Einbau- und Betriebsanleitung

Installation and Operating instructions

SR3300-8010

SR-3300

Page 37

07/2018

7.

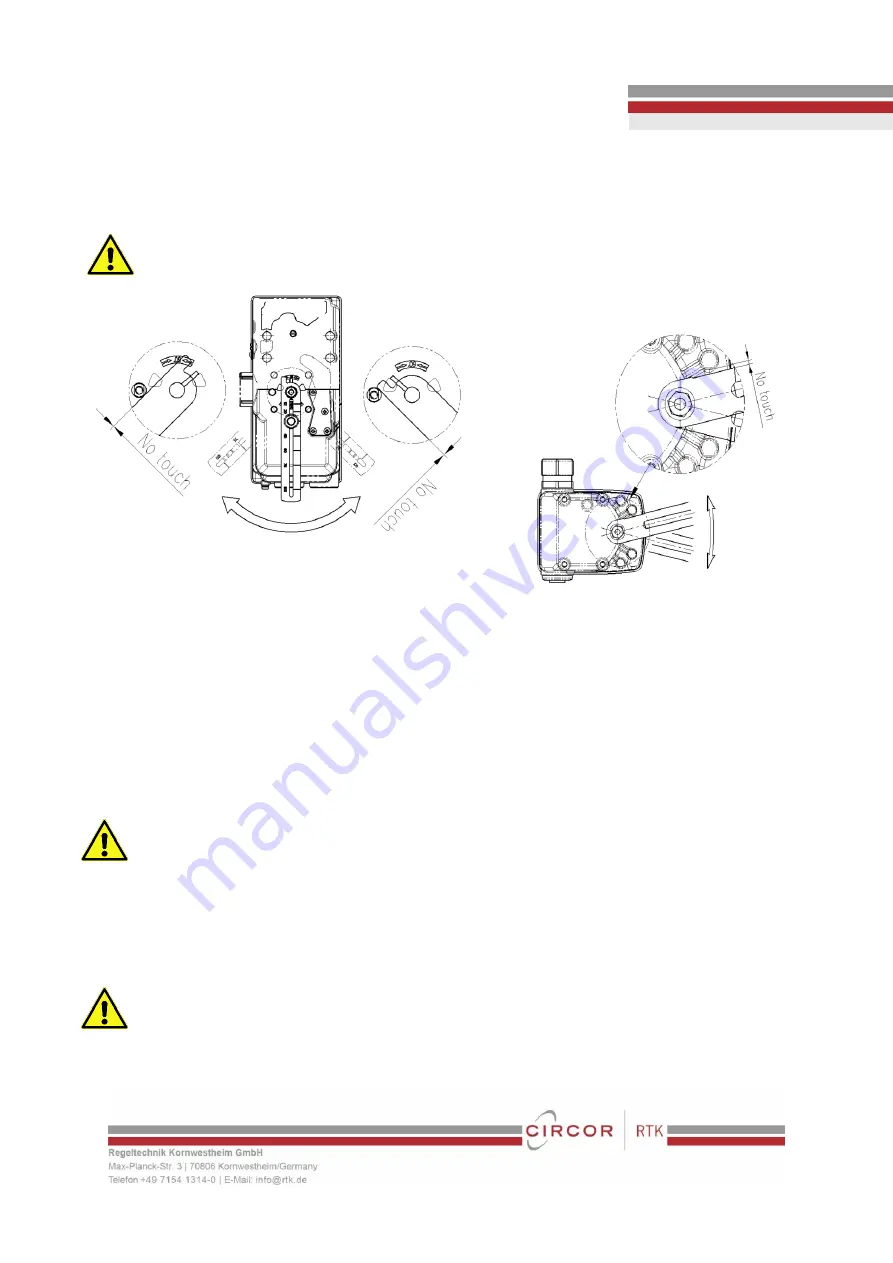

After installing the positioner, operate the valve from 0% to 100% stroke by using direct air to the actuator (manual position).

On both 0% and 100%, the feedback lever should not touch the lever stopper, which is located on the backside of the

positioner. If the feedback lever touches the stopper, the positioner should be installed further away from the yoke.

Feedback lever should not touch lever

stopper 0% ~ 100% valve stroke.

8.

After the installation, tighten all of the bolts on the bracket, the feedback lever, and the connection pin.

4.

Connections

4.1

Safety

➢

Supply pressure should be clean and dry air

–

avoiding moisture, oil or dust.

➢

Always recommended to use air filter regulator

➢

Young Tech Co., Ltd

has not tested positioner’s operation with any other gases other than clean air.

4.2

Supply Pressure Condition

➢

Dry air with at least 10

℃

lower than ambient temperature.

➢

Avoid from dusty air. Positioner’s inner filter can only filter 5

micron or larger.

➢

Avoid oil.

➢

Comply with ISO 8573-1 class 3

➢

Supply pressure range is 1,4 ~ 7 bar

➢

Set air filter regulator’s pressure level 10% higher than actuator’s spring range pressure.

4.3

Piping Condition

➢

Ensure inside of pipe is clean of obstructions.

➢

Do not use pipeline that is squeezed or shows any type of damamges.

➢

Pipeline should have more than 4 mm of inner diameter (6 mm outer diameter) to maintain flow rate.