6

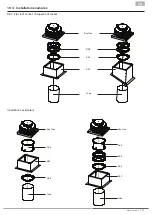

| DHA...EC CP 20 / ...EC O CP S

EN

Installation, operating and maintenance instructions

4. ADHERE TO THE FOLLOWING INSTRUCTIONS

4.1. General instructions

■

Persons who assemble, operate, disassemble or maintain our devices must not be under the influence of alcohol,

drugs or pharmaceuticals that may affect perception and responsiveness.

■

Responsibilities for the operation, maintenance and regulation of the product should be clearly determined and

observed so that there can be no unclear areas of responsibility with regard to safety.

4.2. Indications assembly

■

Disconnect all of the product‘s poles from the mains before installing the product or connecting or removing plugs.

Make sure that the product cannot be switched back on again.

■

Lay cables and lines so that they cannot be damaged and no one can trip over them.

■

Information signs must not be changed or removed.

4.3. Indications Commissioning

■

Make sure that all electrical connections are either used or covered. Commission the product only if it is installed

completely.

■

The power switch must always be fully functional and easy accessible!

■

Only authorized personnel is allowed to operate the setting mechanisms of the components or parts, under the

provision that the system is used as intended.

■

In an emergency, or if there is a fault, or other irregularities, switch the equipment off and make sure it cannot be

switched back on again.

■

The technical data given on the rating plate must not be exceeded.

4.4. Indications during operation

5. PRODUCT INFORMATION

Description:

■

Roof fan with constant pressure control

■

The temperature of the conveying medium of the individual types can be found in the technical data

■

Horizontal discharge

■

Backward curved radial impeller

■

Motor inside the airflow

■

Integrated thermal motor monitoring

■

Power switch integrated

■

Outdoor installation over heated rooms

■

Installation position vertical

■

Snow load class 0

■

Connection flange dimensions according to DIN 24154R3

■

The housing is made of plastic

■

Electronically commutated (EC) external rotor motor.

■

The roof fan with constant pressure control is used in ventilation sistems to maintain a constant set pressure level.

■

The constant pressure control is integrated in the air handling unit housing. It controls the fan speed to reach and

keep the set-point of the differential pressure constant.