7 - 6

Specification

noiSe levelS

►

The tractor is approved in accordance with the applicable EC Directives.

to avoid increased noise levels proceed as follows:

After maintenance operations or repairs refit all the sound-deadening panels and materials correctly

Do not make changes to the tractor that may lead to an increase in noise emissions.

Beware of any anomalous noise or vibration if you notice anomalous noise or vibration, park the tractor in a safe position

and perform the stopping procedure. Inform maintenance personnel of the situation. Avoid prolonged operation.

Reference standards for the measurement of noise levels:

The maximum driver-perceived noise level, with the engine at normal operating temperature and measured in accordance

with the test method described in the European Directive 009/76EC

The maximum noise level measured with the tractor in motion and the tractor stationary, measured in accordance

with the method described in European directive 009/63/EC.

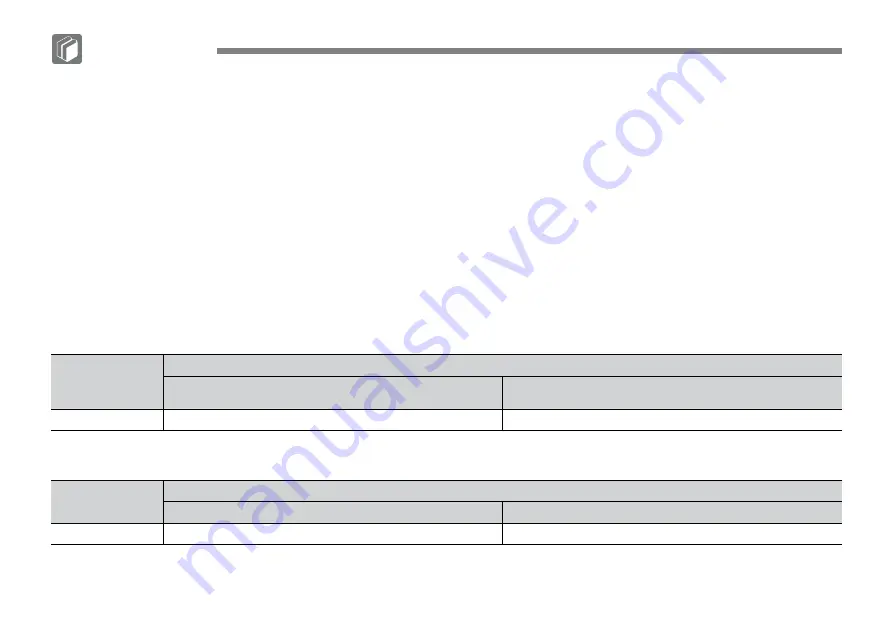

Model

noiSe levelS

Maximum noise level in CAB with Doors open

(Roof hatch and front And rears windows open), db(A) Maximum noise level in CAB with doors closed, db(A)

RK74PSC

81.5

8

Model

noiSe levelS

Maximum external noise level With tractor moving, db(A) Maximum external noise level With tractor stationary, db(A)

RK74PSC

80

77.5

Summary of Contents for RK74 Power Shuttle

Page 7: ...MEMO ...

Page 44: ...2 25 2 SAFETYPRECAUTIONS min km h 30 0 ON ON OFF OFF R74O204B ...

Page 45: ...2 26 SAFETYPRECAUTIONS T75O205B ...

Page 47: ...MEMO SAFETYPRECAUTIONS ...

Page 80: ...4 4 OPERATION Ib h aa T65O402a ...

Page 83: ...MEMO OPERATION ...

Page 96: ...5 13 5 MAINTENANCE 7 BLEEDING THE FUEL SYSTEM T75O518A ...

Page 142: ...Specification 1 SPECIFICATIONS 7 2 7 ...

Page 149: ...MEMO SPECIFICATION ...

Page 163: ...9 APPENDIX DATE TRACTOR HOURS NATURE TYPE OF REPAIR SERVICE CARRIED OUT 4 SERVICE RECORD ...

Page 171: ...MEMO APPENDIX ...

Page 172: ...INDEX 1 INDEX 10 2 10 ...

Page 180: ...11 WARRANTY 1 ENGINE WARRANTIES 11 2 2 EMISSION SYSTEM WARRANTY 11 5 3 RK WARRANTY 11 13 ...