38 REVT-05ERV

XVII - VFD FACTORY SET POINTS

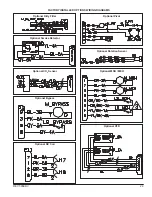

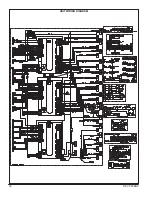

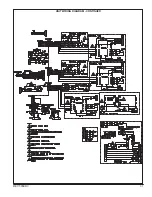

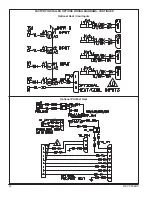

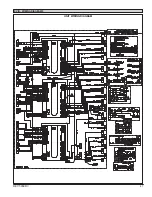

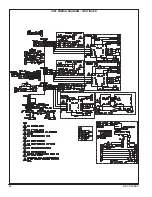

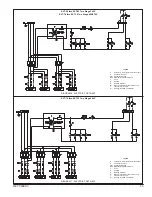

XVIII - WIRING DIAGRAMS, PRE- AND POST-HEAT

Fan Bearings

- Enervent units have pillow block bearings

that require proper lubrication at regular intervals to

extent bearing life and to prevent premature failure.

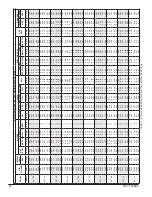

Table 11

shows the recommended lubrication schedule

under normal operating conditions. If unusual conditions

exist; i.e., below 32°F or above 200°F, with moisture

or contaminants present, more frequent lubrication is

required.

Be careful not to unseat the seal by over lubricating or

using excessive pressure. With the unit running, add

grease very slowly with a manual grease gun until a

slight bead forms at the seal. As a guide fill 30 to 60% of

available space within the bearing and its housing. Use

a high quality lithium based grease that conforms to NLGI

Grade 2.

In addition to lubricating the bearings at specified intervals,

set screws in the bearing collars should be checked for

tightness. A bearing collar which has loosened will cause

premature failure of the fan shaft. Fasteners attaching

the bearings to the drive frame should also be checked.

BLOWER BEARING LUBRICATION SCHEDULE

BLOWER

SHAFT DIA (in.)

RPM

1.00 to 1.50

1.75 to 2.00

< 500

6 mo

6 mo

500-1000

6 mo

5 mo

1000-1500

5 mo

4 mo

1500-2000

4 mo

3 mo

2000-2500

4mo

2 mo

2500-3000

3 mo

1 mo

3000-3500

2 mo

1 mo

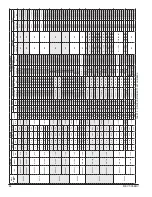

VFD STARTUP WITH BASIC PROGRAM

PARAMETER

DESCRIPTION

CODE

P031

Motor Nameplate Amps

Based on Drive Rating

P032

Motor Nameplate Hertz

60 Hz (Default)

P033

Motor Overload Current

Based on Motor FLA Rating

P034

Minimum Frequency

0.0 Hz (Default)

P035

Maximum Frequency

60.0 Hz (Default)

P036

Start Source

2-Wire

P037

Stop Mode

0-Coast (Default)

P038

Speed Reference

2 = 0-10 Volt Input

3 = 4-20 ma Input

P039

Acceleration Time

10 sec (Default)

P040

Deceleration Time

10 sec (Default)

P041

Reset to Defaults

0 = Ready/Idle (Default)

P042

Voltage Class

3 (Default)

P043

Motor Overload Retention

0 = Disabled (Default)

