3

LRBK-FIX

5

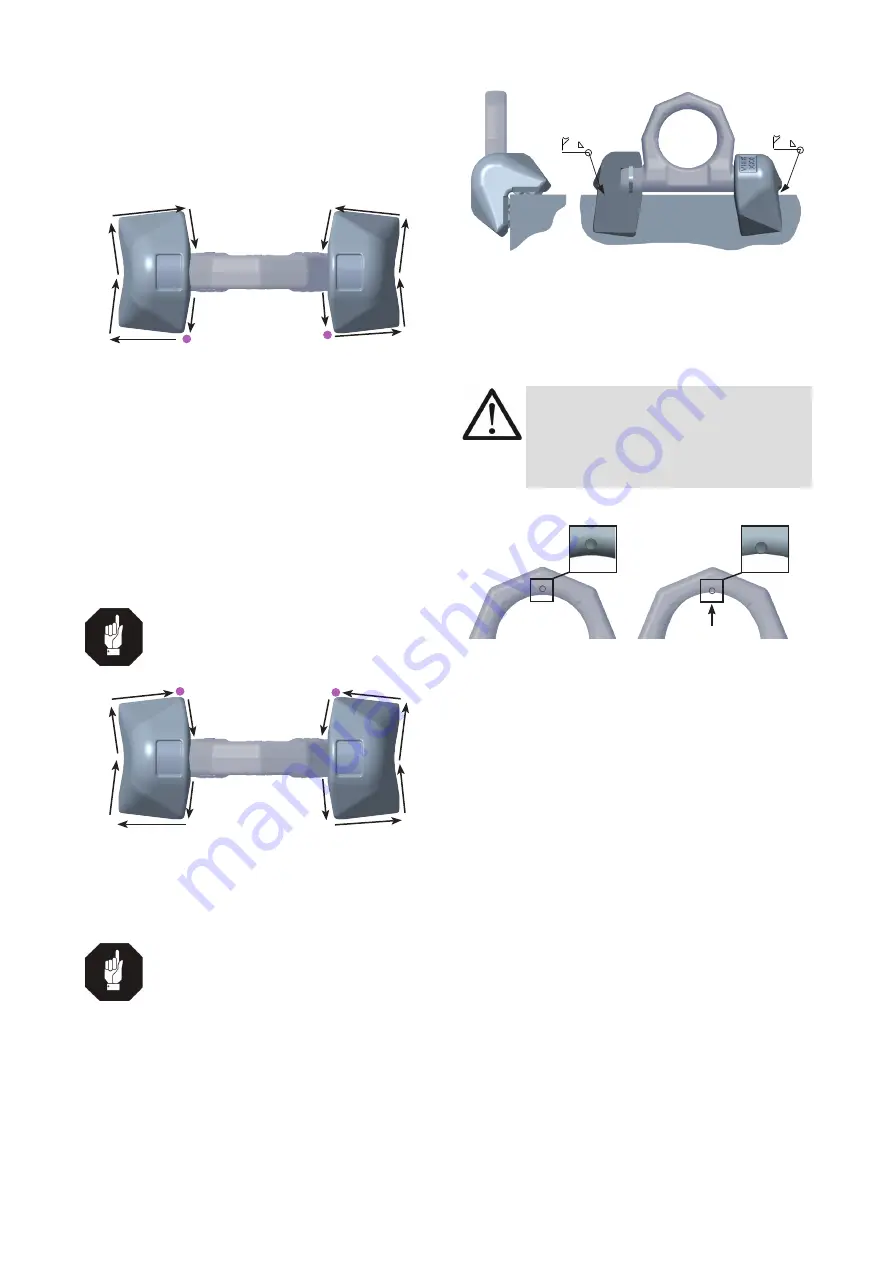

Begin at starting point S1 and weld subsequently the

sections 1-4 (

Pic. 1

).

6

Then weld the opposite side identically (starting point

S2 and chapter 5-8).

7

Afterwards close the rot pass at the inside areas (chapter

9-10 and 11-12).

S1

1

2

3

4

S2

11

12

9

8

7

6

5

10

Pic. 1: Welding sequence of the root run

(S=Starting point)

8

Finally please let the parts cool down.

9

Remove any welding mistakes and dirt at the root weld

before applying the cover weld seams.

10

Subsequently please weld the closure welds.

Start at the inside. The described welding sequences

must be observed compulsive. Chose type and dimen

-

sion of weld seam from

Pic. 3

and

Table 2

.

11

Begin at starting point S3 and weld subsequently the

chapters 1-6 (

Pic. 2

)

12

Please weld then the opposite side identically. (tarting

point S4 and chapter 7-12)

HINT

Please adhere the requested weld seam thick-

ness in any cases. Any change can result in a

malfulction of the ring latch.

S4

11

10

9

8

S3

7

12

1

2

3

4

5

6

Pic. 2: equence of closure welding

(S=Starting point)

13

Please check by a competent person after welding the

ongoing usage of the weld-on lashing point (see chapter

4 Inspection / Repair / Disposal

).

HINT

By the position of the weld-seam (HY-weld

circumferential) the following requirements will

be observed: DIN 18800 steel constructions

requires: at outdoor buildings or when strong

corrosion must be expected weld seams must

be carried out as continuous fillet weld seams.

+

+

Pic. 3: weld seam

3.4 User instruction

• Check frequently and before each initial operation the

whole lashing point in regard of linger ability as a lashing

mean, regarding corrosion, wear, deformation etc. (see

chapter

4 Inspection / Repair / Disposal

).

ATTENTION

Wrong positioned or damaged weld-on lashing

points as well as improper use can lead to inju-

ries of persons and damage at property.

Please check all lashing points carefully before

every usage.

• Please check carefully the wear indicator markings of

the weld-on lashing point (see

Pic. 4

):

Usage permitted:

no wear marks

visible

Use prohibited:

Replacement criteria

reached.

Material all the way down to the

wear lenses has gone.

Pic. 4: Wear indicators

• Please note that the lashing mean must be free moveab

-

le in the LRBK-FIX. When lashing means (f.e. lashing

chain) are hinged or unhinged, no pinching, shearing or

joint spots must occure during the handling.

• Avoid damage of lashing means resulting from sharp

edges.

• Lashing points must not be used for lifting loads.