REVT-05ERV 37

Flue Passageway and Flue box

1. Remove combustion air inducer as described in

Steps 1-3

above.

2.

Remove flue box cover and clean with a wire brush

as required.

3. Clean tubes with wire brush.

4. Follow

Steps 5-6

above.

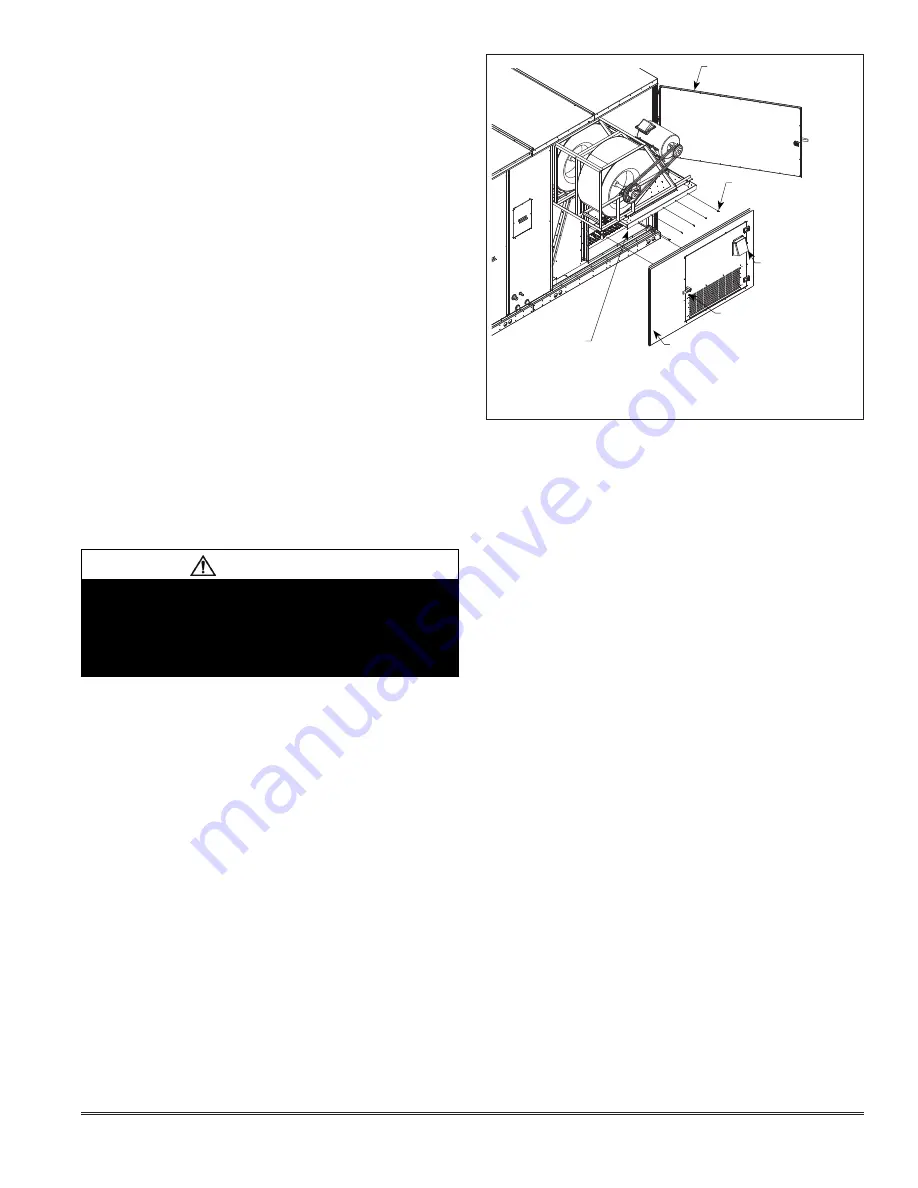

F. BLOWER COMPONENTS

Blower Access

- The dual supply blower assembly in the

EVT-10 and EVT-12 is designed to slide-out for servicing

as shown in

Figure 36

.

Lubrication

- All motors are lubricated at the factory - no

further lubrication is required. Blower shaft bearings are

pre-lubricated; however, for extended bearing life, re-

lubricate at least once every two years with a lithium base

grease, such as Alvania 3 (Shell Oil), Chevron BRB@

(Standard Oil), or Regal AFB2 (Texas Oil).

Use a hand grease gun for re-lubrication and add only

enough grease to purge through the bearings so that a

bead of grease appears at the seal lip contacts.

