23

Chapter 7 Equipment Maintenance

7.1 Common Equipment Maintenance Process

1. Regular maintenance of tube

When the tube is not used for a long time, please empty the liquid in the tube in time, open the

protective lock on the pump head and loosen the pump tube.

2. Check tube connectors regularly

Regularly check whether the tube connector is loose or damaged. If it is abnormal, it must be

replaced in time

3. Regular or irregular calibration

Recalibration is necessary after the tube is replaced or loosened.

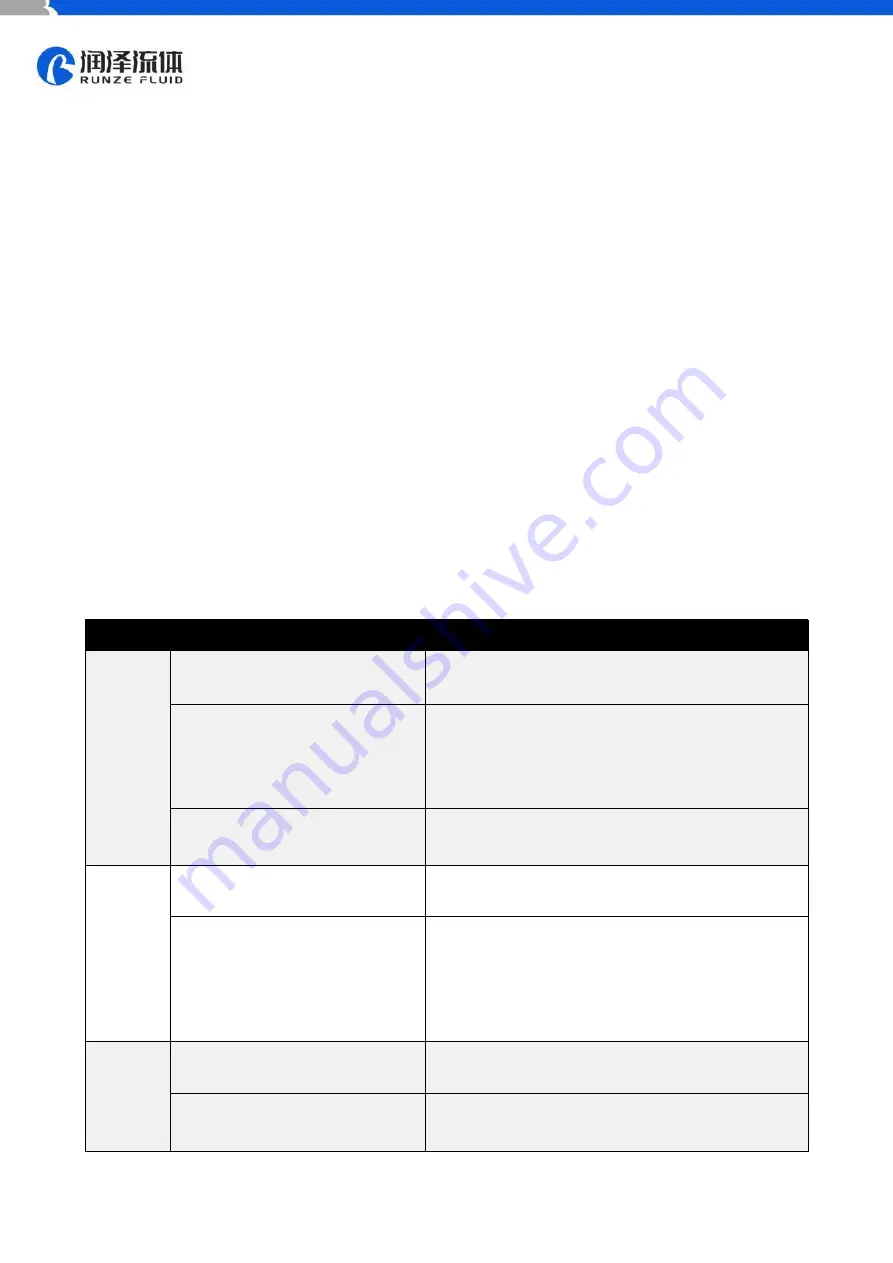

7.2 Common Problems and Solutions

Problem

Problem description

Solution

The

backlight

is not on.

The value of "backlight time" in

"settings" is set to 0

Increase the value of "backlight time" in "settings".

Failure of backlight hardware or

backlight power control part

The backlight problem does not affect the normal use

of the pump, and the backlight function is generally

used in a dark environment. If it is a hardware failure, it

is recommended to return to the factory for repair.

Value of “Contrast” in

“settings” is set to 1

Increase the value of “Contrast” in “settings”

Burred

LCD

screen

There are large disturbance

sources nearby

When the instrument works, try to keep it away from

the disturbance source

The position of data refreshed to

LCD screen is out of order due to

unknown reasons

The wrong display of the screen does not affect the

normal operation of the motor control. If the motor is

running, press the "ON/OFF" to stop the motor. On

the standby interface, press the "HOME" for five times

to refresh the screen display again.

Fan does

not rotate

The fan is too dusty and blocked

After the power is turned off, use a soft brush to

remove dust

The fan is broken or the fan power

supply is not in good contact

Return to factory for repair