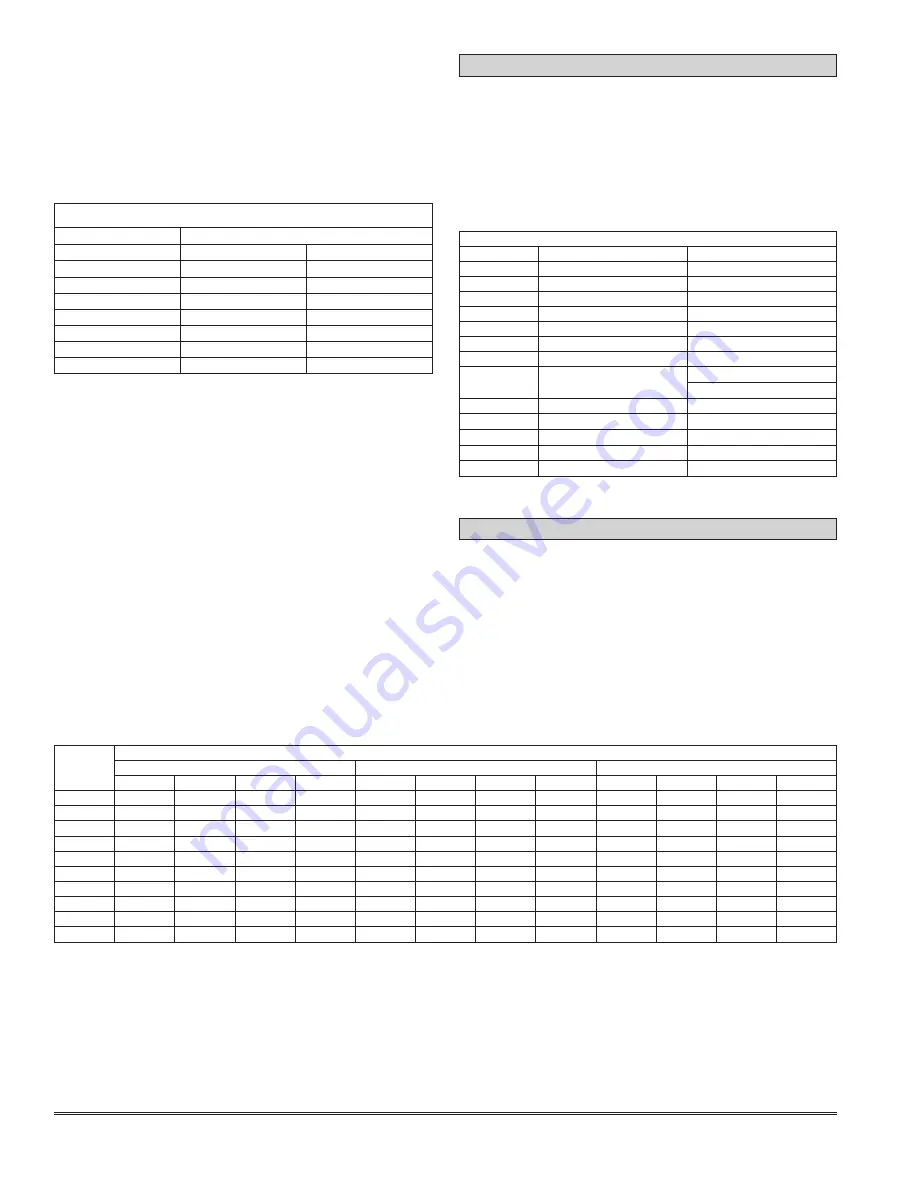

Model

WIRING DIAGRAM NUMBER -- ELECTRIC POST-HEAT

240V

480V

575V

1-STG

2-STG

3-STG

4-STG

1-STG

2-STG

3-STG

4-STG

1-STG

2-STG

3-STG

4-STG

EVT-09

1

—

—

—

1

—

—

—

1

—

—

—

EVT-19

1

4

—

—

1

4

—

—

1

4

—

—

EVT-28

2

—

—

—

2

—

—

—

2

—

—

—

EVT-36

2

6

—

—

2

5

—

—

2

5

—

—

EVT-46

2

6

—

—

2

5

—

—

2

5

—

—

EVT-62

2

6

8

—

2

5

9

—

2

5

10

—

EVT-74

3

7

—

—

2

6

—

—

2

6

—

—

EVT-88

3

7

11

—

2

6

8

—

2

6

8

—

EVT-10

3

7

11

—

2

6

8

—

2

6

8

—

EVT-12

3

7

11

12

2

6

8

13

2

6

8

13

TABLE 11 - BLOWER BEARING LUBRICATION SCHEDULE

TABLE 12 - VFD SETPOINTS

TABLE 13 - WIRING DIAGRAM INDEX - ELECTRIC POST-HEAT

Modulating Control for Fan Speed

– Variable Frequency

Drives (VFD) for the blower are factory set to receive a

0-10 VDC signal wired in the field. Most of the setpoints in

the VFD’s are factory defaults. There are a few, however,

that are changed in the factory and are shown in

Table

12.

If job specifications requires changing these set

points refer to the VFD Manufacture's manual included

with the unit.

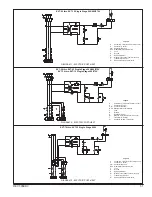

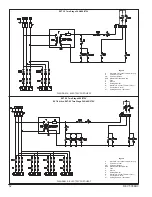

Table 13

provides a quick reference for locating a given

Electric Post-Heat diagram on

Pages 49-54

. Gas Post-

Heat can be found on

Page 55

,

Diagram 14

and Electric

Pre-Heat diagrams can be ready found on

Pages 55-56,

Diagrams 15-17.

Summary of Contents for ENERVENT+ EVT-09 Series

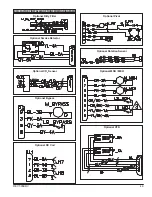

Page 30: ...30 REVT 05ERV UNIT WIRING DIAGRAM ...

Page 31: ...REVT 05ERV 31 UNIT WIRING DIAGRAM CONTINUED ...

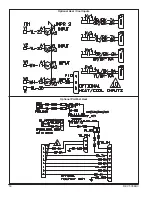

Page 47: ...REVT 05ERV 47 UNIT WIRING DIAGRAM XVIII WIRING DIAGRAMS ...

Page 48: ...48 REVT 05ERV UNIT WIRING DIAGRAM CONTINUED ...

Page 50: ...50 REVT 05ERV Optional Heat Cool Inputs Optional Pre Post Heat ...

Page 57: ...REVT 05ERV 57 DIAGRAM 15 5 1 MODULATION GAS POST HEAT DIAGRAM 14 2 STAGE GAS POST HEAT ...