4 REVT-05ERV

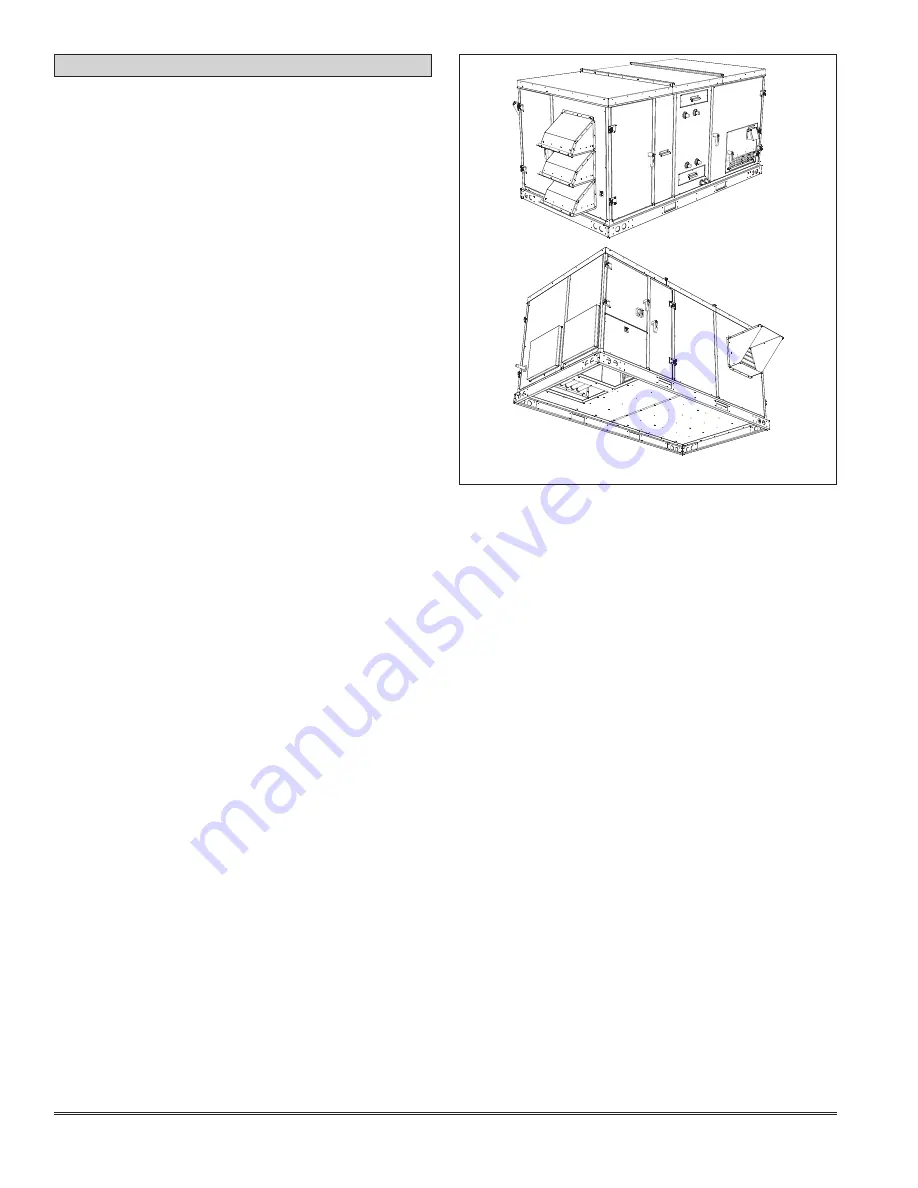

IV - FEATURES and OPTIONS (Figure 1)

A. BASIC UNIT - STANDARD FEATURES

1. BASE RAIL

- Full perimeter, reinforced, heavy-gauge

base rail with forklift slots and rigging holes maintains

structural integrity during transportation, handling,

and installation.

2. MODULAR FRAME

- Extruded aluminum Modular

Frame System adds structural strength and rigidity

to entire cabinet. Assures a square, sturdy overall

structure and frame for access doors and other

openings such as supply and return openings.

3. DOUBLE-WALL CONSTRUCTION

- All exterior

panels, plus divider panel between supply and

exhaust chambers, are double-wall construction;

which, along with multiple modular framing cross

members, adds strength and rigidity to the top and

bottom panels. Each panel has an interior core of 1

inch, R-3.6 fiberglass insulation for effective thermal

and acoustical performance.

