27

COMPILER TECO/ATI

ENDORSED

DATE

29.02.2004

REG. CODE

1-5302-633

MODEL N°

51074

DATE OF ISSUE

02-04

REVISION

00

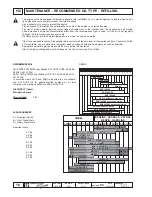

XI

36

37

38

39

D

1

2

9

7

5

3

4

6

8

10

G

F

E

B

C

A

H

L

I

M

O

P

N

0,24

5

0,25

INJECTION EQUIPMENT

Number

of holes

Diameter of steel

wire (mm)

Diameter

of holes (mm)

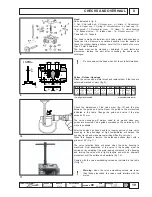

2. Mount the injector on the test bench (code

00365R0430

, fig. 40).

Disconnect the pressure gauge and rapidly operate the lever.

The nozzle must make the characteristic "trilling" sound and

inject with a good atomizing action.

3. Connect the pressure gauge. Slowly depress the level in a

continuous way until injection occurs.

The injector needle must "open" at the pressure of 230 to 238

bar. Vary the washer shims (N° 5 fig. 38) to calibrate in the

correct way.

4.

Leak test:

operate the test bench lever until the gauge pointer

is 20 Kg/cm² below the injection pressure value. Nozzle

tightness is good if no fuel comes out within 10 sec.

5.

Checking for leaks on the nozzle return phase:

operate the

test bench lever until the gauge pointer is 20 Kg/cm² below the

injection pressure value. Release the lever and

Leak test

Plug the fuel return union and let air in through the fuelling union at

a pressure of

6 Kg/cm²

. Fully immerse the pump in a receptacle

containing diesel fuel for about 50 - 60 seconds (fig. 37) and make

sure that no bubbles appear.

NOTE: the position of the pump adjuster sleeve is of no importance

for this test.

Injector

Details of fig. 38:

1. Filter - 2. Fuel inlet union - 3. Fuel return union - 4. Nozzle holder

- 5. Calibration washer - 6. Spring - 7. Pressure rod - 8. Spacer - 9.

Nozzle - 10. Ring nut.

Injector inspection and calibration

1. Clean the nozzle holes with a thin steel wire (fig. 39) with the

following diameters:

5. Insert the adjuster sleeve unit and plunger (L) into the pump

casing (A), making sure that the helical profile is directed on a

level with the return union with ball.

6. Fit in the adjuster block (M), matching the reference marks

applied during the demounting phase.

7. Tighten the plug (N) to a

0.5 to 0.6 Nm

torque, locking it in place

with Loctite 290.

8. Insert the spring (O) and lower cap (P).

9. Compress the tappets in the various operating positions to

check that the adjuster sleeve (L) slides perfectly. Resistance

or jamming will make the engine to hunt during operation.