Under normal operating conditions, the combustion air

inducer wheel should be checked and cleaned prior to

the heating season. However, it should be examined

periodically during the heating season to establish an

ideal cleaning schedule. With power supply disconnected,

the condition of the inducer wheel can be determined by

removing the Flue Vent (

Figure 19

) and looking through

the discharge opening.

Clean the combustion air inducer as follows:

1.

Shut off power supply and gas to unit.

2. Disconnect pressure switch air tubing from combustion

air inducer port.

3.

Remove and retain screws securing flue vent to

the inducer. Remove and retain screws securing

combustion air inducer to the flue box.

See Figure

19.

4. Clean inducer wheel blades with a small brush and

wipe off any dust from housing. Clean accumulated

dust from front of flue box cover.

At this point the flue passageway and flue box may be

cleaned as described below.

5. Reassemble the unit. It is recommended that the

combustion air inducer gasket be replaced during

reassembly.

6. Clean combustion air inlet louvers on heat access

door using a small brush.

WARNING

The State of California has determined that this

product may contain or produce a chemical or

chemicals, in very low doses, which may cause

serious illness or death. It may also cause cancer,

birth defects, or reproductive harm.

FIGURE 36 - SLIDE-OUT BLOWER ASSEMBLY

BLOWER ACCESS DOOR

REMOVE SCREWS TO SLIDE

BLOWER ASSEMBLY OUT

OF UNIT

FLUE VENT COVER

DISENGAGE HANDLE BEFORE

ATTEMPTING TO REMOVE

STATIONARY PANEL

REMOVE STATIONARY PANEL BEFORE

ATTEMPTING TO SLIDING BLOWER

ASSEMBLY

BLOWER ASSEMBLY

SLIDING BASE

For EVT-10 & EVT-12 Units Only: Blower assembly

slides out to provide rear-blower service access.

Supply / Exhaust Blower Wheels

Fan Belts

- Check on a regular basis for wear, tension,

alignment, and dirt accumulation. Premature or frequent

belt failures can be caused by improper belt tension or

misaligned sheaves. Abnormally high belt tension or drive

misalignment will cause excessive bearing loads and may

result in failure of the fan and/or motor bearings. Loose

belts will cause squealing on start-up, excessive belt

flutter, slippage, and overheated sheaves. Both loose

and tight belts can cause fan vibration.

When replacing belts on multiple groove drives, all belts

must be changed in matched sets to provide uniform drive

loading. Do not pry belts on or off the sheave. Loosen

belt tension until belts can be removed by simply lifting

off of the sheave. Belt dressing should never be used.

Never install new belts on worn sheaves. If the sheaves

have grooves worn in them, they must be replaced before

new belts are installed. Determine proper belt tension as

shown in

Figure 17

.

Fan Motors

- All motors use pre-lubricated, sealed

bearings that require no further lubrication. Motor

maintenance is generally limited to inspection and

cleaning. Cleaning should be limited to exterior surfaces

only. Removing dust and grease buildup on motor

housing aids motor cooling. Never wash-down motor with

high pressure spray.

Fan Wheels

- Require little attention when moving clean

air. Occasionally oil and dust may accumulate causing

imbalance. When this occurs the wheel and housing

should be cleaned to assure smooth and safe operation.

Inspect fan wheel and housing for fatigue cracks,

corrosion and wear.

Summary of Contents for ENERVENT+ EVT-09 Series

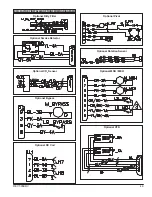

Page 30: ...30 REVT 05ERV UNIT WIRING DIAGRAM ...

Page 31: ...REVT 05ERV 31 UNIT WIRING DIAGRAM CONTINUED ...

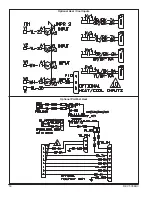

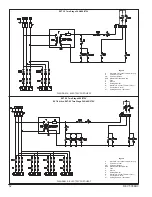

Page 47: ...REVT 05ERV 47 UNIT WIRING DIAGRAM XVIII WIRING DIAGRAMS ...

Page 48: ...48 REVT 05ERV UNIT WIRING DIAGRAM CONTINUED ...

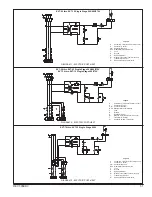

Page 50: ...50 REVT 05ERV Optional Heat Cool Inputs Optional Pre Post Heat ...

Page 57: ...REVT 05ERV 57 DIAGRAM 15 5 1 MODULATION GAS POST HEAT DIAGRAM 14 2 STAGE GAS POST HEAT ...