

Generate Scan Lines

to have the read and write scan lines auto generated for you. If you need

to manually configure the read and write scan lines you can do so after they have been generated.