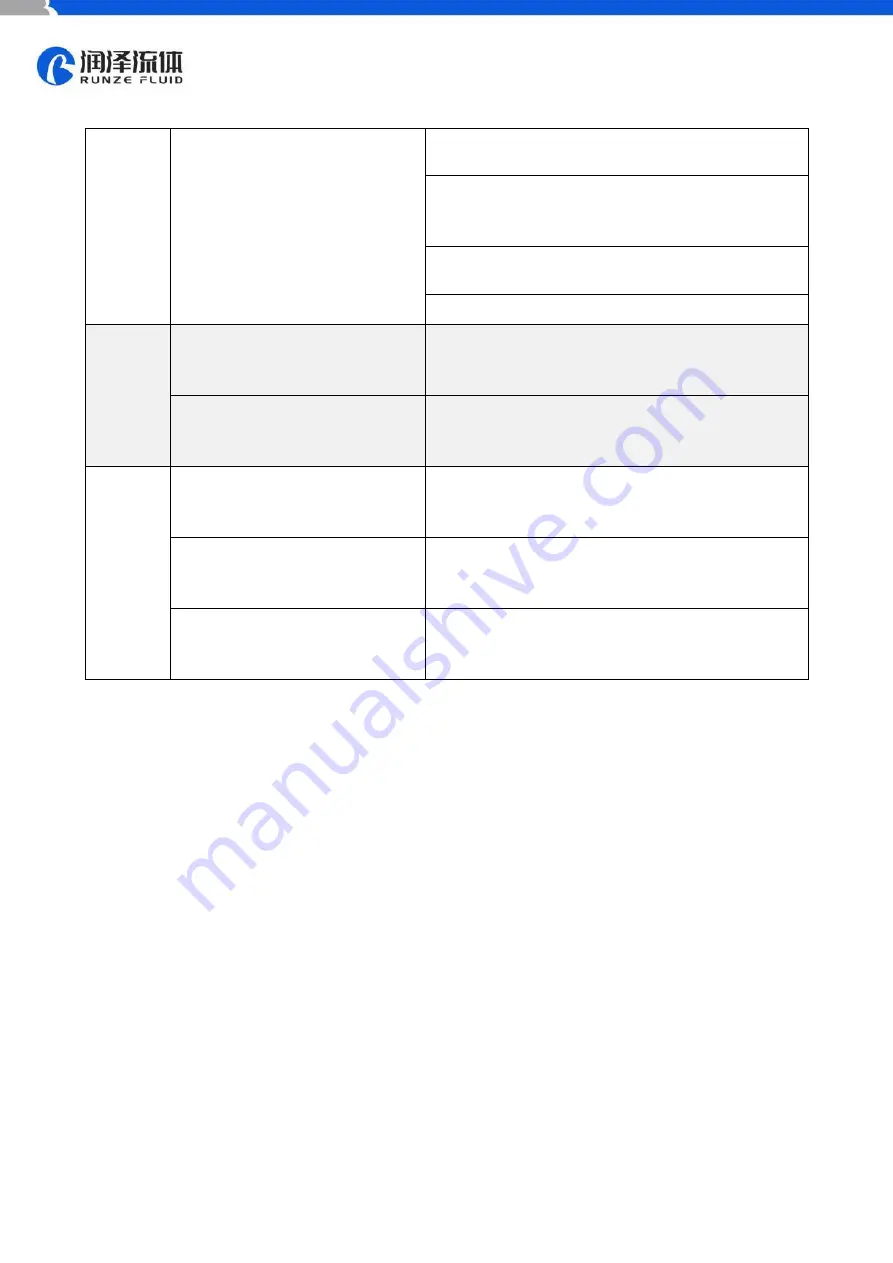

24

Motor

does not

rotate

The screen shows that the motor

works. In fact, the motor does not

rotate.

Check whether the pump body joint is loose and

reliable.

Check whether the current code in “settings” is too

small. Set the current code consistent with the

product.

The motor connecting wire is loose and return to the

factory for repair.

Power wire is loose and return to factory for repair.

Motor

stalled

The original pump head / tube can

run at a certain speed, but the new

pump head / tube cannot run.

The new pump head / tube should be run for one or

two minutes at a lower speed.

The maximum speed of the motor

suitable for the pump head / tube

is exceeded.

Please refer to the above operation curve to select the

reasonable speed corresponding to the pump head /

tube.

Inaccurat

e flow or

liquid

volume

There is a big difference in the

liquid volume or flow rate after

replacing the tube.

Recalibrate and input accurate calibrated parameters.

You can take the mean value after multiple

calibrations, and then enter the mean value.

The tube has been used for a long

time and its resilience has

decreased

Replace the tube.

Accuracy requirement is not

appropriate.

The flow rate / speed / tube diameter are inversely

proportional to the accuracy. Try to use smaller

diameter tube.