4. ACCESS DOORS

- Hinged with tool-less, quarter-

turn latching handles that possess a "cam latch"

assuring tight air and water seal. Provide quick

access to components and protect panels and roof

from damage. Hinges and handles are made of high

strength nylon reinforced fiberglass.

5. AIRXCHANGE ERC

- Standard Energy Recovery

Cassette is an all-welded stainless steel assembly

containing a desiccant coated (enthalpy) wheel.

Desiccant used is silica gel, which has superior

moisture handling capacity in the working range

above 30% R.H., the range of greatest concern.

Patented and proprietary process permanently bonds

desiccant to surface without adhesives permitting

long life with repeated washings without loss of

effectiveness. Removable, light weight segments

make easy cleaning and replacement possible and

convenient. An AHRI Certified Component assuring

credible and reliable performance per AHRI Standard

1060.

6. SILENT-PRO® BLOWERS

- Manufactured

specifically for Ruskin Rooftop Systems by Lau

Industries to a proprietary specification. Shafts are

ground and polished steel mounted in permanently

lubricated, sealed, ball bearing pillow-block bearings

selected for a minimum life of L-10. All supply and

exhaust blowers are belt driven to allow independent

balancing of supply and exhaust airflow.

7. VIBRATION ISOLATORS

- Both the supply and the

exhaust blowers are mounted on neoprene vibration

isolators providing additional acoustical performance.

8. BLOWER MOTORS and DRIVES

- NEMA Premium

Efficient motors that exceed requirements of Energy

Policy Act of 1992. Base mount with easy adjustment

of belt tension. Mounting permits "slide-out" of motor

and adjustable mount for easy service or replacement.

All drive combinations are sized for 150% of driven

horsepower. Low, medium, and high speed drive kits

are available to achieve required CFM range. Fixed

diameter cast iron pulley on blower with adjustable

EXTERIOR VIEWS

pitch cast iron sheave on motor - laser aligned for

V-belt connection.

9. AIRFLOW CHOICE

- Available in downflow (vertical)

or horizontal supply and return airflow configuration.

10. OUTDOOR AIR HOOD

- Angled to prevent water

induction and includes 1 inch aluminum mesh mist

elimination filters. Shipped as a separate kit with

instructions for field assembly and installation.

11. EXHAUST AIR HOOD

- Shipped separately as an

assembly for field installation. Includes back draft

dampers and cover screen.

12. AIR FILTERS

- Supply and return MERV 8 (optional

MERV 11 and MERV 13 available), 2 inch pleated

filters with average dust spot efficiency of 30-35%.

13. CONTROLS

- All internal electrical components

are factory wired for single-point power connection.

Units with electric pre-heat and/or post-heat are wired

with field supplied independent power supply. All

components are UL Listed, Approved, or Recognized

where applicable and wired in compliance with

National Electric Code (NEC). Hinged external access

door to control box has an interlocking, fused NEMA

3R disconnect switch. Control box containing all

major electrical control components has removable

cover panel.

Direct Digital Controller

- Unit controls are

performed by a Johnson Controls FEC programmable

direct digital controller with features that allow state

of the art commercial HVAC control. The controller

communicates with Building Automations Systems

that support the BACnet application specific controller

profile. Every Unit has a Device Address, MAC

Address, and baud rate set at the factory to customer

specifications to assure communication compatibility

in the field.

Summary of Contents for ENERVENT+ EVT-09 Series

Page 30: ...30 REVT 05ERV UNIT WIRING DIAGRAM ...

Page 31: ...REVT 05ERV 31 UNIT WIRING DIAGRAM CONTINUED ...

Page 47: ...REVT 05ERV 47 UNIT WIRING DIAGRAM XVIII WIRING DIAGRAMS ...

Page 48: ...48 REVT 05ERV UNIT WIRING DIAGRAM CONTINUED ...

Page 50: ...50 REVT 05ERV Optional Heat Cool Inputs Optional Pre Post Heat ...

Page 57: ...REVT 05ERV 57 DIAGRAM 15 5 1 MODULATION GAS POST HEAT DIAGRAM 14 2 STAGE GAS POST HEAT ...