REVT-05ERV 5

B. OPTIONS and ACCESSORIES

14. DAMPERS

- Parallel-blade, motorized or gravity,

damper assembly for outdoor or exhaust airflow.

Aluminum blades with galvanized steel frames.

15. DEFROST CONTROL

- Three types of frost control

available:

a. Electric pre-heater

b. Exhaust only (low ambient kit)

c. Modulating wheel frost control

Pre-Heater

- An ETL Certified Component, two-stage

heater with controls wired at the factory. Single point

power for the heating elements to be field provided.

16. SUPPLEMENTAL POST-HEAT

- Two post-heaters

are available: Gas Fired (shown) and Electric.

Gas Fired Post-Heat

- An ETL Certified Component.

Standard with aluminized inshot burners, direct spark

ignition, electronic flame sensor, combustion air

inducer, and redundant automatic 2-stage (EVT-28

and larger) gas valve with manual shut-off. Additional

options available are 5:1 modulation and; when a high

turn-down gas input ratio is needed; a split-manifold,

10:1 modulation is recommended to optimize

efficiency at the highest rate. Heat exchanger is

tubular construction, aluminized steel (EVT-10 and

EVT-12 are stainless steel), and life cycle tested.

Stainless steel heat exchanger is an option, but

is required if mixed air temperature is below 45°F.

Electric spark ignition of burners on each operating

cycle. System permits main gas valve to stay open

only when the burners are proven to be lit. Should a

loss of flame occur, gas valve closes, shutting of gas

to burners. Ignition module has LED to indicate status

as troubleshooting aid. Ignition control is factory

installed in heating compartment. Redundant limit

controls are factory installed with fixed temperature

setting. Heat limit controls protect heat exchanger

and other components from overheating. Flame roll-

out switch, flame sensor and combustion air inducer

proving switch protect system operation.

Electric Post-Heat

- An ETL Certified Component,

with controls wired at the factory. Single point power

for the heating elements to be field provided. Staging

ranges from 1 to 4 depending on the unit size and

heater option selected.

17. TEMPERING COILS

- Copper tube and aluminum

fin construction, rated in accordance to ARI Standard

410. Tubing and return bends are seamless copper

conforming to ASTM B75 and ASTM B251 for standard

pressure applications. Designed to withstand 250

psi maximum operating pressures and a maximum

temperature of 300°F. Aluminum fins are Sine Wave

and are die-formed to provide self-spacing collars

which completely cover the entire tube surface.

Copper tubes are mechanically expanded to form an

interference fit with the fin collars.

Chilled and Hot Water

- Design permits in-tube

water velocities up to 6 ft/sec. Headers have factory-

installed air vents and drain plugs placed at the highest

and lowest points respectively. MPT connections are

provided.

Direct Expansion

- All copper tubing is internally

enhanced with Rifled surfacing for improved heat

transfer performance. Factory-installed, externally

adjustable, Thermal Expansion Valve is standard.

Two-stage, interlaced circuiting is provided for the

EVT-46 and larger units with the Neutral Air Option

(

See SECTION VI - TEMPERING MODE

) and for the

EVT-28 and larger with the Neutral Air Plus Option.

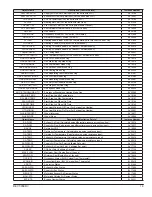

PRODUCT SPECIFICATIONS

- A summary of

specifications for the

E

series is listed in

Table 14. See Page 39.

