36

COMPILER TECO/ATI

ENDORSED

DATE

29.02.2004

REG. CODE

1-5302-633

MODEL N°

51074

DATE OF ISSUE

02-04

REVISION

00

XIII

TOP

68

69

71

70

0,7 ÷ 0,8 mm

2,2 ÷ 2,7 mm

0,00 ÷ 0,10

0,10 ÷ 0,20

0,20 ÷ 0,30

0,30 ÷ 0,40

0,8

0,9

1,0

1,1

ENGINE ASSEMBLY

Head

Before fixing the head to the cylinder, fit the injector into its housing

and, after having temporarily fixed it, check that the distance the

nozzle projects from the surface of the head by (fig. 72):

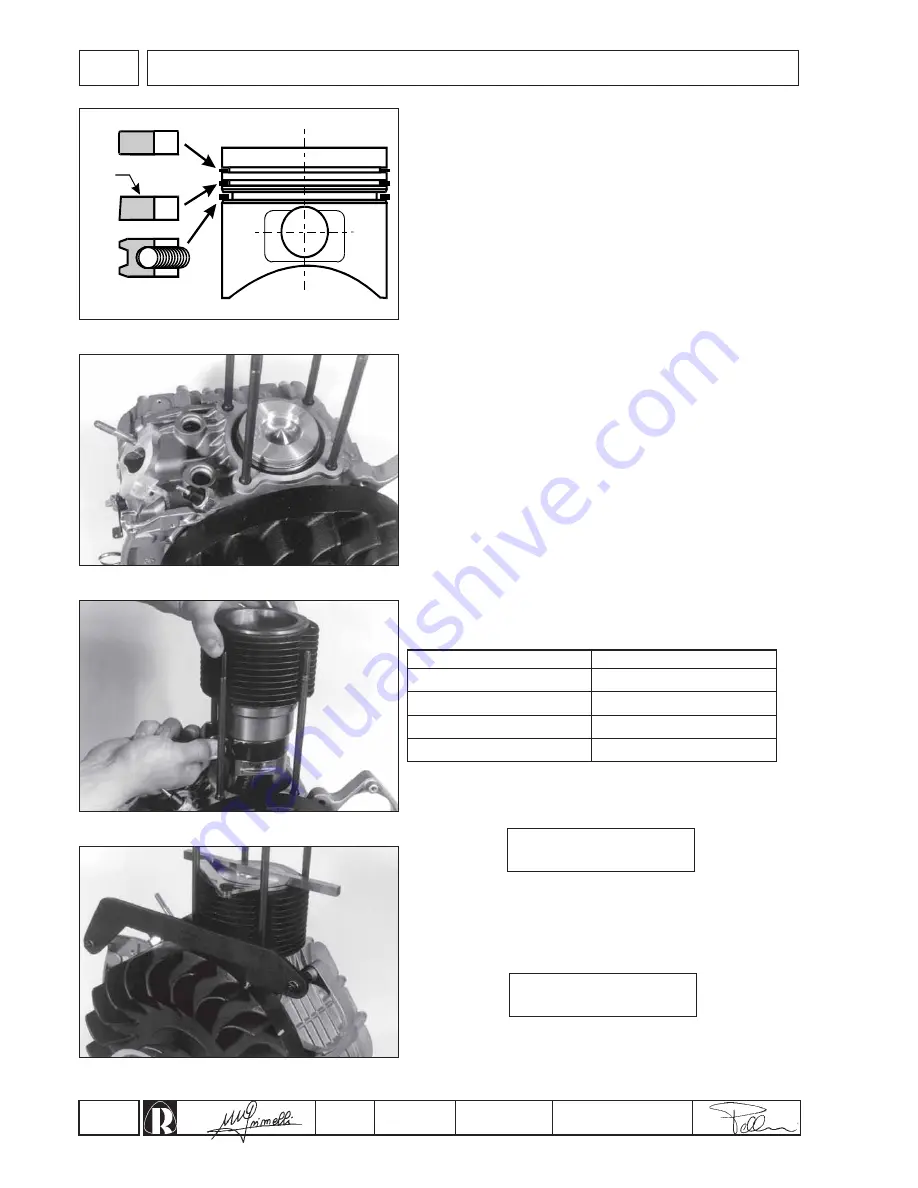

Cylinder

Insert the cylinder into the engine casing after having inserted the

0.3 mm thick seal.

before mounting, turn the rings through 120°, one in relation to the

other, with the first compression ring pointing with its ends on a

level with the pin axis.

There is a chamfer to allow ring insertion on the lower side of the

cylinder. The operation is simplified by using a normal ring

mounting tool code

00365R0770

as indicated in fig. 70.

Move the piston to TDC (top dead center) and check that the mark

stamped on the flywheel corresponds to the reference pointer of the

tool code

00366R0240

(fig. 75).

To obtain the correct clearance, use a head seal of adequate

thickness:

1. check the piston projection as shown in fig. 71

2. Choose the seal as indicated in the following table

NOTE: The distance between piston crown and the corresponding

head surface must be:

regulate by placing copper washers between the injector and the

bearing surface on the head.

Consult page 19 and 20 for the relative inspections and overhauls.

Piston

Mount the rings on the piston (fig. 68) in the following order:

1. chromium plated compression retention ring (stamped

trademark pointing upwards)

2. tapering retention ring (stamped word TOP pointing upwards)

3. oil scraper ring (stamped trademark pointing upwards)

Position the piston so that the central axis of the combustion

chamber is aligned with the injector (fig. 69). Connect the piston to

the connecting rod, slightly pressing with the hand on the pin.

Piston projection (mm)

Seal thickness (mm)