9

and input the calibration result. The specific calibration process is as follows:

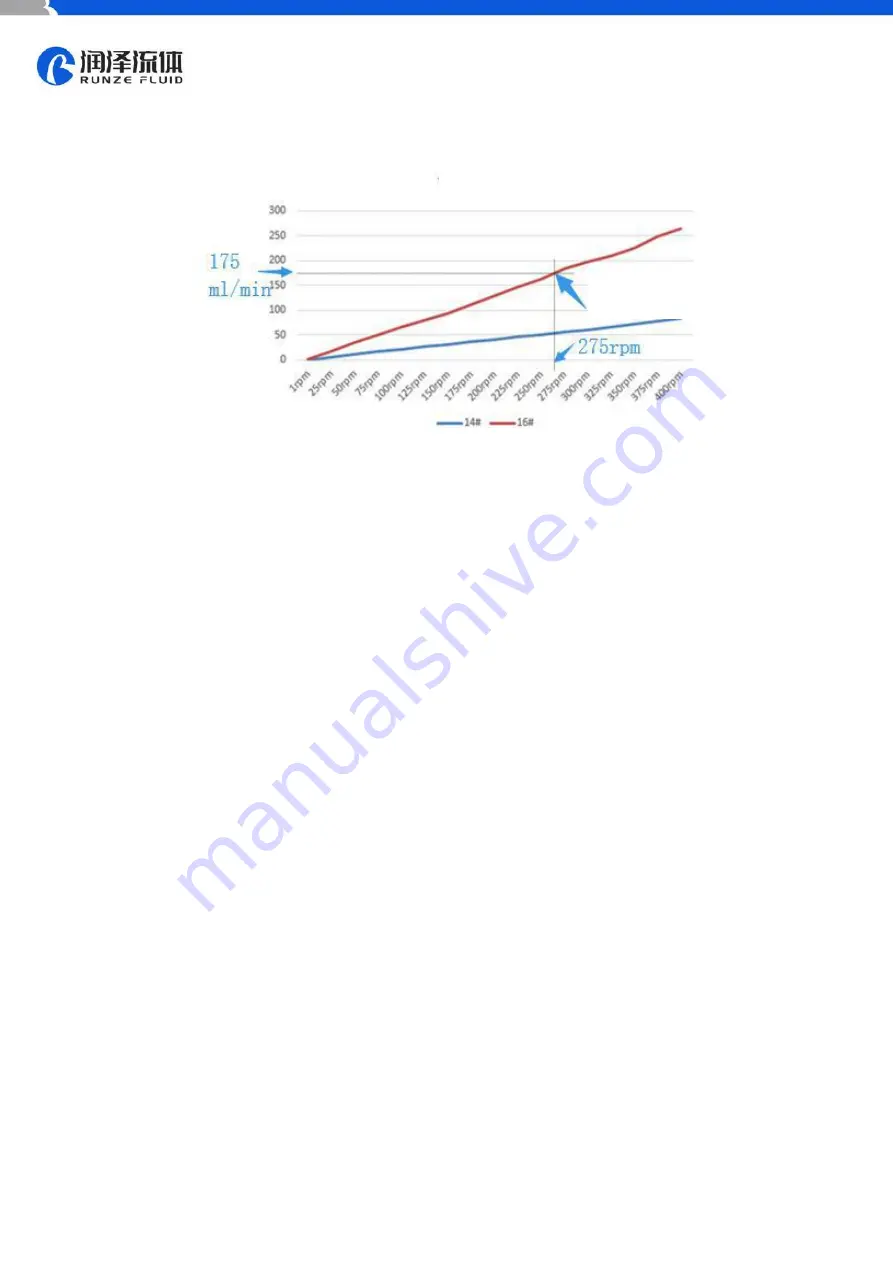

Figure 3-2-1

Use of flow curve table

(1) Determine calibration speed. According to the flow rate you need, query the flow curve of the

corresponding pump head / tube (Chapter 6 flow curve) to obtain the approximate calibration speed.

Take YZ1515X-6 wheel and 16# tube as an example. If you need a flow rate of 175ml / min, find the

approximate position of 175ml / min on the longitudinal axis, make a horizontal line intersecting with

the red line of the flow curve of the 16# tube, make a vertical line from the intersection point to the

horizontal axis, and the intersection point with the horizontal axis is the calibrated target speed (about

275rpm).

(2) Edit calibration parameters. On the calibration editing interface, input the calibration speed

and calibration time, set the liquid volume to 0, and press the "Enter" key to save.

(3) Perform calibration process. Press the "CW/CCW" key, select the required steering direction,

pre fill the tube, and empty the liquid in the receiving container. In the calibration standby interface,

press the "ON/OFF" to start the peristaltic pump. After running the "calibration time", the dispensed

liquid volume is the " volume" of this calibration. Use the measuring cup to read the milliliter of

dispensed liquid.

(4) Input calibration data: after calibration, press the "Edit" to input the above calibration data (ml

of liquid volume), and press "Enter" to save. After that, the system will automatically return to the main

interface. When saving, if it displays "maximum flow overflow default value!", you need to check the

calibration process again to see if the test value is wrong.

Note:

The calibration time of the pump is 60 seconds by default. You can also extend it

Intersection point

YZ1515X-6 rollers