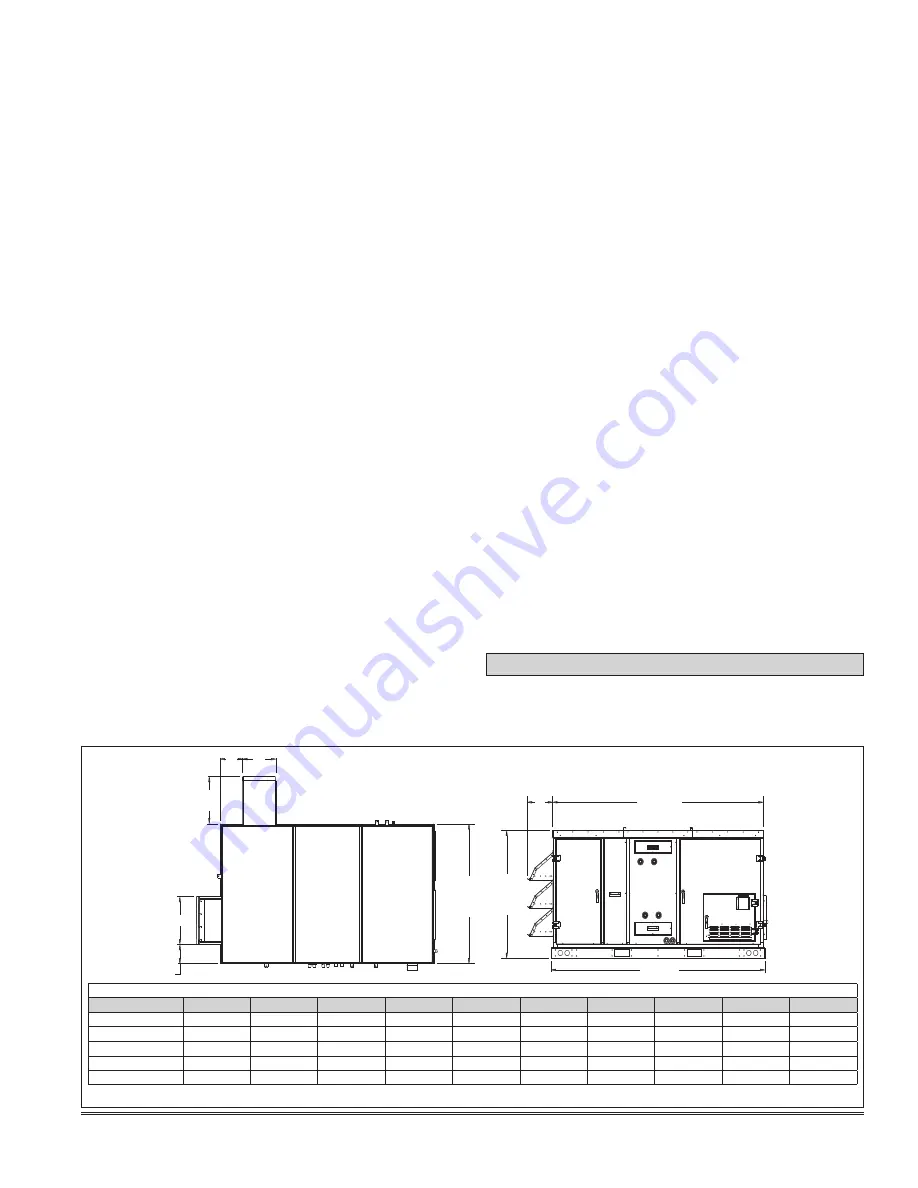

V - DIMENSIONS

Overall unit dimensions are illustrated and tabulated in

Figure 2

.

FIGURE 2 - OVERALL DIMENSIONS

J

H

K

G

F

D

(BASE) B

E

C

A

UNIT OVERALL DIMENSIONS (INCHES)

UNIT

A

B

C

D

E

F

G

H

J

K

EVT-09 / -19

93

1/2

47

3/8

92

1/4

51

3/4

11

1/8

6

5/8

17

3/4

9

14

3/8

18

1/4

EVT-28 / -36

110

7/8

54

3/8

109

5/8

61

5/8

13

7/8

6

3/4

20

8

5/8

15

3/8

18

1/4

EVT-46 / -62

135

1/2

70

134

1/4

79

1/2

17

1/2

7

1/4

24

1/2

11

7/8

20

3/8

18

1/4

EVT-74 / -88

149

1/2

76

7/8

148

90

1/4

19

1/4

11

3/8

29

12

1/4

27

3/4

21

1/4

EVT-10 / -12

161

1/2

88

1/4

160

1/4

101

7/8

21

10

3/4

34

15

3/8

27

3/4

21

1/4

Summary of Contents for ENERVENT+ EVT-09 Series

Page 30: ...30 REVT 05ERV UNIT WIRING DIAGRAM ...

Page 31: ...REVT 05ERV 31 UNIT WIRING DIAGRAM CONTINUED ...

Page 47: ...REVT 05ERV 47 UNIT WIRING DIAGRAM XVIII WIRING DIAGRAMS ...

Page 48: ...48 REVT 05ERV UNIT WIRING DIAGRAM CONTINUED ...

Page 50: ...50 REVT 05ERV Optional Heat Cool Inputs Optional Pre Post Heat ...

Page 57: ...REVT 05ERV 57 DIAGRAM 15 5 1 MODULATION GAS POST HEAT DIAGRAM 14 2 STAGE GAS POST HEAT ...