Real Time Automation, Inc.

68

1-800-249-1612

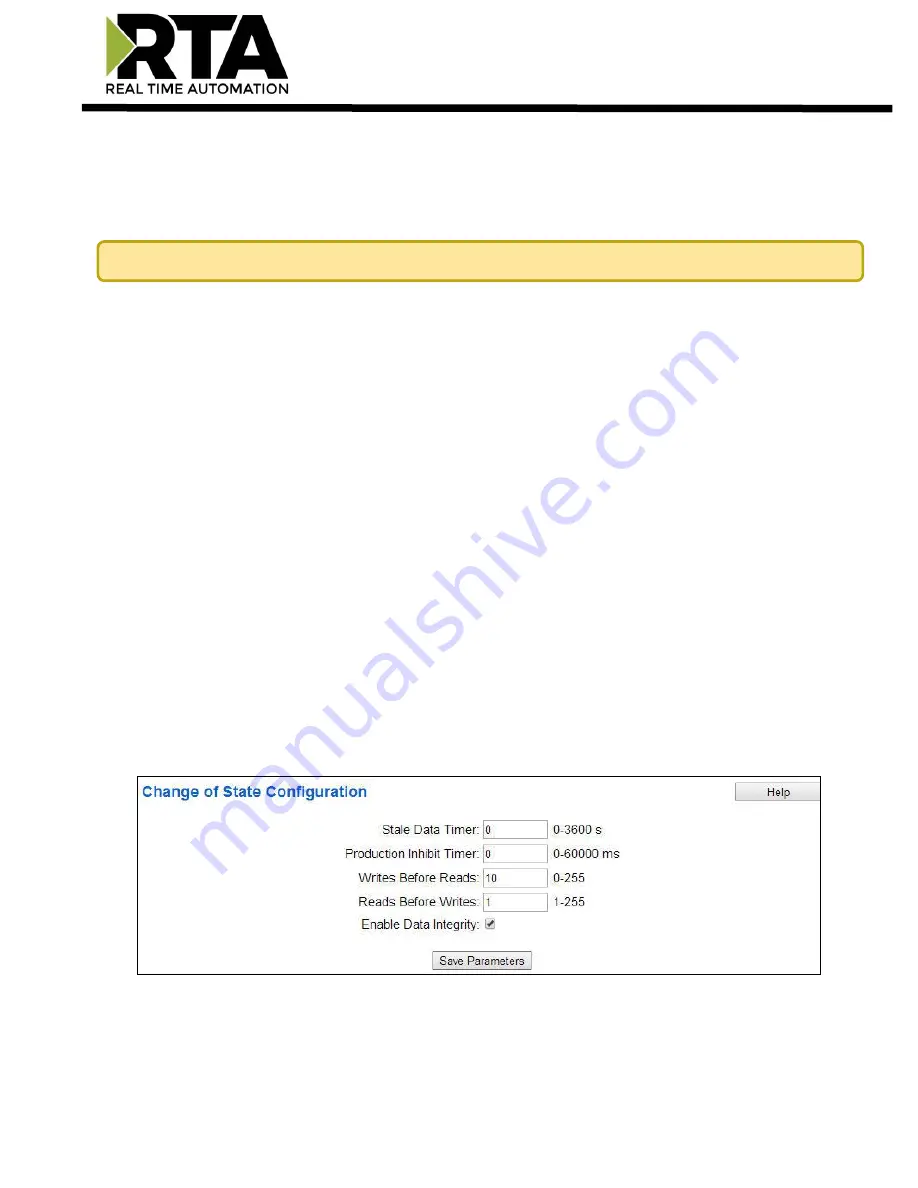

Change of State (COS) Configuration

To access the configuration files in the 460 gateway, navigate to dropdown

Other->COS Configuration

.

The gateway, by default only writes when data has changed. The gateway also waits to write any data to

the destination until the source protocol is successfully connected.

1)

Stale Data Timer

: If the data has not changed within the time allocated in this Stale Data Timer,

the data will be marked as stale within the gateway and will force a write request to occur. This

timer is to be used to force cyclic updates in the gateway, since data will only be written if it has

changed by default. There is a separate timer per data mapping.

Gateway behavior

:

•

If time = 0s => (DEFAULT) The gateway will write out new values on a Change of State

basis.

•

If time > 0s => The gateway will write out new values whenever the timer expires to

force cyclic updates (write every

x

seconds).

2)

Production Inhibit Timer:

Amount of time after a Change of State write request has occurred

before allowing a new Change of State to be written. This is to be used to prevent jitter. Default

value is 0ms. This timer takes priority over the Stale Data Timer. There is a separate timer per

data mapping. This timer is active only after the first write goes out and the first COS event

occurs.

3)

Writes Before Reads

: If multiple writes are queued, execute # of Writes Before Reads before the

next read occurs. Default is 10 and should fit most applications.

Warning

:

A value of 0 here may starve reads if a lot of writes are queued. This may be useful in

applications where a burst of writes may occur and you want to guarantee they all go out before

the next set of reads begin.

4)

Reads Before Writes:

If multiple writes are queued, the # of Writes Before Reads will occur

before starting the # of Reads Before Writes. Once the # of Reads Before Writes has occurred,

the counter for both reads and write will be reset. Default is 1 and should fit most applications.

5)

Enable Data Integrity

: If enabled, do not execute any write requests to the destination until the

source data point is connected and communicating. This prevents writes of 0 upon power up.

Click the

Save Parameters

button to commit the changes to memory and reboot the gateway.

Default values should fit most applications. Change these values with caution as they affect performance.