6

To turn the polisher off, release the lever or, if locked in ON

position, push the lever to release the lock button.

ELECTRONIC SPEED CONTROL

The polisher electronic speed control supply the following fea-

tures.

Speed compensation

In case of overloading the polisher, the electronic speed control

will compensate and maintain the selected speed till a safe level.

Exceeding this overload level may result in strong vibrations and

tool overtemperature.

Starting acceleration ramp

To avoid kickback effect and compound splattering, the

electronic speed control always supply a smooth starting

acceleration ramp when the tool is turned on.

Accidental re-start protection

In case of a sudden lack of main power supply, the electronic

speed control prevents the re-start after the power supply

restoring if the main switch is turned on. The polisher must be

turned off and on again pushing the lever of the switch (2)

toward the body of the tool.

OPERATION

INTENDED USE

MOTOR

Be sure your power supply agrees with the voltage marked on

the nameplate. 120 Volts AC 60Hz means alternating current

only. Voltage decrease of more than 10% will cause loss of

power and overheating.

PARTS OF THE TOOL

ON/OFF SWITCH

To turn the polisher on, push the lever of the switch (2) towards

the body of the tool; if the polisher is to be locked in ON position,

press button ( ) at the same time and keep it pressed while

releasing lever, thus locking the switch.

WARNING: To reduce the risk of injury, make sure the

polisher is not resting on the workpiece when the switch

is turned on.

WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and

removing accessories, before adjusting or when making

repairs. Be sure the switch is in the “OFF” position. An

accidental start-up can cause injury

WARNING: Never modify any parts of the power tool.

Damage or personal injury could result.

MODEL

LK900E

165

150

250÷560

2,70

•

VOLTAGE

120 V AC - 60 Hz

ABSORBED CURRENT

TECHNICAL DATA

ENGLISH

LK900E

5

900

7 A

/ II

Ø POLISHING FOAM mm

Ø BACKING PAD mm

Ø ORBIT mm

POWER

R.P.M.

WEIGHT

ELECTRONIC SPEED CONTROL

INSULATION CLASS

7

5

2

6

3

1

4

8

OFF

ON

Speed Adjustment

ON

OFF

6

3

2

1

5

4

7

8

9

9

INTENDED USE

The LH19E heavy-duty polishers is designed for polishing painted

or unfinished metal, fiberglass, and composite surfaces in

professional applications. Common examples of use include but

are not limited to: auto/marine/RV/motorcycle detailing and finish

correction, boat construction and repair, and metal finishing.

Do not use in the presence of flammable liquids or gases.

Do not let children come into contact with the tool. Supervision

is required when inexperienced operators use this tool.

MOTOR

Be sure your power supply agrees with the voltage marked on

the nameplate. 120 Volts AC 60Hz means alternating current

only. Voltage decrease of more than 10% will cause loss of

power and overheating.

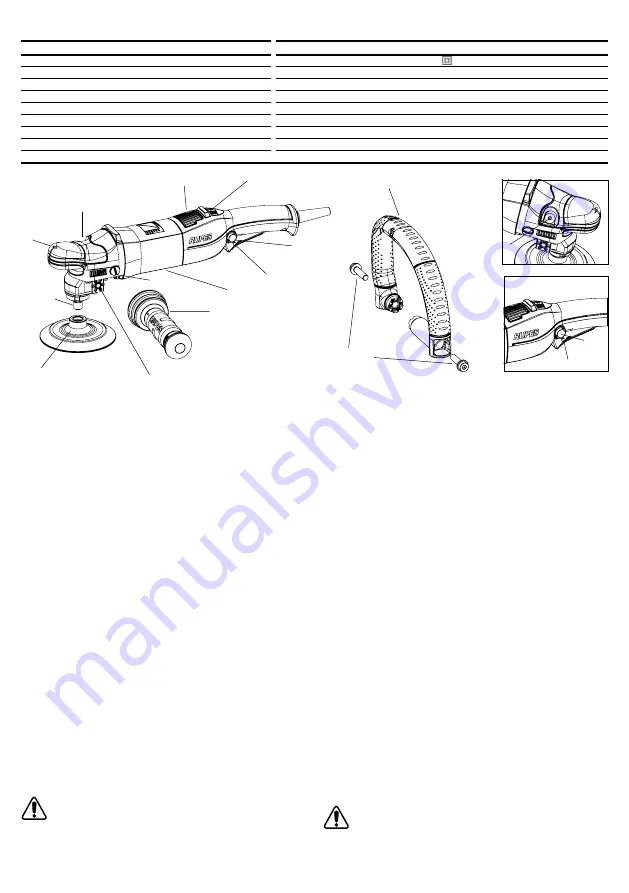

PARTS OF THE TOOL

1 - Identification plate

2 - ON/OFF switch

3 - Electronic speed control

4 - Spindle shaft

5 - Handle site

6 - Cap

7 - Plate pad

8 - Srews

9 - Switch locking botton

10 - Botton lock

11 - Ventilator motor

12 - Handle

13 - Scews for handle

14 - Locking screws

ON/OFF SWITCH

WARNING: To reduce the risk of injury, make sure the

polisher is not resting on the workpiece when the switch

is turned on.

To turn the polisher on, push the lever of the switch (2) towards

the body of the tool; if the polisher is to be locked in ON position,

press button (9) at the same time and keep it pressed while rele-

asing lever, thus locking the switch.

To turn the polisher off, release the lever or, if locked in ON

position, push the lever to release the lock button.

ELECTRONIC SPEED CONTROL

The polisher electronic speed control supply the following fe-

atures.

Speed Adjustment

The speed can be adjusted in two ways: by means of the variable

actuation switch (2), by means of the adjustment wheel fitted on

the upper part of the machine (3).

Adjustment by means of the wheel (3) affects the adjustment

made using the variable actuation switch (2), determining the ma-

ximum speed of the motor.

The speed must be selected according to the characteristics of the

pads and those of the material to be machined.

Speed compensation

In case of overloading the polisher, the electronic speed control

will compensate and maintain the selected speed till a safe level.

Exceeding this overload level may result in strong vibrations

and tool overtemperature.

Starting acceleration ramp

To avoid kickback effect and compound splattering, the electro-

nic speed control always supply a smooth starting acceleration

ramp when the tool is turned on.

Accidental re-start protection

In case of a sudden lack of main power supply, the electro-

nic speed control prevents the re-start after the power supply

restoring if the main switch is turned on. The polisher must

be turned off and on again pushing the lever of the switch (2)

toward the body of the tool.

OPERATION

WARNING: To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs. Be sure the switch is in the “OFF” posi-

tion. An accidental start-up can cause injury

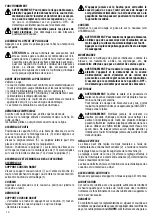

6

2

9

3

11

1

5

8

14

4

10

7

LH19E

12 (

optional)

13 (

optional)

TYPE

INSULATION CLASS

POWER

W

n NOMINAL RPM

/min

ELECTRONIC SPEED CONTROL

BUFFER PAD AND BUFFER DIAMETER MAX

SPINDLE THREAD

WEIGHT Kg

VOLTAGE

ABSORBED CURRENT

LH19E

/ II

1200

450 ÷ 1700

YES

200

5/8’’

2,25

120 V AC – 60Hz

8.5 A

10

2

9

Summary of Contents for LH19E

Page 2: ......